self tapping screw dwg quotes

Understanding Self-Tapping Screws A Comprehensive Overview

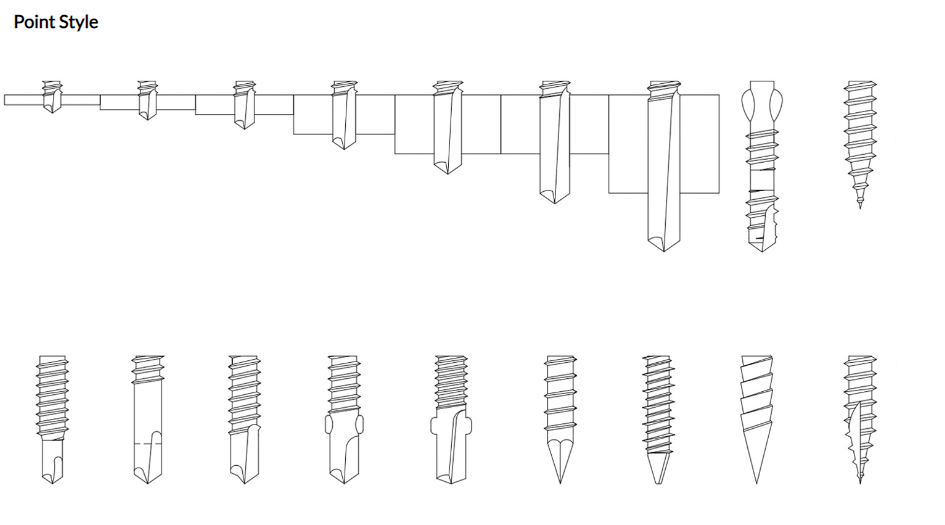

Self-tapping screws are essential fasteners in various applications ranging from construction to electronics. Unlike conventional screws that require a pre-drilled hole, self-tapping screws create their own thread as they are driven into the material. This feature not only saves time during installation but also enhances the overall strength and reliability of the connection.

Understanding Self-Tapping Screws A Comprehensive Overview

When specifying self-tapping screws, it's important to consider various factors, such as material, coating, and thread type. Materials can range from stainless steel to carbon steel, each offering different levels of corrosion resistance and strength. Coatings, such as zinc plating, provide additional protection against environmental factors, which is crucial in outdoor or humid applications.

self tapping screw dwg quotes

Self-tapping screws are available in two main types Thread-forming and Thread-cutting. Thread-forming screws displace material to create threads without removing any substrate, making them ideal for softer materials like plastic. Conversely, thread-cutting screws are more suited for harder materials, as they remove material to form threads, thus ensuring a secure fit.

Another important consideration is the screw drive type, which determines how the screw is installed. Common drive types include Phillips, slotted, and Torx. Each drive type has distinct advantages, with Torx providing better torque and reducing the likelihood of cam-out during installation.

In terms of applications, self-tapping screws are widely used in the automotive industry, HVAC systems, and home repairs. Their versatility allows them to be used in a variety of settings, including assembling furniture, fabricating metal structures, and installing electronic components.

In summary, self-tapping screws are vital fasteners that enhance the efficiency and strength of various applications. By understanding their characteristics and the appropriate selection based on material and design, users can ensure optimal performance in their projects. Whether you're involved in industrial manufacturing or DIY home improvement, self-tapping screws are an invaluable component deserving of attention in any fastening scenario.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024