self tapping screw vs self drilling screw pricelist

Self-Tapping Screws vs. Self-Drilling Screws A Price Comparison

When it comes to fasteners, self-tapping screws and self-drilling screws are two popular options that are often utilized in various construction and manufacturing applications. Understanding the differences between these two types of screws can significantly affect project efficiency, costs, and performance. This article explores the characteristics of self-tapping and self-drilling screws, along with a general overview of their price differences.

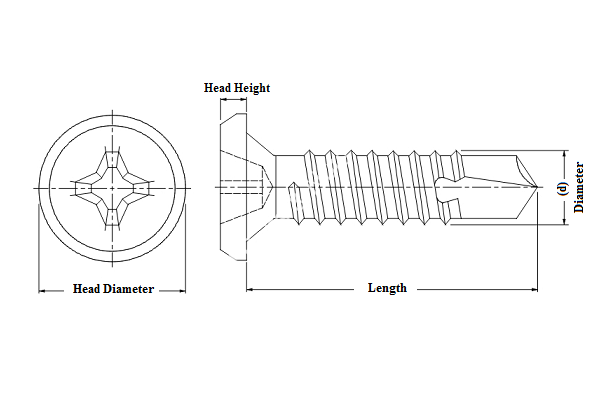

Self-Tapping Screws are designed to create their own hole in a material as they are driven in. They do this by utilizing a sharp, pointed tip that cuts into the substrate, such as wood or metal. These screws are particularly advantageous when working with softer materials. They are typically made from materials like steel or stainless steel, which can affect their price. Their far-reaching application allows them to be used in furniture assembly, metal sheeting, and various types of fixtures.

In contrast, Self-Drilling Screws come with a drilling tip that allows them to both create and fasten without the need to pre-drill a hole. This feature makes them particularly useful for harder materials like steel. Self-drilling screws are particularly favorable in applications such as roofing and metal framing where speed and precision are essential. The added functionality of the drill point generally comes at a higher price, but the time savings can make them very cost-effective for certain projects.

Pricing Dynamics

self tapping screw vs self drilling screw pricelist

The prices for self-tapping and self-drilling screws vary based on several factors, including material, size, coating, and brand. Generally, self-tapping screws are less expensive than self-drilling screws due to their simpler design and manufacturing process. A basic range for self-tapping screws might be around $0.05 to $0.30 each, depending on their specifications. These screws are mass-produced and widely available, contributing to their lower price point.

On the other hand, self-drilling screws typically are priced between $0.15 to $0.60 each. The higher cost can be attributed to the more complex manufacturing processes and the additional functionality provided by the drill point. Furthermore, self-drilling screws are often made from high-strength materials to withstand the demands of drilling into tougher materials and are often used in specialized applications where added strength and durability are required.

Conclusion

When choosing between self-tapping and self-drilling screws, it is important to consider the specific requirements of your project. If you are working with softer materials and need a basic fastener, self-tapping screws can provide a cost-effective solution. However, for applications involving hard materials that require efficient installation, self-drilling screws offer superior performance and justifiable cost.

Ultimately, while self-tapping screws may save you money upfront, the time saved using self-drilling screws can make them a smarter investment in the long run. Always assess the materials, application requirements, and overall budget to make the best choice for your fastening needs. By understanding the distinctions and price dynamics of self-tapping versus self-drilling screws, you can make informed decisions that enhance both the quality and efficiency of your projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024