self tapping screw clips suppliers

Exploring the World of Self-Tapping Screw Clips Suppliers

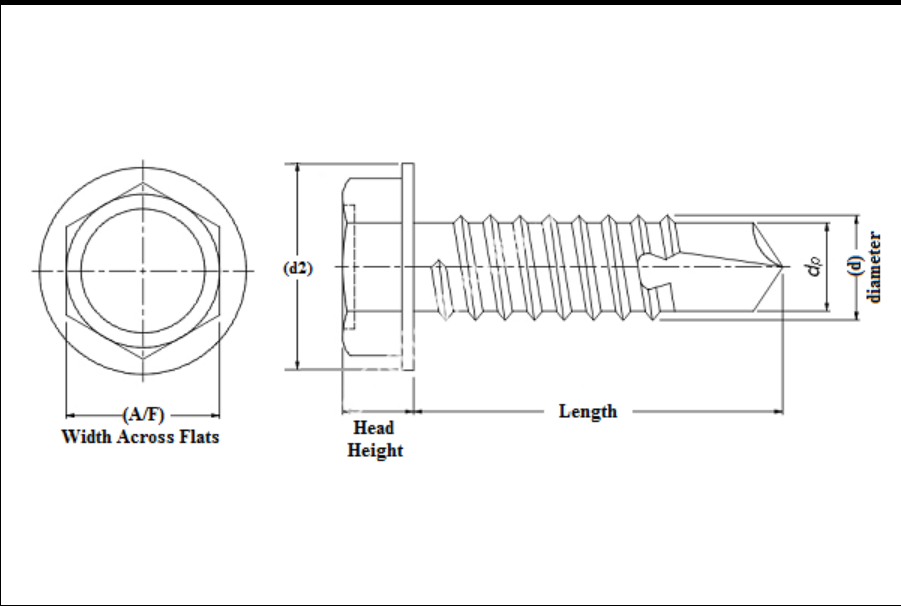

In the ever-evolving landscape of manufacturing and construction, self-tapping screws play a pivotal role in fastening and securing components. These innovative fasteners are designed to create their own holes in various materials, eliminating the need for pre-drilled holes. This efficiency has led to increased demand for self-tapping screws and their accompanying accessories, such as screw clips. As a result, the market has witnessed a surge in suppliers offering high-quality self-tapping screw clips suited for a diverse range of applications.

Understanding Self-Tapping Screws and Their Necessity

Self-tapping screws are particularly appreciated in industries where speed and reliability are paramount. They work effectively with materials like metal, wood, and plastic, providing a tight grip without the risk of loosening over time. This characteristic makes them ideal for use in automotive, construction, and electronic applications, where secure fastening is crucial for safety and functionality.

Self-tapping screw clips are essential accessories that enhance the application of these screws. Clips ensure that the screw remains in place, offering additional support and stability to the assembly. They are designed to hold screws securely, making them easier to handle during installation and reducing the risk of damage to the materials being fastened.

The Role of Suppliers in the Market

The market for self-tapping screw clips suppliers has evolved, offering a variety of choices for manufacturers and builders. Suppliers are not just limited to traditional hardware stores; many specialized distributors focus solely on fasteners and related components. These suppliers provide expertise and a range of products that cater to specific industry needs.

self tapping screw clips suppliers

When selecting a supplier, it is vital to consider several factors, including product quality, range of offerings, pricing, and customer support. Established suppliers often carry a variety of sizes and types of screw clips, ensuring that customers can find the exact specifications they need for their projects. Furthermore, many suppliers offer custom solutions, enabling businesses to order designs tailored to their specific applications.

Quality and Innovation in Fasteners

With the rise of technology and advanced manufacturing processes, many suppliers are incorporating innovations into their products. For instance, the use of high-grade materials enhances the durability and corrosion resistance of screw clips, ensuring they perform well in harsh environments. Innovations such as coatings that reduce friction and improve gripping capabilities are also becoming more common, making these fasteners even more reliable.

Quality assurance is another critical aspect of the supply chain. Reputable suppliers often provide certifications and testing results to demonstrate the reliability of their products. This transparency not only builds trust with customers but also ensures that the fasteners meet industry standards and regulations.

Conclusion

The demand for self-tapping screw clips is a testament to the growing complexity and sophistication of modern manufacturing and construction. Suppliers play a crucial role in this ecosystem, providing the necessary components that enhance the efficiency and safety of diverse applications. As industries continue to evolve, the partnership between manufacturers and suppliers will be vital in driving advancements in fastening technology. Companies that prioritize choosing reliable suppliers will benefit from improved productivity, reduced costs, and better overall performance in their projects. The fastener industry is indeed on the rise, and staying informed about suppliers and innovations is key to success in this competitive field.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024