Self Tapping Sheet Metal Screw Size Guide for Manufacturers and Users

Understanding Self-Tapping Sheet Metal Screw Size Charts

When it comes to fastening materials, self-tapping sheet metal screws are among the most essential components in the construction and manufacturing industries. These screws are designed to drill their own hole while being inserted, which saves time and maintains the structural integrity of the materials being joined. However, with various sizes, materials, coatings, and point styles available in the market, it can be challenging to choose the right type for a specific application. This is where understanding self-tapping sheet metal screw size charts from manufacturers becomes invaluable.

What are Self-Tapping Sheet Metal Screws?

Self-tapping screws are specialized fasteners that eliminate the need for pre-drilling holes. They are particularly effective for fastening metal sheets and other materials without the worry of damaging the substrate. Their unique feature is the pointed tip and the threads that extend all the way to the point, enabling them to create their own hole during installation. This provides significant advantages in terms of efficiency and performance.

Importance of Size Charts

Manufacturers typically provide a self-tapping screw size chart to help customers understand the various dimensions and specifications. The size chart lists essential information such as screw gauge, length, thread type, and head style. Having this information readily available allows users to make informed decisions based on their specific needs.

Key Components of the Size Chart

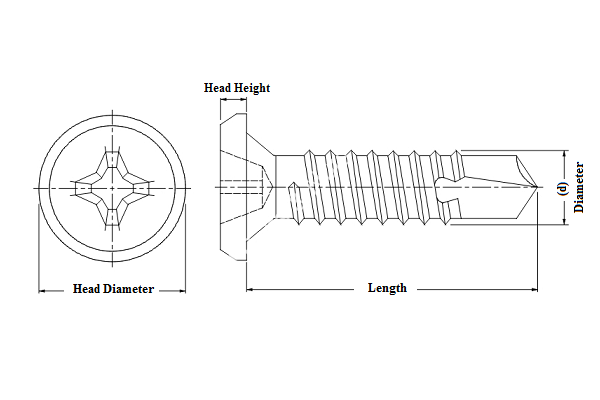

1. Gauge The gauge of the screw refers to its diameter. Common gauges for self-tapping screws range from 4 to 14. The choice of gauge often depends on the thickness and type of the material being fastened.

self tapping sheet metal screw size chart manufacturer

2. Length The length of the screw is critical in determining how deeply the screw will penetrate the material. It ranges typically from ½ inch to 3 inches. Choosing the right length ensures a secure hold without causing any material damage.

3. Thread Type Self-tapping screws can have different types of threads, such as coarse, fine, or self-drilling. Coarse threads are better for softer materials, while fine threads provide better holding strength in harder materials.

4. Head Style There are several head styles available for self-tapping screws, including pan, flat, and oval heads. The style of the head can affect both the aesthetic of the finished project and the screw's performance. For instance, pan heads are ideal for a snug fit, while flat heads offer a flush finish.

5. Material and Coating The material of the screw also plays a crucial role. Common materials include steel, stainless steel, and brass, each chosen based on the environmental conditions and requirements of the application. Furthermore, coatings like zinc plating enhance corrosion resistance, making them suitable for outdoor use.

Choosing the Right Screw

When selecting self-tapping sheet metal screws, consider the project requirements thoroughly. For instance, if you are working with stainless steel sheets, opt for screws made from the same material to ensure compatibility and minimize rusting or galvanic corrosion. If the finished product will be exposed to moisture, choose screws with an appropriate coating.

Conclusion

In summary, understanding self-tapping sheet metal screw size charts provided by manufacturers is crucial for selecting the right fasteners for your projects. By paying close attention to the gauge, length, thread type, head style, and material, you can ensure a successful joinery that meets both structural and aesthetic demands. Whether you are a DIY enthusiast or a professional contractor, having a comprehensive knowledge of screw sizes and specifications will enhance your craftsmanship and project outcomes. Always consult the manufacturer’s charts or guidelines before making your final selection, ensuring that you achieve the best possible results in your applications.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024