Factory for Self-Drilling Pan Head Screws with High Quality and Competitive Pricing

The Evolution and Importance of Self-Drilling Pan Head Screws in Modern Manufacturing

In the world of fasteners, self-drilling screws play a pivotal role, ushering in an era of efficiency, precision, and reliability. Specifically, self-drilling pan head screws have emerged as essential components that cater to various industries, including construction, automotive, aerospace, and furniture manufacturing. Understanding the intricacies of these specialized fasteners requires delving into their design, applications, and the manufacturing processes involved in creating high-quality products.

What Are Self-Drilling Pan Head Screws?

Self-drilling pan head screws are unique fasteners equipped with a drill point that allows them to create their own hole as they are driven into a material. This feature eliminates the need for pre-drilling, which not only saves time but also enhances productivity on the job site or assembly line. The pan head design offers a broader bearing surface, making it ideal for applications requiring a flush finish, such as attaching metal sheets or wooden structures.

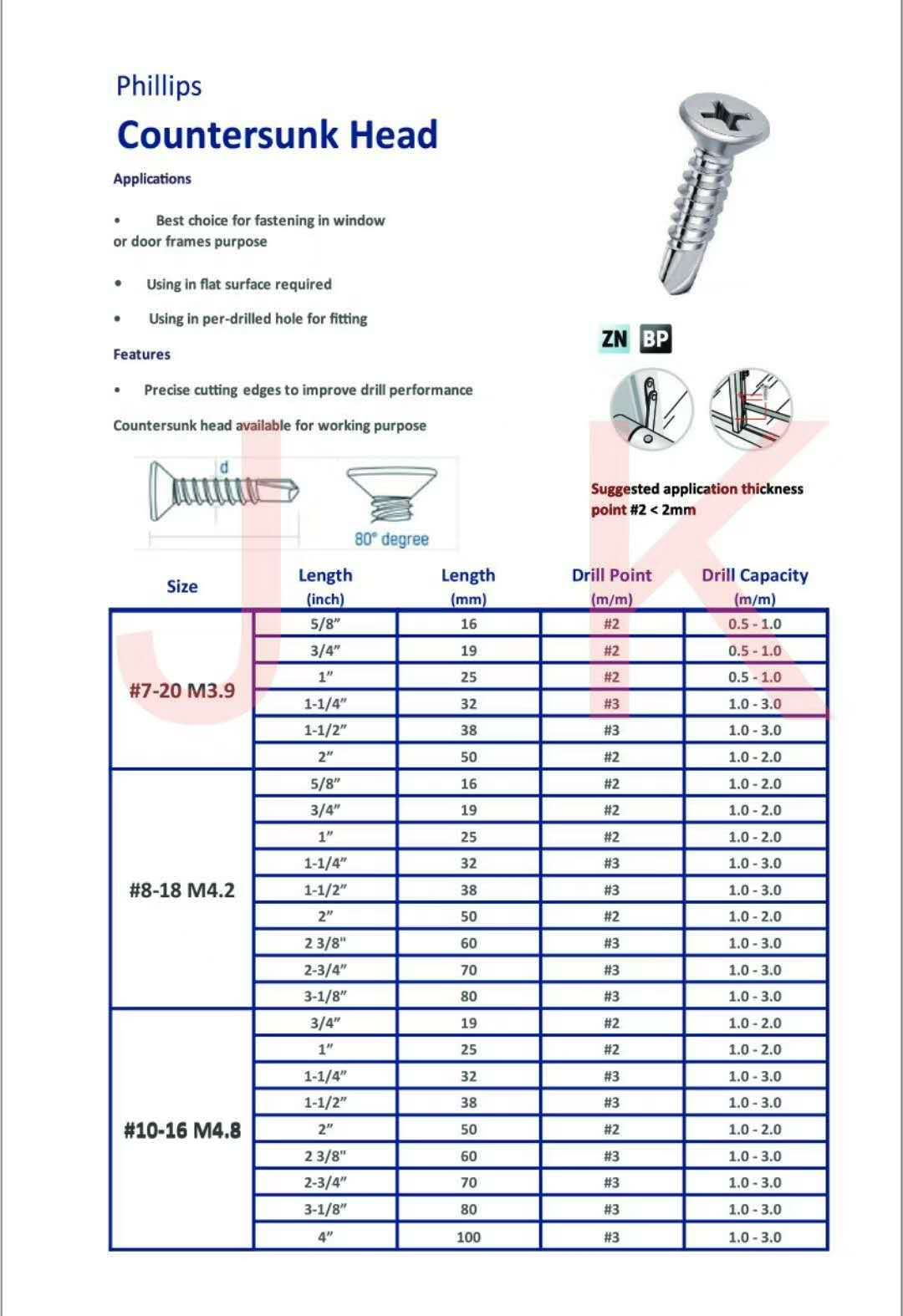

Self-drilling screws come in various sizes and materials, catering to diverse requirements. They are often made from zinc-plated steel for corrosion resistance or stainless steel for applications in harsher environments. The choice of material and coating significantly influences the screw's performance and longevity, making it crucial for manufacturers to select appropriate options based on the intended application.

Advantages of Self-Drilling Pan Head Screws

1. Time Efficiency By eliminating the need for pre-drilled holes, self-drilling screws drastically reduce installation time. This feature is particularly beneficial in large-scale projects where numerous fasteners are required.

2. Reduced Labor Costs The ease of use of self-drilling screws translates to lower labor costs. Workers can focus on other aspects of their tasks without the need for additional drilling tools or processes.

3. Versatile Applications These screws are incredibly versatile, finding applications in various sectors, including construction (for attaching roofing and siding), electronics (for assembling components), and furniture (for joining parts seamlessly).

self drilling pan head screw factory

4. High Strength and Stability Self-drilling pan head screws are designed to provide strong, lasting connections. Their ability to self-tap into materials ensures that they can withstand vibrations and various loads without loosening over time.

5. Enhanced Aesthetics The pan head design provides a cleaner, more finished appearance compared to other screw types, making it an excellent choice for visible applications.

Manufacturing Process of Self-Drilling Pan Head Screws

The production of self-drilling pan head screws is a meticulous process that begins with selecting the right raw materials. Manufacturers typically utilize cold heading technology to shape the screw's head and shaft. This method not only enhances durability but also allows for mass production without compromising quality.

Following the cold heading process, the screws undergo heat treatment to improve their strength and hardness. This step is critical, particularly for screws intended for heavy-duty applications. Once heat-treated, the screws are cut to the desired lengths, and the drill points are formed. This stage requires precision engineering to ensure that the drill points effectively penetrate the intended materials.

Surface finishing is the final step in the manufacturing process. Various coatings, such as zinc plating or powder coating, are applied to increase corrosion resistance and enhance the screw's aesthetic appeal. After quality control checks, the screws are packaged for distribution, ready to meet the demands of various industries.

Conclusion

Self-drilling pan head screws represent a significant advancement in fastening technology, providing an array of benefits that cater to modern manufacturing needs. Their ability to streamline installation processes and improve productivity makes them indispensable in numerous applications. As industries continue to evolve, the demand for high-quality, efficient fastening solutions like self-drilling pan head screws will undoubtedly grow.

With continuous innovations in material science and manufacturing techniques, the future of self-drilling screws looks promising. Manufacturers that prioritize quality, efficiency, and customer needs will play a crucial role in shaping the industry landscape, ensuring that self-drilling pan head screws remain a preferred choice in construction and assembly projects worldwide. Whether you are a builder, manufacturer, or DIY enthusiast, understanding and utilizing these fasteners can lead to better results and enhanced productivity.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024