Jun . 20, 2024 01:13

Back to list

Self-tapping screw sizes and applications.

Navigating the World of Self-Tapping and Self-Drilling Screws A Guide to Size Charts and Product Selection

When it comes to fastening materials, self-tapping and self-drilling screws are invaluable tools that offer convenience and efficiency. These specialized screws eliminate the need for pre-drilling holes, saving time and effort during installation. However, with a myriad of sizes and types available, selecting the right screw for your project can be daunting. This article aims to demystify the process by providing an overview of self-tapping and self-drilling screw size charts and offering tips on product selection.

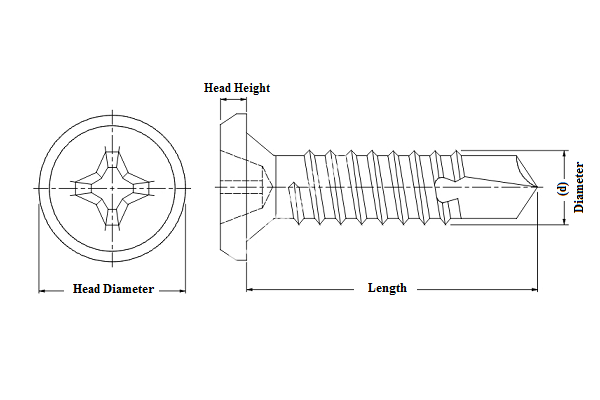

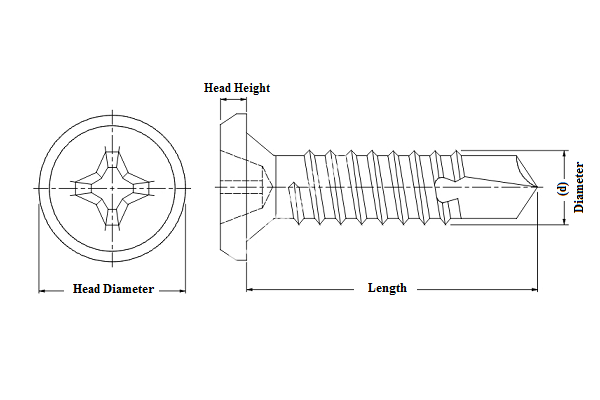

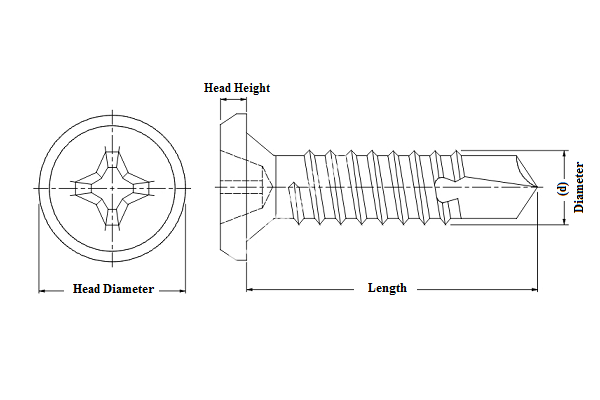

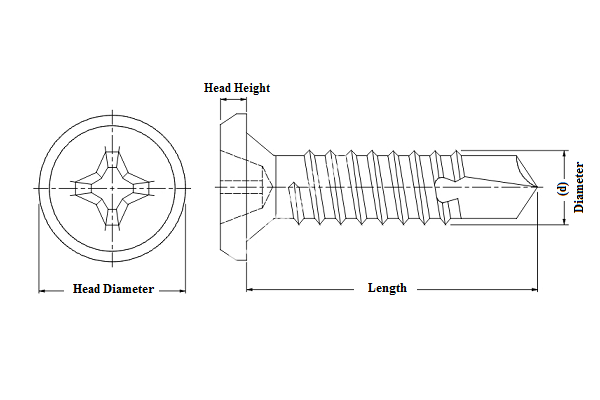

Self-tapping screws are designed to tap their own thread into soft materials such as wood or plastic as they are driven in. They have a drill-like tip that allows them to penetrate the surface without the need for a pilot hole. On the other hand, self-drilling screws are equipped with a drill bit-like tip that actually drills through the material before the threads set. Both types come in various sizes, denoted by diameter and length, which are crucial for ensuring optimal performance and load-bearing capacity.

To choose the correct size, one must consult a size chart specific to the screw type being used. These charts list the dimensions of the screws, including the diameter of the shank and the length of the screw from underhead to point. It's essential to match the screw size with the thickness of the materials being joined to prevent protrusion or inadequate engagement.

When selecting products, consider the following factors

1. Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening

Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening self tapping self drilling screw size chart products.

2. Material Type Choose between self-tapping for softer materials and self-drilling for harder ones, like metal or masonry.

3. Corrosion Resistance For outdoor projects or damp environments, opt for stainless steel or other corrosion-resistant materials.

4. Head Style The screw head should match the tool you'll use; for example, a hex head for an allen wrench or Phillips for a Phillips driver.

5. Torque Requirements Some jobs may require more torque than others; select screws that can handle the expected load.

In conclusion, understanding the differences between self-tapping and self-drilling screws, referencing accurate size charts, and considering project-specific requirements are key steps in choosing the right fasteners for your task. With the right knowledge and preparation, you can ensure that your build is strong, secure, and efficient. Remember, the right tool for the job not only saves time but also ensures a professional finish that stands the test of time.

self tapping self drilling screw size chart products.

2. Material Type Choose between self-tapping for softer materials and self-drilling for harder ones, like metal or masonry.

3. Corrosion Resistance For outdoor projects or damp environments, opt for stainless steel or other corrosion-resistant materials.

4. Head Style The screw head should match the tool you'll use; for example, a hex head for an allen wrench or Phillips for a Phillips driver.

5. Torque Requirements Some jobs may require more torque than others; select screws that can handle the expected load.

In conclusion, understanding the differences between self-tapping and self-drilling screws, referencing accurate size charts, and considering project-specific requirements are key steps in choosing the right fasteners for your task. With the right knowledge and preparation, you can ensure that your build is strong, secure, and efficient. Remember, the right tool for the job not only saves time but also ensures a professional finish that stands the test of time.

Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening

Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening Material Thickness Ensure that the screw is long enough to penetrate through the materials and leave enough thread exposed for proper tightening self tapping self drilling screw size chart products.

2. Material Type Choose between self-tapping for softer materials and self-drilling for harder ones, like metal or masonry.

3. Corrosion Resistance For outdoor projects or damp environments, opt for stainless steel or other corrosion-resistant materials.

4. Head Style The screw head should match the tool you'll use; for example, a hex head for an allen wrench or Phillips for a Phillips driver.

5. Torque Requirements Some jobs may require more torque than others; select screws that can handle the expected load.

In conclusion, understanding the differences between self-tapping and self-drilling screws, referencing accurate size charts, and considering project-specific requirements are key steps in choosing the right fasteners for your task. With the right knowledge and preparation, you can ensure that your build is strong, secure, and efficient. Remember, the right tool for the job not only saves time but also ensures a professional finish that stands the test of time.

self tapping self drilling screw size chart products.

2. Material Type Choose between self-tapping for softer materials and self-drilling for harder ones, like metal or masonry.

3. Corrosion Resistance For outdoor projects or damp environments, opt for stainless steel or other corrosion-resistant materials.

4. Head Style The screw head should match the tool you'll use; for example, a hex head for an allen wrench or Phillips for a Phillips driver.

5. Torque Requirements Some jobs may require more torque than others; select screws that can handle the expected load.

In conclusion, understanding the differences between self-tapping and self-drilling screws, referencing accurate size charts, and considering project-specific requirements are key steps in choosing the right fasteners for your task. With the right knowledge and preparation, you can ensure that your build is strong, secure, and efficient. Remember, the right tool for the job not only saves time but also ensures a professional finish that stands the test of time. Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News