self tapping screw m4 service

Understanding Self-Tapping Screws Focus on M4 Service

Self-tapping screws have become a vital component in modern manufacturing and construction, providing a reliable fastening solution across various applications. Among the many types available, the M4 self-tapping screw stands out due to its versatility and efficiency. This article explores the characteristics, advantages, and service applications of M4 self-tapping screws.

What is a Self-Tapping Screw?

A self-tapping screw is a fastener designed to create its own thread in material as it is driven in. Instead of requiring a pre-drilled hole, these screws can be used on materials like metal, plastic, and wood, making them an excellent choice for quick assembly and disassembly tasks. The design typically includes a sharp point and aggressive thread patterns that allow for easy penetration and secure fastening.

Characteristics of M4 Self-Tapping Screws

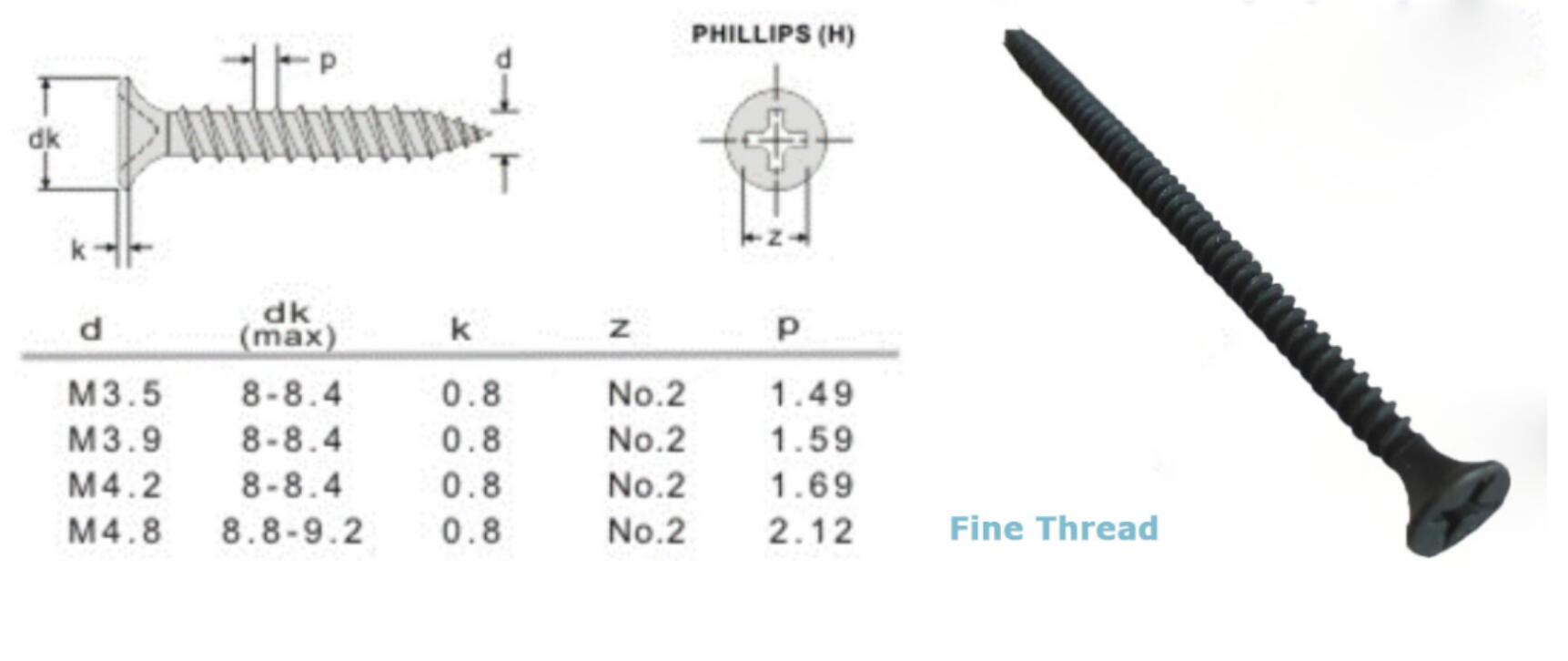

The term M4 refers to the diameter of the screw, which is 4 mm. This size is particularly popular in applications where a balance is needed between strength and weight. M4 screws often feature various thread types, such as coarse or fine, suitable for different materials and tension requirements. They can be manufactured from a range of materials, including stainless steel, carbon steel, and plastic, which enhances their resistance to corrosion and wear.

self tapping screw m4 service

Advantages of M4 Self-Tapping Screws

One of the most notable benefits of using M4 self-tapping screws is their efficiency in installation. They eliminate the need for separate drilling operations, significantly reducing assembly time and labor costs. Additionally, the ability to tap threads directly into the materials means that these screws can be removed and reused without compromising their holding power. This feature is crucial in sectors requiring regular maintenance or adjustments, such as in automotive and electronics.

Applications of M4 Self-Tapping Screws

M4 self-tapping screws find applications in various industries, including manufacturing, construction, and electronics. In the automotive sector, they are often used for securing body panels and interior components. In electronics, M4 screws serve to secure circuit boards and housings, ensuring that sensitive components remain properly aligned. In construction, these screws are advantageous for attaching metal frames, fixtures, and panels, providing a sturdy solution that withstands stress and vibration.

Conclusion

In conclusion, M4 self-tapping screws offer a versatile and efficient fastening solution across multiple applications. Their unique ability to create threads as they are driven into a material saves time and enhances productivity, making them a preferred choice in many industries. Understanding their characteristics and appropriate use can significantly improve assembly processes and overall project outcomes. Whether for industrial manufacturing or DIY projects, M4 self-tapping screws are invaluable tools that deserve consideration.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024