self tapping screw sizes in mm factories

Understanding Self-Tapping Screw Sizes in mm A Comprehensive Guide for Manufacturers

Self-tapping screws are essential fasteners in various industries, including construction, automotive, electronics, and furniture manufacturing. They are designed to create their own threaded hole as they are driven into materials like metal, plastic, or wood. Given the wide range of applications for self-tapping screws, understanding their sizing in millimeters (mm) is crucial for factories and manufacturers seeking to utilize these essential components effectively.

What Are Self-Tapping Screws?

Self-tapping screws are specifically engineered to facilitate easy insertion into materials without the need for a pre-drilled hole. This property saves time and labor costs, making them a popular choice in manufacturing and assembly processes. They are available in numerous sizes, types, and coatings to accommodate various materials and environmental conditions.

The Importance of Size

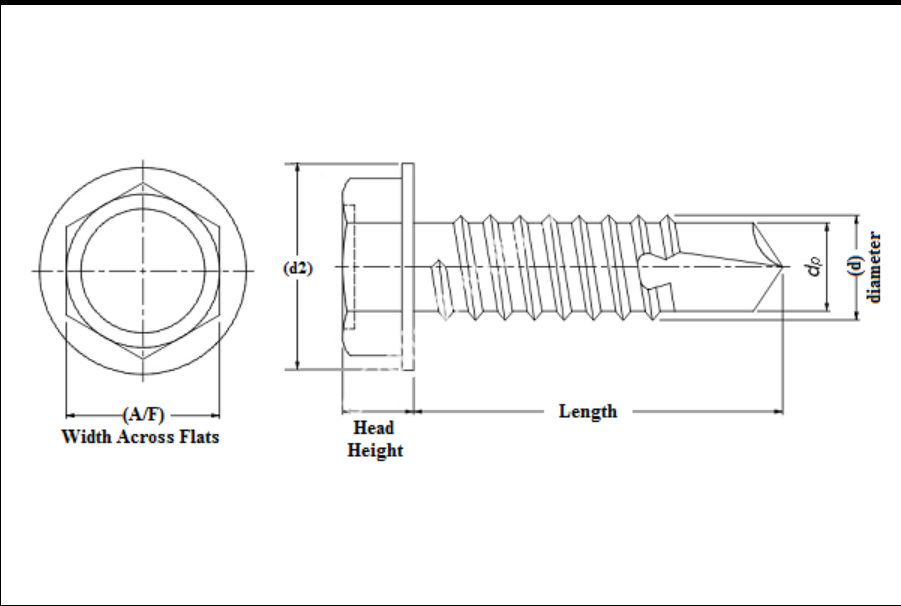

The size of self-tapping screws is typically defined by several key dimensions diameter (gauge), length, and thread count. Understanding these measurements is vital for selecting the right screw for a specific application.

1. Diameter (Gauge) The diameter of a screw is typically represented in mm and determines the thickness of the screw shaft. Common diameters for self-tapping screws range from around 2.0 mm to 12.0 mm, with manufacturers offering various gauges to meet specific needs. The choice of diameter influences the screw's holding strength and the material it can effectively penetrate.

2. Length Length is measured from the underside of the head to the tip of the screw and is crucial for ensuring that the screw penetrates deep enough into the material to create a secure fasten. Common lengths for self-tapping screws vary greatly, typically ranging from 10 mm to 100 mm or more, depending on the application. Selecting the proper length not only ensures adequate grip but also prevents damaging the material being fastened.

3. Thread Count The thread count or pitch affects the screw's grip and holding capacity. Screws with finer threads tend to offer better holding power in softer materials, while coarser threads are more effective in harder materials. In general, self-tapping screws can be found in various thread patterns, including coarse, fine, and partially threaded varieties.

Common Types of Self-Tapping Screws

self tapping screw sizes in mm factories

There are several types of self-tapping screws, each designed for specific materials and applications. The most common types include

- Sheet Metal Screws These are designed for fastening thin sheets of metal and are characterized by their sharp point and thread design, which allows them to tap their own hole.

- Wood Screws With a design that allows for easy penetration into wood, these screws usually have larger heads for a better grip and a more aggressive thread pattern for enhanced holding power.

- Plastics Screws These screws are designed specifically for materials like plastic and feature threads that minimize damage to the workpiece while ensuring a secure hold.

Sourcing and Quality Control

When it comes to manufacturing, sourcing self-tapping screws in the correct size is paramount. Factories should work with reputable suppliers who provide detailed specifications and quality control measures. It is essential to verify that the screws meet international standards, such as ISO or ASTM, to ensure reliability and performance in production processes.

Additionally, factories should consider factors like material grade, coatings, and finishes. For instance, screws with zinc or epoxy coatings offer improved corrosion resistance, making them suitable for outdoor applications or in high-humidity environments.

Conclusion

In conclusion, understanding self-tapping screw sizes in millimeters is fundamental for manufacturers aiming to enhance their production efficiency and ensure product integrity. By carefully considering the diameter, length, and thread count, as well as sourcing from reputable manufacturers, businesses can guarantee that they select the right self-tapping screws for their specific needs. As industries continue to evolve, the importance of these fasteners in various applications will undoubtedly grow, making knowledge about their sizes and specifications an invaluable asset.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024