Feb . 12, 2025 20:42

Back to list

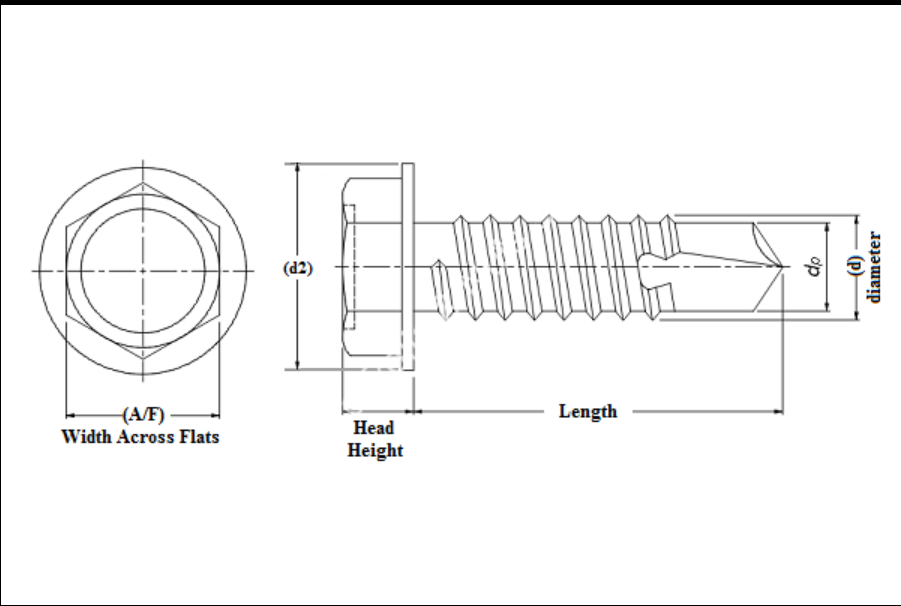

self tapping screw diameter chart

Understanding the various specifications of self-tapping screws, including diameter charts, is crucial for selecting the right screw for a specific application. These tiny components are giants in their role, offering secure fastening in numerous industries, from construction to aeronautics. As experts with years of experience in the fastener industry, we provide here a deep dive into self-tapping screw diameter charts, tailored for professionals seeking precision and reliability.

Moreover, understanding the material each screw type is best suited for can fortify your decision basis. Stainless steel screws, for example, are highly resistant to corrosion and are preferable in marine environments or for outdoor applications. Carbon steel screws, on the other hand, might be selected for their superior strength and coating flexibility, suitable for industries that value heavy-duty applications. With the globalization of manufacturing standards, users must familiarize themselves with both metric and imperial measurement concepts concerning self-tapping screws. Metric diameters might range from M2, M3, M4, up to larger standards like M10 and beyond, used commonly in European and Asian markets. Conversely, in North America, sizes indicated in gauge numbers, such as 4, 6, or 8, cater to the imperial understanding. The importance of quality materials and precise manufacturing cannot be over-emphasized and is crucial in determining the screw's ability to self-tap effectively without degrading its structure integrity. Always source screws from reputable manufacturers that adhere to international standards like ISO, ANSI, or DIN, ensuring a consistent basis for performance and safety. As industry professionals deeply invested in fastening solutions, we encourage collaboration with engineers and suppliers. Consulting resources like technical guides, online databases, and directly communicating with manufacturers can provide enhanced insights into product specifics beyond the charts. Adopting a pragmatic approach in this way supports informed decision-making, driven by experience, technical expertise, and trustworthiness. To conclude, self-tapping screw diameter charts are indispensable tools for experts dedicated to ensuring structural integrity and durability in their projects. A meticulous approach to understanding these charts, aligned with material specifications and usage contexts, affirms the reliability and effectiveness of fastening operations. Let this foundation of knowledge serve as a blueprint for precision and excellence in your fastening endeavors.

Moreover, understanding the material each screw type is best suited for can fortify your decision basis. Stainless steel screws, for example, are highly resistant to corrosion and are preferable in marine environments or for outdoor applications. Carbon steel screws, on the other hand, might be selected for their superior strength and coating flexibility, suitable for industries that value heavy-duty applications. With the globalization of manufacturing standards, users must familiarize themselves with both metric and imperial measurement concepts concerning self-tapping screws. Metric diameters might range from M2, M3, M4, up to larger standards like M10 and beyond, used commonly in European and Asian markets. Conversely, in North America, sizes indicated in gauge numbers, such as 4, 6, or 8, cater to the imperial understanding. The importance of quality materials and precise manufacturing cannot be over-emphasized and is crucial in determining the screw's ability to self-tap effectively without degrading its structure integrity. Always source screws from reputable manufacturers that adhere to international standards like ISO, ANSI, or DIN, ensuring a consistent basis for performance and safety. As industry professionals deeply invested in fastening solutions, we encourage collaboration with engineers and suppliers. Consulting resources like technical guides, online databases, and directly communicating with manufacturers can provide enhanced insights into product specifics beyond the charts. Adopting a pragmatic approach in this way supports informed decision-making, driven by experience, technical expertise, and trustworthiness. To conclude, self-tapping screw diameter charts are indispensable tools for experts dedicated to ensuring structural integrity and durability in their projects. A meticulous approach to understanding these charts, aligned with material specifications and usage contexts, affirms the reliability and effectiveness of fastening operations. Let this foundation of knowledge serve as a blueprint for precision and excellence in your fastening endeavors.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News