self tapping screw holder manufacturers

Self-Tapping Screw Holder Manufacturers Industry Overview

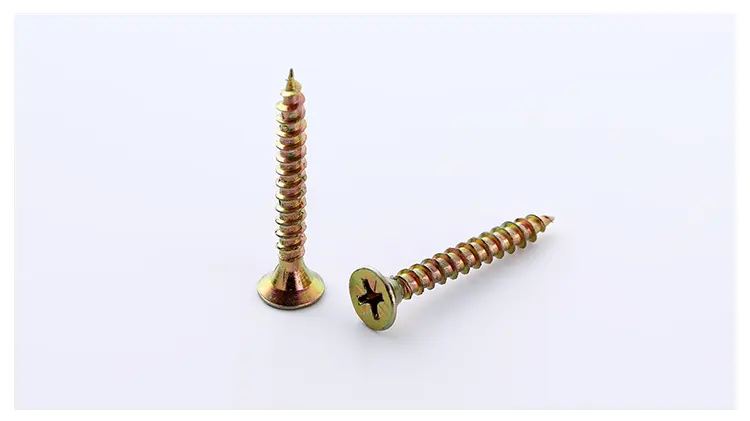

Self-tapping screws play a crucial role in numerous industrial and construction applications. They are designed to create their own hole as they are driven into material, which makes them an optimal choice for situations where pre-drilled holes are not feasible. The significance of self-tapping screws has led to the rise of specialized manufacturers focusing on their production and the corresponding accessories, such as screw holders.

The Importance of Self-Tapping Screw Holders

Self-tapping screw holders are essential tools that enhance the efficiency and safety of using self-tapping screws. These holders securely grip the screw, allowing for improved accuracy during installation. They also protect the screws from dropping and becoming contaminated, which can be particularly important in cleanroom environments or high-precision engineering tasks. Manufacturers producing these holders cater to various industries, including construction, automotive, aerospace, and electronics.

Industry Dynamics

The demand for self-tapping screw holders is driven by the growth of the construction and manufacturing sectors. As industries continue to innovate and expand, the need for reliable and efficient fastening solutions rises in tandem. Self-tapping screws, coupled with their holders, provide the efficiency and reliability that modern production processes require.

Manufacturers of self-tapping screw holders face a range of challenges and opportunities in the current market landscape. The globalization of the supply chain necessitates that manufacturers maintain high standards of quality while also being cost-effective. Additionally, the rapid advancement in technology places pressure on manufacturers to innovate and adapt to new methods and materials, including the integration of automation into their production lines.

Types of Self-Tapping Screw Holders

Self-tapping screw holders come in various designs and sizes to accommodate different types of screws and specific applications. Some of the most common types include

1. Manual Holders These are often used in crafts and DIY projects. They require manual operation and are suited for lighter jobs where control and precision are paramount.

2. Power Holders These holders are designed to work with power tools, allowing for quicker installation and more torque. They are ideal for larger projects or repetitive tasks where speed is a priority.

self tapping screw holder manufacturers

Key Manufacturers in the Industry

Several leading manufacturers specialize in self-tapping screw holders. They vary in size and focus, from large multinational corporations to smaller specialized companies. Some notable brands are

- Fastenal Known for a wide array of fastening solutions, Fastenal produces high-quality holders that cater to both industrial and commercial markets.

- Hilti Focusing on construction and building maintenance, Hilti offers innovative solutions, including advanced screw holders that integrate seamlessly with their tools.

- DeWalt An established name in power tools, DeWalt also manufactures accessories, including holders designed specifically for their drilling and fastening tools.

- Bosch Renowned for its engineering excellence, Bosch produces robust and reliable self-tapping screw holders that are compatible with their vast range of power tools.

Future Trends

As technology continues to advance, the self-tapping screw holder industry is likely to experience several transformative trends. The integration of smart technology, such as RFID tracking and automated workflows, could enhance inventory management and improve operational efficiency. Sustainability and the use of eco-friendly materials are also becoming increasingly important, with manufacturers exploring ways to reduce their environmental impact.

Conclusion

Self-tapping screw holders are an indispensable part of the fastening industry. With a diverse array of manufacturers and ongoing technological advancements, the market for these tools is poised for growth and innovation. As industries evolve and demand for efficient solutions continues to rise, self-tapping screw holder manufacturers will play a crucial role in shaping the future of construction and manufacturing processes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024