Feb . 04, 2025 04:45

Back to list

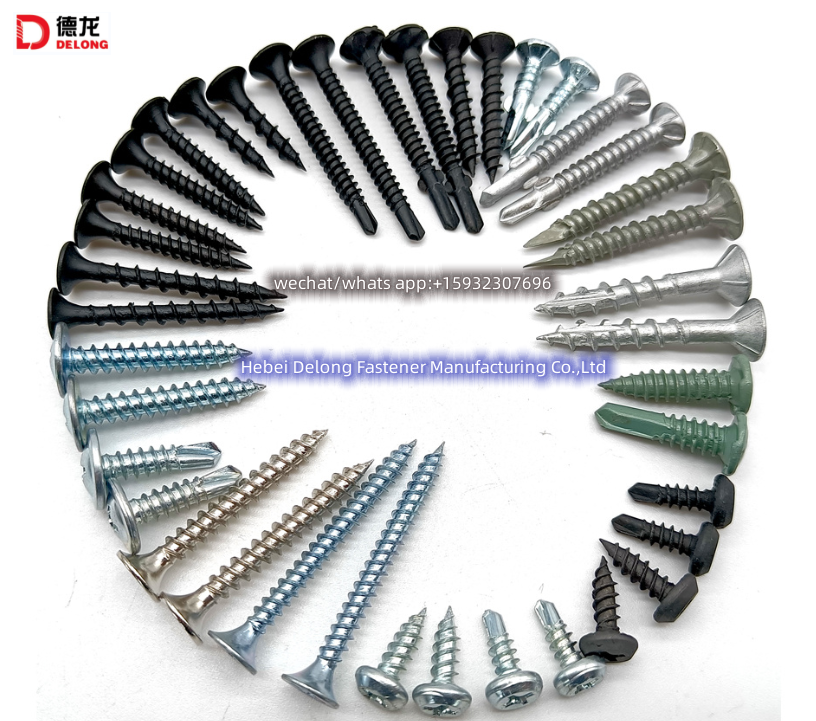

YZP CHIPBOARD SCREW

For every builder and DIY enthusiast, finding reliable and efficient tools and accessories is a mission-critical task. Among these, self-drilling screw caps stand out as a game-changing innovation that enhances the efficacy and aesthetic of construction and assembly projects. With countless applications ranging from home improvement to large-scale industrial projects, understanding the value and proper usage of self-drilling screw caps is crucial for anyone looking to maintain a high standard of construction integrity.

Experts in the field recognize the importance of pairing self-drilling screw caps with suitable washers and gaskets to further augment their sealing capabilities. This combination creates an airtight seal, preventing water ingress, which is crucial in preventing structural wood decay and metal rust. The inclusion of a gasket can act as a cushion, distributing pressure evenly and preventing the screw from backing out over time due to vibration or changing loads. Trustworthiness and reliability are key aspects when choosing suppliers for self-drilling screw caps. Experienced professionals often recommend sourcing from well-established manufacturers known for their stringent quality controls and innovative product lines. Advanced production techniques and material science ensure that these small components meet the rigorous demands of modern construction. For instance, products that comply with international standards such as the ISO certification are generally trusted to deliver durability and performance. A discussion around self-drilling screw caps would be incomplete without considering their evolving role in eco-friendly building practices. Modern manufacturing approaches have enabled the creation of caps using recycled materials, contributing to reduced carbon footprints. When planning a sustainable project, choosing environmentally-friendly components, like these advanced screw caps, underscores a commitment to building responsibly. Overall, incorporating self-drilling screw caps in your construction toolkit not only optimizes the build process through reduced time and costs but also enhances the enduring quality and appearance of your projects. Through careful selection and application, these versatile components can transform how traditional fastening systems are conceptualized and executed. Builders and DIYers alike continue to praise their structural and aesthetic benefits, making them an indispensable asset in innovative construction strategies.

Experts in the field recognize the importance of pairing self-drilling screw caps with suitable washers and gaskets to further augment their sealing capabilities. This combination creates an airtight seal, preventing water ingress, which is crucial in preventing structural wood decay and metal rust. The inclusion of a gasket can act as a cushion, distributing pressure evenly and preventing the screw from backing out over time due to vibration or changing loads. Trustworthiness and reliability are key aspects when choosing suppliers for self-drilling screw caps. Experienced professionals often recommend sourcing from well-established manufacturers known for their stringent quality controls and innovative product lines. Advanced production techniques and material science ensure that these small components meet the rigorous demands of modern construction. For instance, products that comply with international standards such as the ISO certification are generally trusted to deliver durability and performance. A discussion around self-drilling screw caps would be incomplete without considering their evolving role in eco-friendly building practices. Modern manufacturing approaches have enabled the creation of caps using recycled materials, contributing to reduced carbon footprints. When planning a sustainable project, choosing environmentally-friendly components, like these advanced screw caps, underscores a commitment to building responsibly. Overall, incorporating self-drilling screw caps in your construction toolkit not only optimizes the build process through reduced time and costs but also enhances the enduring quality and appearance of your projects. Through careful selection and application, these versatile components can transform how traditional fastening systems are conceptualized and executed. Builders and DIYers alike continue to praise their structural and aesthetic benefits, making them an indispensable asset in innovative construction strategies.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News