self tapping screw sizes in mm service

Understanding Self-Tapping Screw Sizes in Millimeters

When it comes to fastening materials together, self-tapping screws play a vital role in various applications, particularly in the construction, automotive, and electronics industries. Unlike traditional screws, self-tapping screws have a unique design that allows them to create their own thread as they are driven into materials, which means they can be used in harder materials, such as metal or wood, without requiring a pre-drilled pilot hole. This article aims to delve into the various sizes of self-tapping screws measured in millimeters, highlighting their applications, types, and considerations for selection.

What are Self-Tapping Screws?

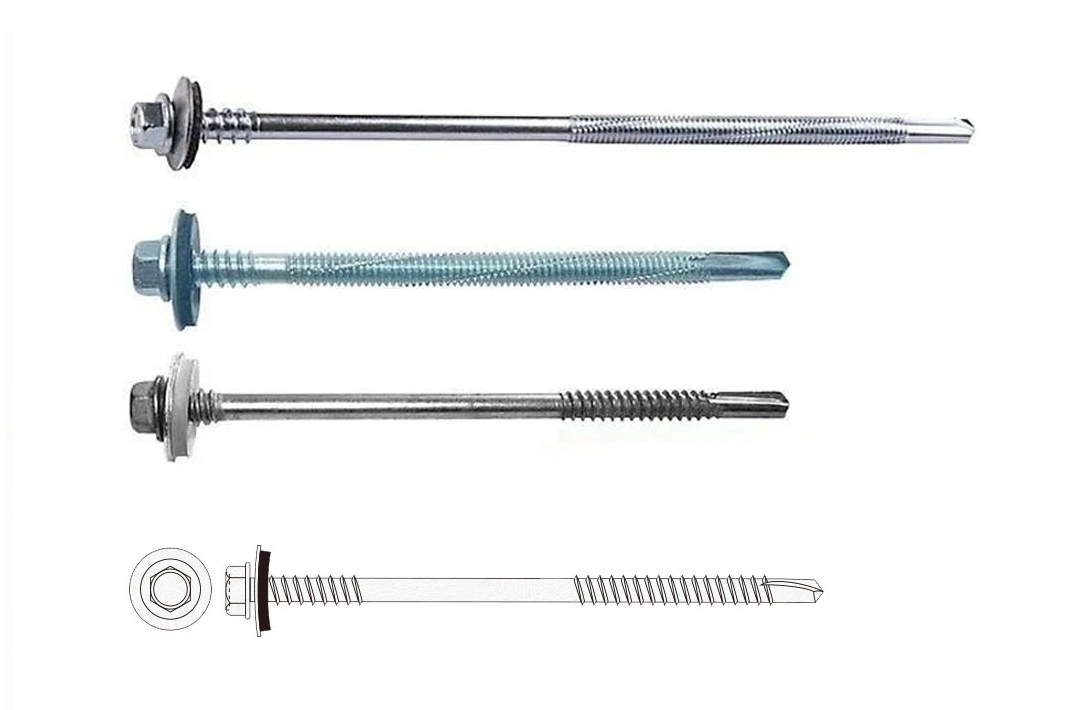

Self-tapping screws are a type of fastener that can tap their own hole while being driven into material, effectively cutting threads into the material for a secure fit. They are designed with sharp points at the tip and threads along the shaft that allows them to create a tight hold. This characteristic makes them particularly useful in situations where speed and efficiency are crucial.

Common Sizes of Self-Tapping Screws

Self-tapping screws come in a variety of sizes, usually specified in metric millimeters (mm). The size of a self-tapping screw typically includes its diameter and length. For example, a screw marked as “M4 x 20” refers to a screw with a nominal diameter of 4 mm and a length of 20 mm.

1. Diameter Sizes Common diameters for self-tapping screws range from M2.5 (2.5 mm) to M12 (12 mm) and sometimes larger for specialized applications. Smaller screws, such as M2 or M3, are typically used for light-duty tasks, while larger sizes, like M8 or M10, are used for heavier applications that require a more substantial fastening force.

2. Length Options The length of self-tapping screws can vary significantly, typically ranging from 10 mm to 100 mm or more. The appropriate length depends on the materials being joined and the thickness of the substrates.

3. Thread Types Self-tapping screws can have different thread types, such as coarse or fine threads. Coarse threads are often used for softer materials because they provide better grip. In contrast, fine threads may be preferred in harder materials where a tighter hold is necessary.

self tapping screw sizes in mm service

Choosing the Right Size

When selecting self-tapping screws, several factors should be considered

- Material The material of the substrates being fastened will dictate the size and type of screw needed. For instance, metal applications might require larger diameter screws with hardened tips.

- Thickness The thickness of the materials being joined is crucial. A rule of thumb is that the screw should penetrate at least half the thickness of the bottom material for a secure hold. Thus, if fastening two pieces of wood that are each 10 mm thick, a screw with a length of at least 20 mm would be ideal.

- Load Requirements Understanding the load that will be placed on the joint is essential. Heavier loads may require larger screws or multiple screws to distribute the load more evenly.

- Environmental Factors Exposure to harsh environments may necessitate corrosion-resistant screws. Stainless steel or coated screws are ideal for outdoor or high-moisture situations.

Conclusion

Self-tapping screws are versatile and essential components in a wide array of construction and assembly tasks. Their availability in varying sizes, typically designated in millimeters, allows for tailored applications that meet specific requirements. Understanding the different sizes, thread types, and factors affecting selection is crucial for achieving optimal fastening results. By selecting the right self-tapping screw, you can ensure strong, reliable, and efficient joins in your projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024