self drilling screw for metal factories

Understanding Self-Drilling Screws for Metal Factories

In the realm of construction and manufacturing, fasteners play a crucial role in ensuring structural integrity and reliability. Among these, self-drilling screws have gained immense popularity, especially in metal factories where efficiency and strength are paramount. This article delves into the characteristics, applications, and advantages of self-drilling screws, highlighting their significance in metalworking environments.

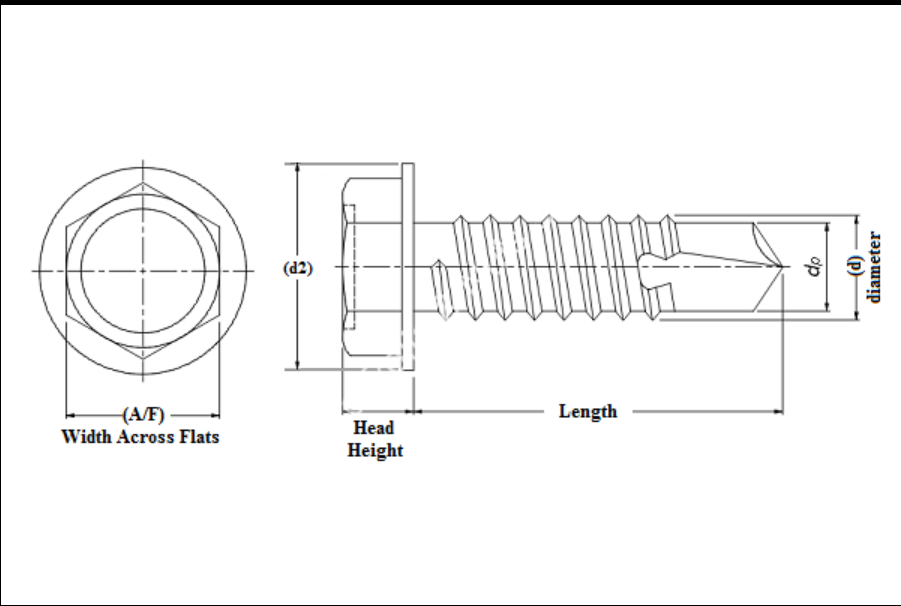

Self-drilling screws, also known as Tek screws, are designed to drill their own hole into a material as they are installed. This unique feature eliminates the need for a pre-drilled hole, which streamlines the assembly process and enhances productivity. Made typically from high-strength steel, these screws often come with a corrosion-resistant coating, making them highly suitable for various metal applications, including roofing, sheet metal assembly, and HVAC installations.

One of the standout features of self-drilling screws is their unique drill point design. The drill point allows the screw to penetrate metal effortlessly, creating a precise fit while avoiding the risk of damaging the surrounding material. This attribute is particularly beneficial in metal factories, where precision and durability are essential for the longevity of structures and components.

Self-drilling screws are categorized into different types based on their application and the metal thickness they can handle. For instance, screws with a lower gauge are ideal for thinner materials, while those with higher gauge numbers are more suited for heavier applications. The variety of head styles, including hex, pan, and flat heads, ensures that there is a self-drilling screw specifically tailored for every need within the factory setting.

self drilling screw for metal factories

The advantages of using self-drilling screws in metal fabrication are numerous. Firstly, the time-saving aspect is significant; with self-drilling capabilities, there is no need to switch between tools or spend extra time on pre-drilling, which can lead to notable reductions in labor costs. Additionally, the strong bond and excellent load-bearing capacities of these screws contribute to the overall safety and durability of structures, making them an ideal choice for critical applications.

Furthermore, self-drilling screws are versatile. They can effectively fasten various metal sheets, including galvalume, aluminum, and stainless steel, lending themselves to a wide array of applications in metal factories. Whether it’s for constructing metal roofs, assembling machinery, or fabricating metal frames, self-drilling screws provide reliable performance across diverse tasks.

In today's competitive manufacturing environment, efficiency and quality go hand-in-hand. The use of self-drilling screws not only enhances operational efficiency but also improves the overall quality of the finished product. As industries strive to adopt more efficient practices, these fasteners are poised to become a standard in metalworking applications.

In conclusion, self-drilling screws represent a significant advancement in the fastener industry, particularly for metal factories. Their ability to eliminate the need for pre-drilling, combined with high strength and versatility, makes them an indispensable tool in modern metal fabrication. As technology continues to evolve, the importance of self-drilling screws will likely increase, reinforcing their role as a cornerstone of reliable and efficient metalworking solutions. Embracing such advancements ensures that manufacturers can meet the ever-increasing demands for high-quality production in a cost-effective manner.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024