Self Drilling Wafer Head Screws 10-16 x 1-1/4 inch with Star Drive Design

Understanding Self-Drilling Wafer Head Screws A Closer Look at the 10-16 x 1-1/4 Star Design

In the world of construction and manufacturing, the choice of fasteners can significantly impact the quality and durability of the final product. One particular type that has gained prominence is the self-drilling wafer head screw, particularly the 10-16 x 1-1/4 variant featuring a star drive. This article will delve into the characteristics, advantages, and applications of this versatile fastener.

What Are Self-Drilling Wafer Head Screws?

Self-drilling screws are designed to drill their own holes as they are driven into materials, eliminating the need for pre-drilling. This feature is particularly useful in various construction and assembly applications, as it saves time and labor costs. The wafer head screw, characterized by its wide, flat head reminiscent of a washer, provides a larger bearing surface. This design minimizes the risk of damage to the materials being fastened and helps distribute the load more evenly.

The Specifications of 10-16 x 1-1/4 Screws

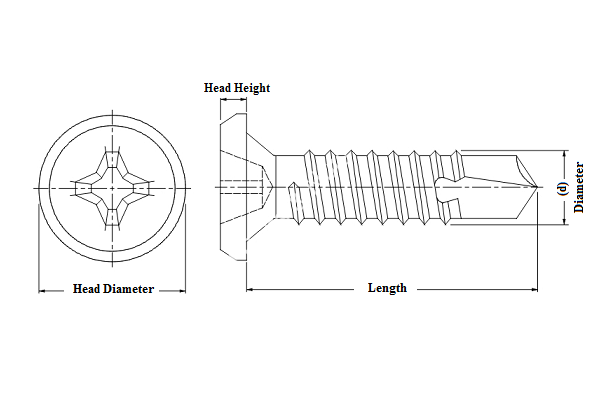

The numbers in the designation 10-16 x 1-1/4 refer to the screw's size and length. The first part, 10-16, indicates the screw diameter and thread count, suitable for medium to heavy-duty applications. The second part, 1-1/4, signifies the length of the screw, which is approximately 1.25 inches. This makes it ideal for fastening materials that require a deeper penetration compared to shorter screws.

Advantages of Using Self-Drilling Wafer Head Screws

1. Efficiency Self-drilling screws eliminate the need for pilot holes, streamlining the fastening process. This is especially advantageous in large-scale construction projects where speed is crucial.

self drilling wafer head screw 10-16 x 1-1 4 star

2. Versatility These screws can be used on a wide range of materials, including metal, wood, and plastic. Their design is particularly effective for applications involving sheet metal or when fastening different materials together.

3. Stronger Connections The wafer head's design offers superior load distribution, reducing the risk of stripping or snapping under stress. This ensures a reliable and robust connection, which is vital in construction and manufacturing.

4. Reduced Labor Costs By minimizing the need for pre-drilling and simplifying the fastening process, these screws can lead to significant labor cost savings.

Applications

Self-drilling wafer head screws are utilized in various industries, including construction, automotive, and appliance manufacturing. They are commonly used for

- Attaching metal siding and roofing panels. - Fastening insulation and other components in HVAC systems. - Joining structural elements in the fabrication of industrial equipment.

Conclusion

In summary, the 10-16 x 1-1/4 self-drilling wafer head screw with a star drive is a powerful tool in any builder's or manufacturer's toolkit. Its innovative design, which combines efficiency with strong, reliable performance, makes it an ideal choice for a wide array of applications. As industries continue to seek ways to optimize processes and reduce costs, fasteners like these play a crucial role in achieving those goals. Whether you're a professional contractor or a DIY enthusiast, understanding the benefits and utilization of self-drilling wafer head screws can greatly enhance your projects' success.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024