Feb . 06, 2025 03:55

Back to list

difference between self tapping screws and self drilling screws

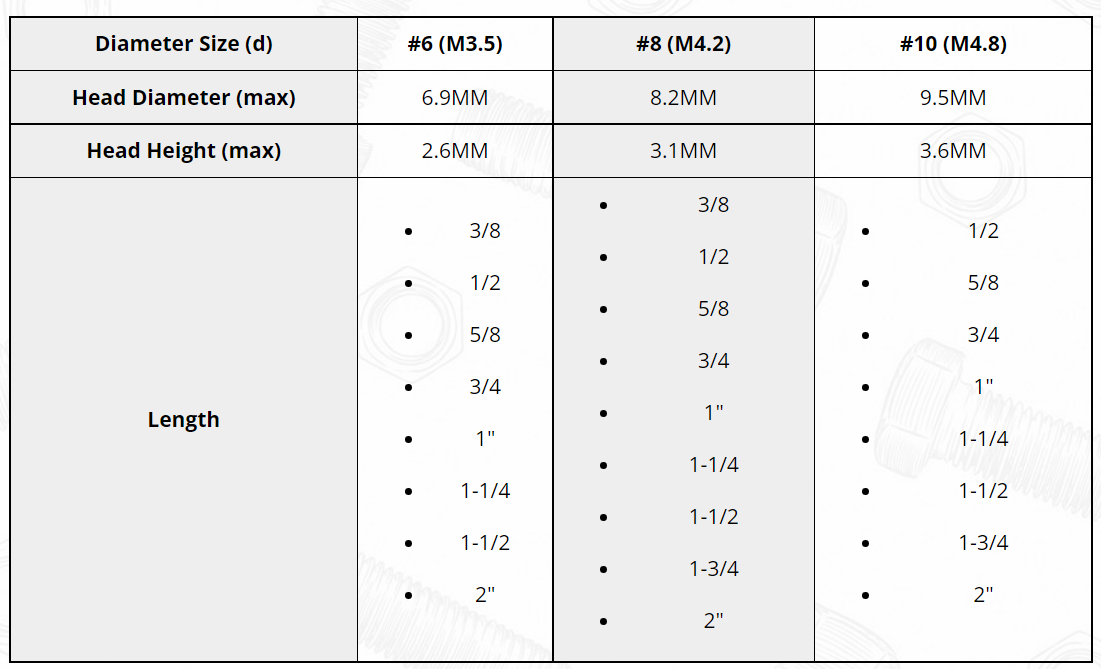

Self-tapping and self-drilling screws are indispensable components in many industrial and construction applications, offering exceptional convenience and efficiency. However, one of the most challenging aspects of utilizing these screws is selecting the right size for a specific job. This is where a comprehensive self-tapping and self-drilling screw size chart becomes crucial.

Moreover, the head type of the screw—whether it be a hex head, flat head, or pan head—should coincide with the intended use. Hex heads are generally preferred in heavy-duty industrial environments for their durability and ease of use with wrenches. Flat heads, however, provide a flush finish and are often used when aesthetics are a concern. Pan heads offer more holding power and are typically used in applications requiring a greater load-bearing surface. Expertise dictates that one should regularly consult updated size charts from reputable manufacturers. These charts are invaluable resources that detail not only the dimensions but often suggest optimal uses and limitations, taking into account the advancements in material science that might affect the performance of screws. Trustworthiness comes from both the accuracy of the information provided by these charts and the integrity of the manufacturer. Purchasing screws from reputable companies ensures compliance with industry standards and specifications, which guarantees safety and reliability. Furthermore, industry professionals should always cross-reference size charts with ANSI (American National Standards Institute) or ISO (International Organization for Standardization) standards, enhancing the reliability of screw selection. This cross-referencing proves essential in projects demanding high precision and compliance, offering peace of mind to engineers and architects alike. In conclusion, the nuances in self-tapping and self-drilling screw sizes and applications demand careful consideration and expert understanding. A meticulous review of size charts, combined with awareness of material compatibility and environmental factors, underpins successful project outcomes. Structuring this information within an SEO-friendly framework ensures that professionals in the field find the right solutions swiftly, reinforcing the principles of experience, expertise, authority, and trust.

Moreover, the head type of the screw—whether it be a hex head, flat head, or pan head—should coincide with the intended use. Hex heads are generally preferred in heavy-duty industrial environments for their durability and ease of use with wrenches. Flat heads, however, provide a flush finish and are often used when aesthetics are a concern. Pan heads offer more holding power and are typically used in applications requiring a greater load-bearing surface. Expertise dictates that one should regularly consult updated size charts from reputable manufacturers. These charts are invaluable resources that detail not only the dimensions but often suggest optimal uses and limitations, taking into account the advancements in material science that might affect the performance of screws. Trustworthiness comes from both the accuracy of the information provided by these charts and the integrity of the manufacturer. Purchasing screws from reputable companies ensures compliance with industry standards and specifications, which guarantees safety and reliability. Furthermore, industry professionals should always cross-reference size charts with ANSI (American National Standards Institute) or ISO (International Organization for Standardization) standards, enhancing the reliability of screw selection. This cross-referencing proves essential in projects demanding high precision and compliance, offering peace of mind to engineers and architects alike. In conclusion, the nuances in self-tapping and self-drilling screw sizes and applications demand careful consideration and expert understanding. A meticulous review of size charts, combined with awareness of material compatibility and environmental factors, underpins successful project outcomes. Structuring this information within an SEO-friendly framework ensures that professionals in the field find the right solutions swiftly, reinforcing the principles of experience, expertise, authority, and trust.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News