self tapping screw dimensions chart quotes

Understanding Self-Tapping Screw Dimensions A Comprehensive Guide

Self-tapping screws are critical components in various applications, from automotive to construction and everyday household items. Their unique design allows them to create their own hole in a material, which can be particularly advantageous in situations where pre-drilling would be impractical. Understanding the dimensions of self-tapping screws is essential for anyone working with them, whether in manufacturing, DIY projects, or repair work.

What are Self-Tapping Screws?

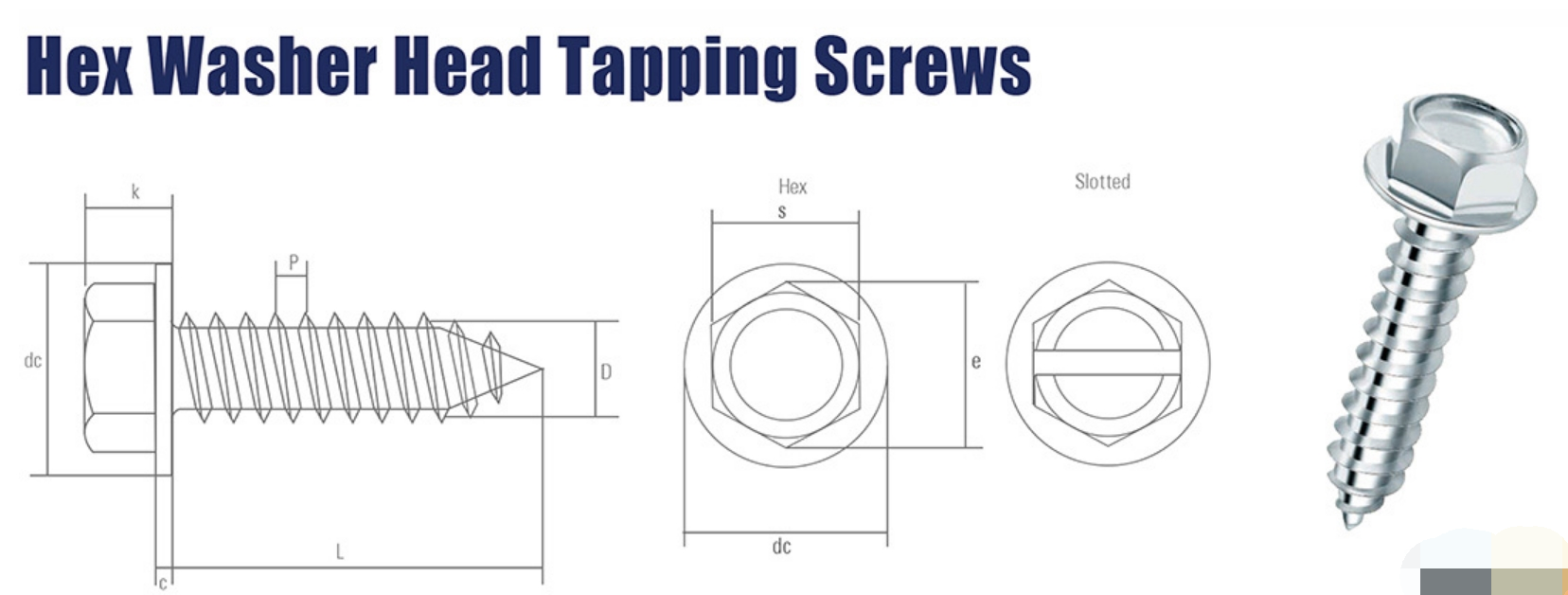

Self-tapping screws are designed with a sharp tip and threads that allow them to embed themselves into hard materials without the need for a pre-drilled hole. They come in various types, each suited for different applications, including sheet metal screws, wood screws, and plastic screws. The dimensions of these screws are crucial as they determine the screw's performance, compatibility with materials, and overall effectiveness in a specific application.

Key Dimensions

1. Diameter The diameter of a self-tapping screw is one of the most critical dimensions as it influences the screw's grip and load-bearing capacity. Typically, self-tapping screws range from 1.6 mm (0.063 inches) to 6 mm (0.236 inches) or more. The diameter should be chosen based on the material thickness and the required strength of the joint.

2. Length The length of the screw is another vital factor. Self-tapping screws come in various lengths, from a short 6 mm (0.24 inches) to longer screws exceeding 100 mm (4 inches). When selecting a screw length, consider the thickness of the material being joined. The screw should penetrate deep enough to ensure a secure hold without protruding excessively.

self tapping screw dimensions chart quotes

3. Thread Pitch The thread pitch refers to the distance from one thread to the next and is crucial for the screw's strength and ability to grip the material. Common pitches for self-tapping screws vary based on size, and understanding this aspect helps in selecting the right screw for different material types.

4. Head Type Self-tapping screws come in various head styles, including pan, flat, oval, and hex heads. Each style serves a different purpose. For example, a flat head may be used where a flush finish is required, while a hex head might be appropriate for applications requiring high torque.

5. Material and Coating The material from which a self-tapping screw is made also influences its dimensions and overall durability. Common materials include stainless steel, carbon steel, and plated materials for corrosion resistance. Selecting the correct coating can enhance the screw's longevity and suitability for different environments.

Choosing the Right Self-Tapping Screw

Selecting the appropriate self-tapping screw involves considering the project requirements, including material types, load-bearing needs, environmental factors, and aesthetic preferences. It is crucial to refer to a self-tapping screw dimensions chart, which provides standardized measurements and guides users in choosing the right size and type for their specific application.

Conclusion

In summary, understanding self-tapping screw dimensions is essential for achieving effective and reliable fastening. With their ability to eliminate the need for pre-drilling, they offer convenience and efficiency in various projects. By paying close attention to details such as diameter, length, thread pitch, head type, and material, users can ensure that they select the right screws for their needs. Whether you are a professional or a DIY enthusiast, having a solid grasp of these dimensions will enhance the quality and durability of your work. Always refer to a comprehensive dimensions chart to help guide your choices for optimal results.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024