self tapping screw head size products

Understanding Self-Tapping Screw Head Sizes A Comprehensive Guide

When it comes to assembly and construction, self-tapping screws are among the most versatile and efficient fasteners available. They are designed to create their own mating thread in materials, eliminating the necessity for pre-drilling. However, one key aspect that often gets overlooked is the size and type of the screw head, which can significantly influence both functionality and aesthetic appeal. In this article, we will explore the various types of self-tapping screw head sizes and their respective applications.

Types of Self-Tapping Screw Heads

Self-tapping screws come with a variety of head styles, each serving a unique purpose. The most common types include

1. Flat Head This style is countersunk, allowing it to sit flush with the surface. It is ideal for applications where a smooth finish is essential, such as in woodworking or on surfaces that will be painted.

2. Pan Head With a slightly rounded top, pan head screws are commonly used in areas where there is a need for a larger bearing surface. They provide good clamping force and are great for use in metal or plastic applications.

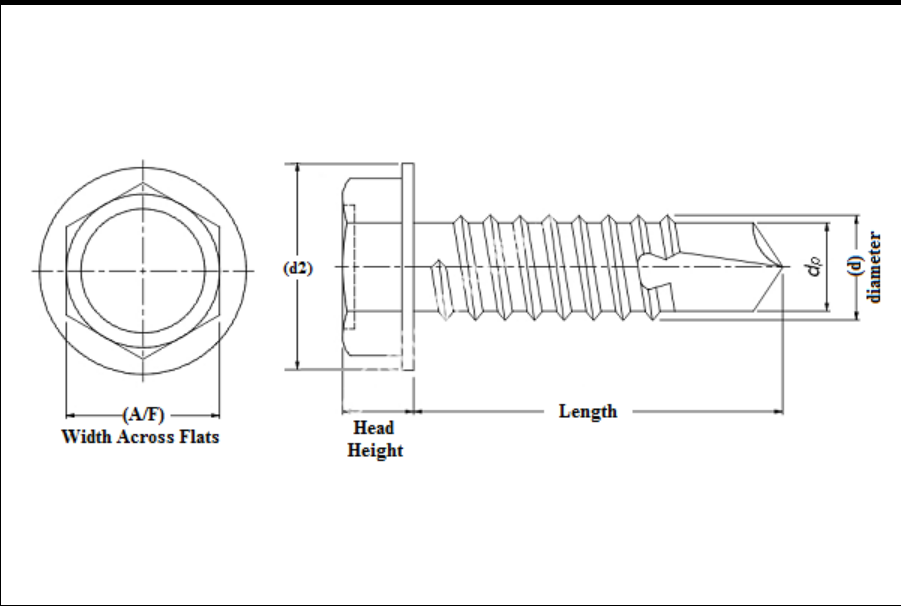

3. Hex Head Designed to be driven by a wrench, hex heads are popular in automotive and heavy-duty applications. Their larger size makes them less likely to strip when significant torque is applied.

4. Socket Head Featuring a cylinder that allows for a hex key to fit inside, socket head screws provide a clean look and are ideal for tight spaces where traditional screwdrivers cannot reach.

5. Round Head These screws have a domed top and are often used in applications that require higher strength. They are often seen in soft materials, where their head shape can help distribute forces more evenly.

Sizing Importance

The size of the screw head is critical in determining the screw's effectiveness and suitability for specific applications

. Factors to consider includeself tapping screw head size products

- Head Diameter A larger diameter provides a broader surface for better load distribution. However, this can also affect the aesthetic if a large screw is used in a visible area.

- Head Height Tall heads may provide more grip but can also protrude more than a lower head, which might not be desirable in some designs.

- Drive Type The selection of head size can affect which tools can be used for installation. For instance, Phillips or slotted heads might not provide the same torque as a hex or Torx head.

Choosing the Right Size

When selecting the appropriate self-tapping screw head size, consider the following

1. Material The material you are working with plays a large role in size selection. Softer materials may benefit more from screws with larger heads for better grip, while harder materials may not require as large a screw.

2. Use Case For applications that will bear significant stress, opt for screws with smaller, stronger heads that can handle high torque. Conversely, for aesthetic applications, choose screw heads that will sit flush and provide a clean look.

3. Tool Availability Ensure that you have the right tools available for the selected screw head type. Using the wrong tool can lead to stripping or damaging the screw.

Conclusion

Understanding the various self-tapping screw head sizes and their implications is crucial for anyone involved in construction, woodworking, or metalworking. By choosing the right type and size of screw head, you not only enhance the efficiency of your work but also ensure a polished and professional finish to your projects. Whether you are a DIY enthusiast or a seasoned professional, making informed selections about self-tapping screws can elevate your craftsmanship to the next level.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024