Self-Drilling Screws for Roofing Exporters and Their Market Opportunities

Self-Drilling Screws for Roofing A Comprehensive Overview for Exporters

In the construction and roofing industry, self-drilling screws have gained considerable popularity due to their efficiency, ease of use, and durability. These screws are specifically designed to drill their own holes in materials without the need for pre-drilling, making them an ideal choice for roofing applications. As the demand for these fasteners grows, the export market for self-drilling screws is becoming increasingly significant. In this article, we will explore the features, benefits, and considerations for exporters in the self-drilling screw industry.

Understanding Self-Drilling Screws

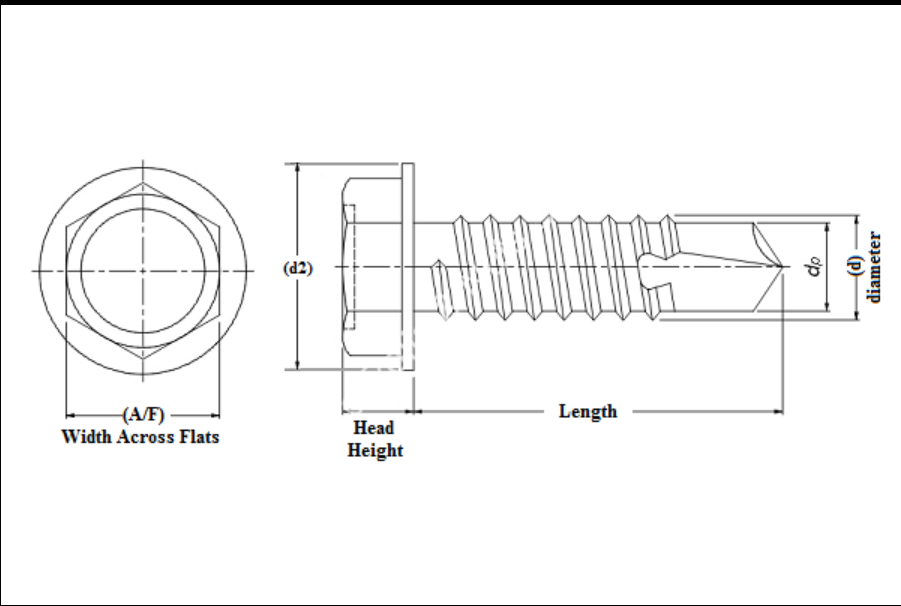

Self-drilling screws, also known as tek screws, come with a drill bit-shaped tip that allows them to penetrate materials such as metal, wood, and plastic without the need for a pilot hole. This unique design streamlines the installation process, significantly reducing labor costs and time. Made from high-strength steel with protective coatings, these screws are engineered to withstand harsh environmental conditions, making them suitable for various roofing applications.

Key Features

1. Material Composition Self-drilling screws are typically made from steel, often galvanized or coated with zinc, to enhance corrosion resistance. Some screws may also have additional coatings to improve longevity and performance in specific environments.

2. Design Versatility Available in a variety of head types, thread designs, and lengths, self-drilling screws can be tailored to meet the specific needs of different roofing materials. This versatility makes them suitable for both residential and commercial roofing projects.

3. Installation Efficiency The self-drilling feature eliminates the need for pre-drilling, allowing for faster installation. This is particularly advantageous in large-scale roofing projects, where time savings can result in significant overall cost reductions.

Benefits of Using Self-Drilling Screws in Roofing

- Cost-Effective By reducing installation time and labor costs, self-drilling screws can significantly lower the overall expenses associated with roofing projects

. This factor makes them an attractive option for contractors and builders looking to maximize profitability.self drilling screw for roofing exporters

- Enhanced Performance Self-drilling screws are designed to provide superior holding power, which is crucial for maintaining the integrity of roofing systems. Their ability to create a secure fit ensures that roofing materials are firmly anchored, reducing the likelihood of damage from wind or other environmental factors.

- Improved Weather Resistance High-quality self-drilling screws offer excellent resistance to rust and corrosion, even in challenging weather conditions. This characteristic is essential for prolonging the lifespan of roofing systems, ultimately providing better value to customers.

Considerations for Exporters

As an exporter of self-drilling screws, it’s vital to be aware of various factors that can influence market success

1. Quality Standards Adhere to international quality certifications such as ISO and ASTM to ensure your products meet the expectations of international buyers. Quality assurance not only builds trust but also distinguishes your products in a competitive market.

2. Market Research Understanding the specific needs and preferences of target markets is crucial. Conducting thorough market analyses can help identify the most suitable designs, materials, and sizes that align with local construction practices.

3. Logistics and Regulations Familiarize yourself with import/export regulations, tariffs, and shipping logistics for each target market. Efficient management of these aspects can streamline operations and enhance customer satisfaction.

4. Sustainability Practices With an increasing global focus on sustainability, incorporating eco-friendly practices in production and packaging can appeal to environmentally conscious buyers, potentially opening new market opportunities.

Conclusion

Self-drilling screws are an invaluable component in the roofing industry, offering efficiency, durability, and cost-effectiveness. For exporters looking to enter or expand within this niche market, understanding the unique features and benefits of these screws is crucial. By focusing on quality, market research, logistics, and sustainability, exporters can position themselves for success in the growing global demand for roofing solutions. As the industry evolves, so too will the opportunities, and the ability to adapt to changing market needs will determine long-term success in exporting self-drilling screws.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024