screw with spring washer suppliers

The Importance of Screw with Spring Washer Suppliers

When it comes to mechanical engineering and construction, the significance of reliable components cannot be overstressed. One such component, often overlooked yet crucial, is the screw with a spring washer. This combination is essential for ensuring the stability and durability of mechanical assemblies. The role of suppliers in providing high-quality screws with spring washers cannot be understated, as they contribute to the effectiveness and safety of various applications.

Understanding Screws and Spring Washers

Before delving into the role of suppliers, it’s important to understand what screws and spring washers are. A screw is a fastener that consists of a cylindrical body with a helical ridge or thread wrapped around it. These fasteners are used to hold objects together by creating internal friction. On the other hand, a spring washer is a type of washer that is designed to exert a constant pressure on a screw or bolt, helping to maintain the assembly's tightness and stability.

When these two components are used together, they offer several advantages. For example, the spring washer prevents loosening due to vibrations or thermal expansion, thereby enhancing the durability of the assembly. This makes screws with spring washers particularly useful in applications such as automotive parts, machinery, and structural engineering projects.

The Role of Suppliers

screw with spring washer suppliers

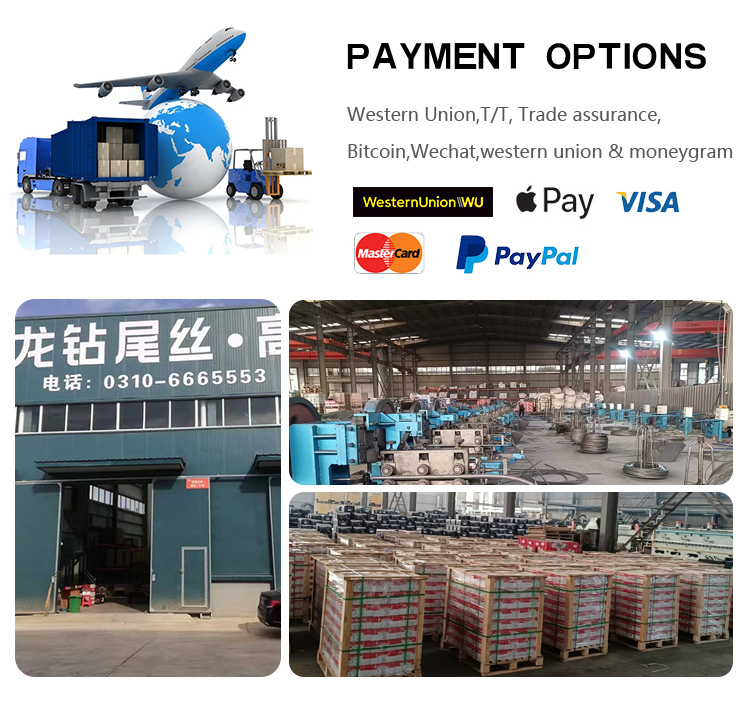

Screw with spring washer suppliers play a pivotal role in the supply chain, ensuring that manufacturers have access to high-quality fasteners that meet industry standards. A reliable supplier not only sources screws and washers from reputable manufacturers but often provides additional services such as custom packaging, bulk purchasing options, and technical support.

One of the key factors to consider when choosing a supplier is the quality of their products. The screws and washers must be made from durable materials that can withstand environmental stresses, such as corrosion, heat, and pressure. Suppliers that comply with international standards, such as ISO or ASTM, offer greater assurance regarding the quality and reliability of their products.

Another vital aspect is the supplier's ability to provide a diverse range of products. Different applications require different types of screws and washers, so suppliers that can offer various sizes, materials, and coatings are invaluable. This diversity allows manufacturers to find the exact components they need for specific projects without having to compromise on quality.

Conclusion

In summary, the importance of screws with spring washers in various mechanical applications cannot be overstated. These components play a crucial role in ensuring that assemblies remain secure and stable over time. The suppliers of these products are essential partners in the manufacturing process, providing the necessary quality and diversity to meet industry demands. As industries continue to evolve, the role of screw with spring washer suppliers will remain critical in ensuring that high standards of safety and reliability are maintained in mechanical engineering and construction projects. Choosing the right supplier can significantly impact the overall success of projects, making it imperative to conduct thorough research and select a trusted partner in this field.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024