Guidelines for Determining Metric Self-Tapping Screw Hole Sizes in Manufacturing

Understanding Self-Tapping Screw Hole Sizes A Guide for Manufacturers

Self-tapping screws are an essential component in various manufacturing and construction processes. Their unique design allows the screw to create its own hole as it is driven into materials, eliminating the need for pre-drilled holes. This self-sufficiency makes them particularly valuable in industries where speed and efficiency are critical, such as in automotive, furniture, and appliance manufacturing. However, to ensure optimal performance, it is crucial to understand the appropriate hole size required for self-tapping screws.

The Importance of Proper Hole Size

Selecting the correct hole size is vital for several reasons. Firstly, if the hole is too small, the screw may not be able to penetrate the material, leading to breakage or damage. On the other hand, if the hole is too large, the screw may not have sufficient grip, resulting in a loose fit that can compromise the structural integrity of the assembly. Therefore, manufacturers must adhere to specific guidelines when determining the hole size for self-tapping screws.

Metric Sizing Standards

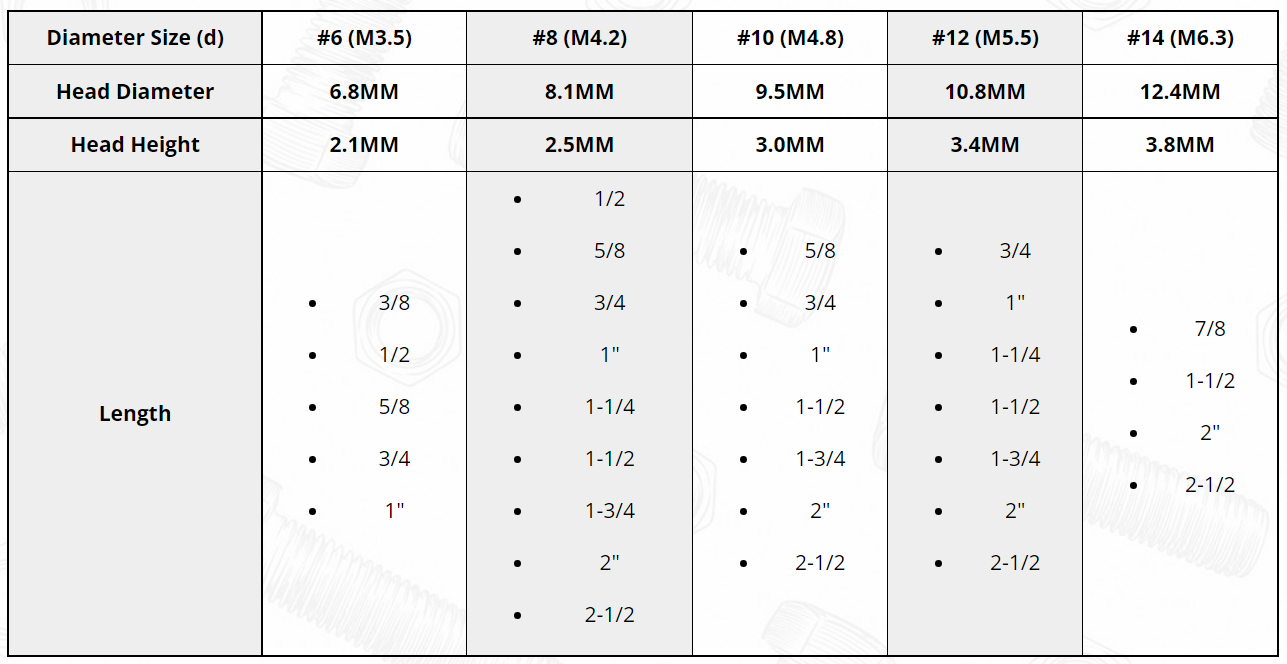

In the context of metric sizing, self-tapping screws are typically categorized based on their diameter and thread pitch. Common sizes include M3, M4, M5, M6, and so forth, with the number representing the nominal diameter in millimeters. The metric system simplifies measurements and offers a standardized method for manufacturers across different countries.

self tapping screw hole size metric factory

For instance, a standard M4 self-tapping screw commonly requires a pilot hole of 2.6 mm to facilitate ease of installation. Similarly, larger screws like the M6 may require hole sizes ranging from 3.5 mm to 4.2 mm, depending on the material being used. It’s advisable for manufacturers to consult the screw manufacturer's specifications to determine the appropriate pilot hole size based on the specific self-tapping screw they plan to utilize.

Material Considerations

The type of material into which the self-tapping screw will be driven heavily influences hole size requirements. Softer materials such as plastic or wood may require smaller pilot holes, while harder materials such as metals or composites may necessitate larger hole sizes for successful tapping. For manufacturers, conducting tests on material compatibility and the performance of different hole sizes can lead to enhanced production efficiency and reduced waste.

Conclusion

In conclusion, understanding the correct hole size for self-tapping screws is crucial for manufacturers seeking to optimize their assembly processes. By adhering to metric sizing standards and considering material characteristics, manufacturers can ensure that their products maintain both durability and functionality. Ultimately, investing time in proper screw and hole size selection will lead to improved product quality and reduced production setbacks, ensuring a smoother workflow in any manufacturing setting. Regular training and updates on industry standards can also empower personnel, making them more adept at choosing the right components for their projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024