self drilling screw hex washer head products

Understanding Self-Drilling Screws with Hex Washer Heads

Self-drilling screws, often referred to as self-tappers, are an essential component in various construction and manufacturing applications. Among the different designs of these screws, the hex washer head variant stands out for its unique features and advantages. In this article, we will explore the benefits, uses, and design elements of self-drilling screws with hex washer heads.

What Are Self-Drilling Screws?

Self-drilling screws are specialized fasteners that come equipped with a drill point at the tip, allowing them to bore through materials without requiring a pre-drilled pilot hole. This feature significantly streamlines the assembly process, leading to time and labor savings. Typically made from steel or stainless steel, these screws are designed for use in various materials, including wood, metal, and plastic, making them versatile options in construction, automotive, and DIY projects.

The Hex Washer Head Design

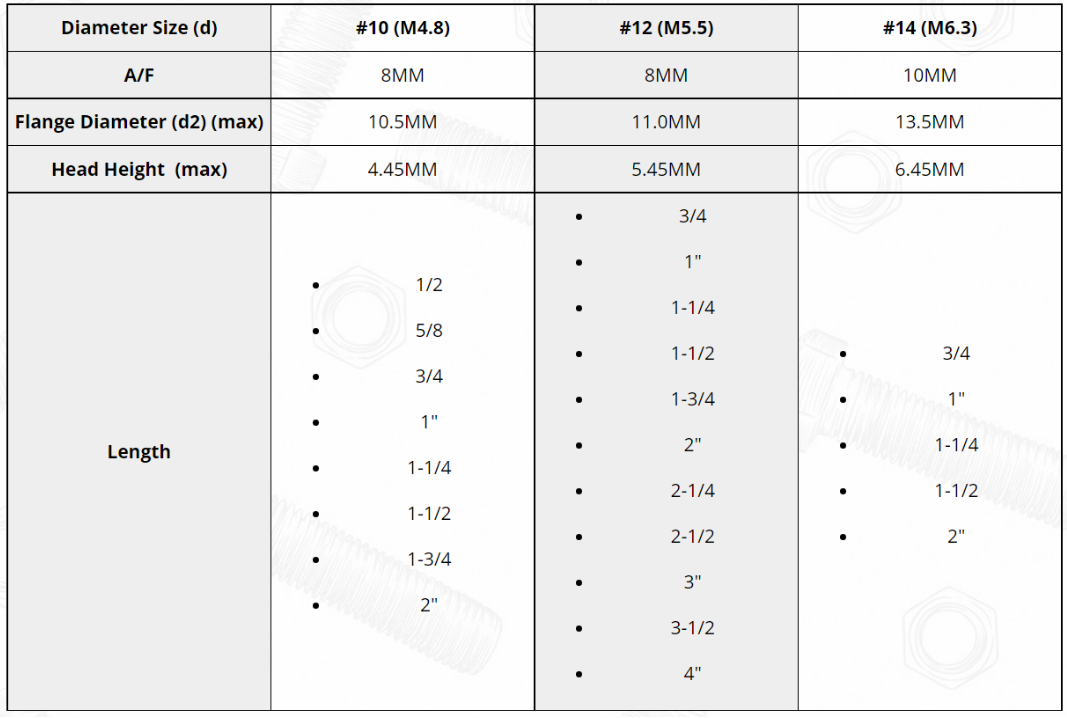

The hex washer head is one of the most popular head styles for self-drilling screws. It consists of a wide, flat bearing surface, which provides excellent load distribution. The hexagonal shape allows for easy fastening with a wrench or socket, providing more torque and reducing the risk of stripping the head compared to traditional slotted or Phillips heads. This feature is particularly useful in high-torque applications where a strong grip is essential.

One of the significant advantages of the hex washer head is its built-in washer feature. This washer helps to create a seal when the screw is driven, effectively reducing the risk of water leakage and corrosion. This characteristic makes self-drilling screws with hex washer heads especially suitable for outdoor and industrial applications, where exposure to the elements can lead to deterioration.

Applications of Self-Drilling Screws with Hex Washer Heads

The versatility of self-drilling screws with hex washer heads means they are used across multiple industries. Here are some common applications

1. Metal Fabrication They are widely used in metal-to-metal applications, including the assembly of steel structures, canopies, and brackets. The self-drilling feature allows for quick assembly without the need for pre-drilling.

self drilling screw hex washer head products

2. Roofing and Siding These screws are ideal for securing metal panels in roofing and siding applications. The hex washer head provides a reliable seal, preventing moisture from entering. This is crucial in maintaining structural integrity and preventing water damage.

3. Automotive Industry In automotive manufacturing and repairs, self-drilling screws with hex washer heads are used to fasten metal body parts and components. Their ability to self-tap into metal makes them indispensable on production lines and in garages.

4. Construction They are commonly utilized in wood framing, deck installations, and other construction projects where fastening wood and metal together is required. Their ease of use and reliable performance make them a favorite among contractors.

Advantages of Self-Drilling Screws with Hex Washer Heads

1. Efficiency The self-drilling feature eliminates the need for pilot holes, saving time on installation.

2. Strength and Durability Made from high-strength materials, these screws are designed to withstand heavy loads and harsh conditions, making them ideal for long-term projects.

3. Corrosion Resistance Many hex washer head screws are treated or coated to resist rust and corrosion, making them suitable for outdoor use.

4. Labor Saving Their design and ease of use reduce the need for multiple tools, allowing for faster completion of projects and reduced labor costs.

Conclusion

Self-drilling screws with hex washer heads are a vital component in modern construction and manufacturing. Their innovative design combines strength, efficiency, and versatility, making them an excellent choice for a wide range of applications. Whether you're securing metal roofing, assembling automotive components, or working on a DIY project, these screws provide the reliability and performance needed to get the job done right. As industries continue to evolve, the demand for such effective fasteners will undoubtedly grow, underlining the importance of understanding their features and applications.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024