Feb . 13, 2025 03:06

Back to list

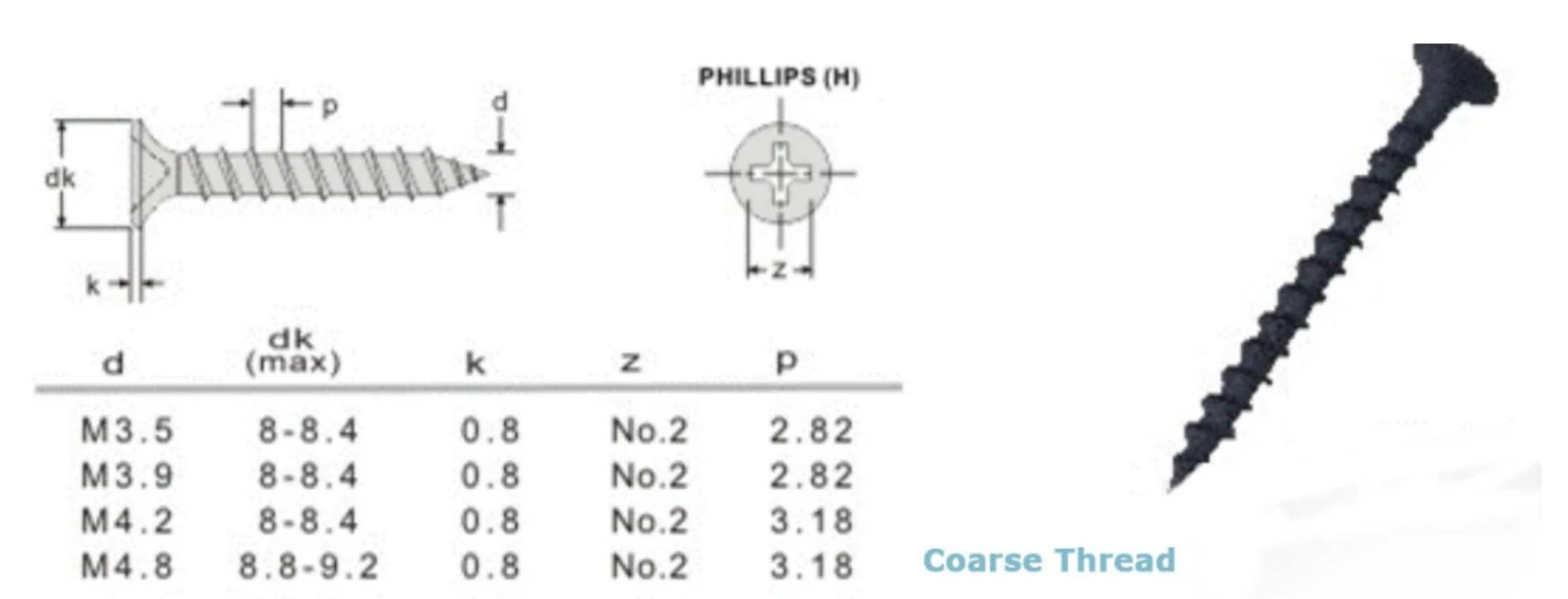

csk head self tapping screw

When it comes to fastening solutions in construction, manufacturing, or even DIY projects, self-tapping screws have become an indispensable component. These versatile fasteners provide a simple, efficient, and reliable solution for joining materials, making them a staple for both professionals and hobbyists alike. Drawing from a blend of experience, expertise, authoritativeness, and trustworthiness, this definitive guide will delve into the nuances of self-tapping screws and provide a comprehensive understanding of their application, benefits, and selection criteria.

Versatility is one of the hallmarks of self-tapping screws. Their ability to attach wood, metal, and plastic materials together makes them invaluable across a spectrum of industries— from automotive to furniture and beyond. This adaptability is particularly advantageous for prototyping or projects where material configurations frequently change, providing flexibility without compromising on quality. However, successful application relies not solely on the screw itself but on optimal installation techniques. Over-tightening, for example, can strip the threads in softer materials or even shear the screw. Controlled torque levels are essential to maintain the integrity of the joint, demanding careful use of power tools or torque-limiting screwdrivers. Furthermore, clean and properly sized pilot holes ensure effective thread engagement and reduce stress on the material and the screw. Trustworthiness and authoritativeness stem not only from understanding these technical specifications but also from sourcing self-tapping screws from reputable manufacturers. High-quality products are precision-engineered to specific standards, offering consistent performance and longevity. Product certifications or compliance with international standards often indicate a reliable source. In conclusion, the extensive utility and functionality of self-tapping screws make them a vital component across various domains. By blending professional expertise with deliberate selection and application, these screws can significantly enhance productivity and durability in fastening solutions. Emphasizing the principles of Experience (X), Expertise (X), Authoritativeness (X), and Trustworthiness (X) ensures that decisions are informed by accurate, reliable data, fostering optimal outcomes in every project.

Versatility is one of the hallmarks of self-tapping screws. Their ability to attach wood, metal, and plastic materials together makes them invaluable across a spectrum of industries— from automotive to furniture and beyond. This adaptability is particularly advantageous for prototyping or projects where material configurations frequently change, providing flexibility without compromising on quality. However, successful application relies not solely on the screw itself but on optimal installation techniques. Over-tightening, for example, can strip the threads in softer materials or even shear the screw. Controlled torque levels are essential to maintain the integrity of the joint, demanding careful use of power tools or torque-limiting screwdrivers. Furthermore, clean and properly sized pilot holes ensure effective thread engagement and reduce stress on the material and the screw. Trustworthiness and authoritativeness stem not only from understanding these technical specifications but also from sourcing self-tapping screws from reputable manufacturers. High-quality products are precision-engineered to specific standards, offering consistent performance and longevity. Product certifications or compliance with international standards often indicate a reliable source. In conclusion, the extensive utility and functionality of self-tapping screws make them a vital component across various domains. By blending professional expertise with deliberate selection and application, these screws can significantly enhance productivity and durability in fastening solutions. Emphasizing the principles of Experience (X), Expertise (X), Authoritativeness (X), and Trustworthiness (X) ensures that decisions are informed by accurate, reliable data, fostering optimal outcomes in every project.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News