Comparison of Self-Tapping Screws and Self-Drilling Screws in Various Applications

Self-Tapping Screws vs. Self-Drilling Screws Understanding the Difference

When it comes to fastening materials together, choosing the right type of screw is critical in ensuring durability and reliability in construction and manufacturing tasks. Two of the most commonly used types of screws are self-tapping screws and self-drilling screws. Though they may sound similar, they serve different purposes and are designed with unique features. This article will delve into the differences between these two types of screws and guide you on when to use each one.

What are Self-Tapping Screws?

Self-tapping screws are designed to create their own hole as they are driven into materials. They come equipped with tapered ends and sharp threads that allow them to penetrate various materials—like metal, plastic, or wood—without requiring a pre-drilled hole. These screws rely on the threads alone to cut through the material and create a secure hold.

Self-tapping screws are available in a variety of shapes, sizes, and materials, making them versatile for different applications. They are commonly used in woodworking, HVAC installations, and automotive assembly. The main advantage of self-tapping screws is that they save time and effort; they eliminate the need for pre-drilling and can be installed rapidly, making them ideal for situations where speed is essential.

What are Self-Drilling Screws?

On the other hand, self-drilling screws take things a step further. These screws feature a pointed tip that is specifically designed to drill into materials, effectively creating a hole as they are driven in. The design typically includes a drill bit-like point that allows the screw to penetrate even harder materials, such as metals, without the need for any pre-drilling.

self tapping screw vs self drilling service

Self-drilling screws are particularly useful in metal-to-metal connections, where precision is key. They are often found in construction applications, particularly for securing roofing, siding, and various metal components. The advantage of self-drilling screws lies in their ease of use; they combine drilling and fastening in one simple action, which can significantly reduce labor and time in assembly processes.

Key Differences

While both self-tapping and self-drilling screws are highly efficient, their core differences make them suitable for different tasks. The main distinction lies in their design and functionality

1. Point Design Self-tapping screws have a sharp tip but rely on threads to create a hole, while self-drilling screws have a drill point that enables them to create a hole directly in harder materials. 2. Material Compatibility Self-tapping screws are more versatile in material choice and can work well in softer materials. In contrast, self-drilling screws excel in conditions where they need to penetrate harder substances, particularly metals.

3. Installation Speed Both screw types speed up installations, but self-drilling screws often provide the convenience of not needing any prior drilling, which can be crucial in time-sensitive projects.

Conclusion

In conclusion, the choice between self-tapping screws and self-drilling screws ultimately depends on the specific requirements of your project. If you're working with softer materials and looking for efficiency, self-tapping screws might be the way to go. However, for applications involving metals or where precision is critical, self-drilling screws are often the better option. Understanding these differences can lead to more effective and durable assemblies in your construction or manufacturing ventures.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

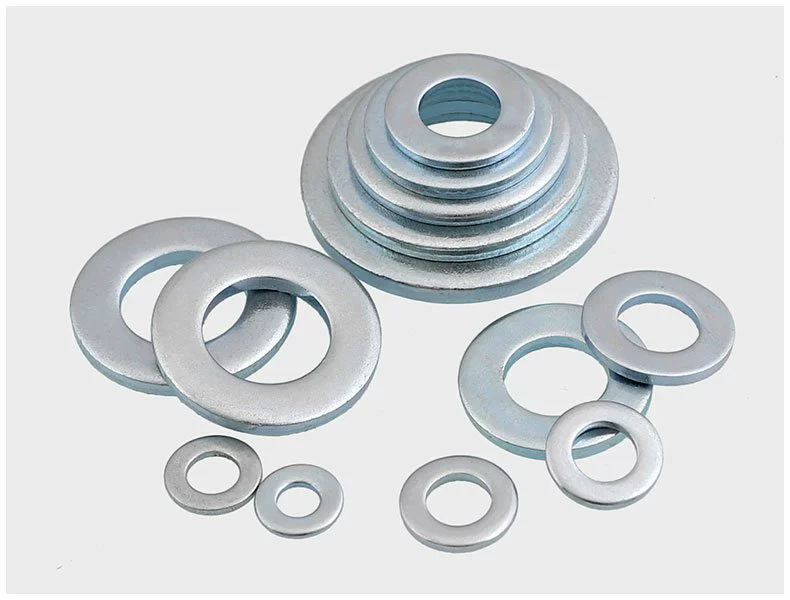

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024