screw pattern for fire rated drywall exporters

Exploring Screw Patterns for Fire-Rated Drywall Insights for Exporters

The importance of fire-rated drywall in construction cannot be overstated. As safety regulations become increasingly stringent, the demand for high-quality fire-rated drywall products is expanding globally. Among the many considerations for ensuring the integrity and performance of fire-rated drywall is the proper application of screw patterns during installation. For exporters of fire-rated drywall, understanding these patterns is crucial to meet industry standards and client expectations.

The Role of Fire-Rated Drywall

Fire-rated drywall, often referred to as Type X drywall, is designed to resist fire and limit the spread of flames, smoke, and heat. It is commonly used in commercial buildings, residential complexes, and anywhere that requires compliance with fire safety codes. Fire-rated drywall typically contains additives that enhance its fire-resistance properties, making it vital for partitions, ceilings, and other structural applications.

Importance of Proper Screw Patterns

The installation of fire-rated drywall is not just about hanging sheets; it's about ensuring that they are securely fastened to maintain their fire-resistant properties. The screw pattern plays a critical role in this process. An incorrect pattern can compromise the integrity of the wall assembly, resulting in potential failure during a fire.

Generally, the recommended screw pattern involves placing screws at specified intervals along the edges and fields of the drywall sheets. For instance, it’s common practice to place screws every 16 inches along the edges and every 24 inches in the field (the center area of the drywall sheet). This pattern helps distribute the load evenly and prevents sagging or separation of the drywall from the framing structure.

Factors Influencing Screw Patterns

Several factors influence the choice of screw patterns for fire-rated drywall.

1. Type of Structure The overall design of the building plays a significant role in determining the appropriate screw pattern. Different structural elements, such as drywall thickness and framing type, require tailored approaches.

2. Building Codes Adherence to local building codes is essential. These codes dictate specific screw patterns, spacing, and additional fire-rated assembly requirements.

screw pattern for fire rated drywall exporters

3. Type of Fire-Rated Drywall Different fire-rated drywall products may have different installation requirements. Manufacturers often provide guidelines that must be followed to maintain the product's fire-resistance ratings.

4. Environmental Conditions The installation environment also influences screw patterns. For example, drywall installed in high-moisture areas may require additional fasteners to mitigate the effects of humidity and potential mold growth.

Recommendations for Exporters

For exporters of fire-rated drywall, understanding the nuances of screw patterns not only enhances product knowledge but also strengthens customer relationships. Here are some recommendations for working with international markets

1. Educate Clients Provide resources and training materials that explain the importance of proper screw patterns. This can help contractors and installers understand the significance of adherence to guidelines.

2. Offer Samples and Demonstrations Consider providing samples along with installation demonstrations to showcase the proper screw patterns. This practical approach can facilitate better understanding and compliance.

3. Stay Updated on Regulations Regulatory standards can vary from one country to another. Exporters should stay informed about local fire safety codes and recommend screw patterns that comply with these regulations.

4. Build Partnerships Collaborate with local contractors and builders to ensure that your products are installed correctly. This not only enhances safety but also promotes customer satisfaction and loyalty.

Conclusion

In the competitive landscape of fire-rated drywall export, understanding the intricacies of screw patterns can set a company apart. By prioritizing proper installation techniques and educating clients, exporters can play a pivotal role in ensuring safety and compliance in construction projects worldwide. As building safety remains a paramount concern, solidifying knowledge in this area will not only promote reliable products but also contribute to a safer built environment.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

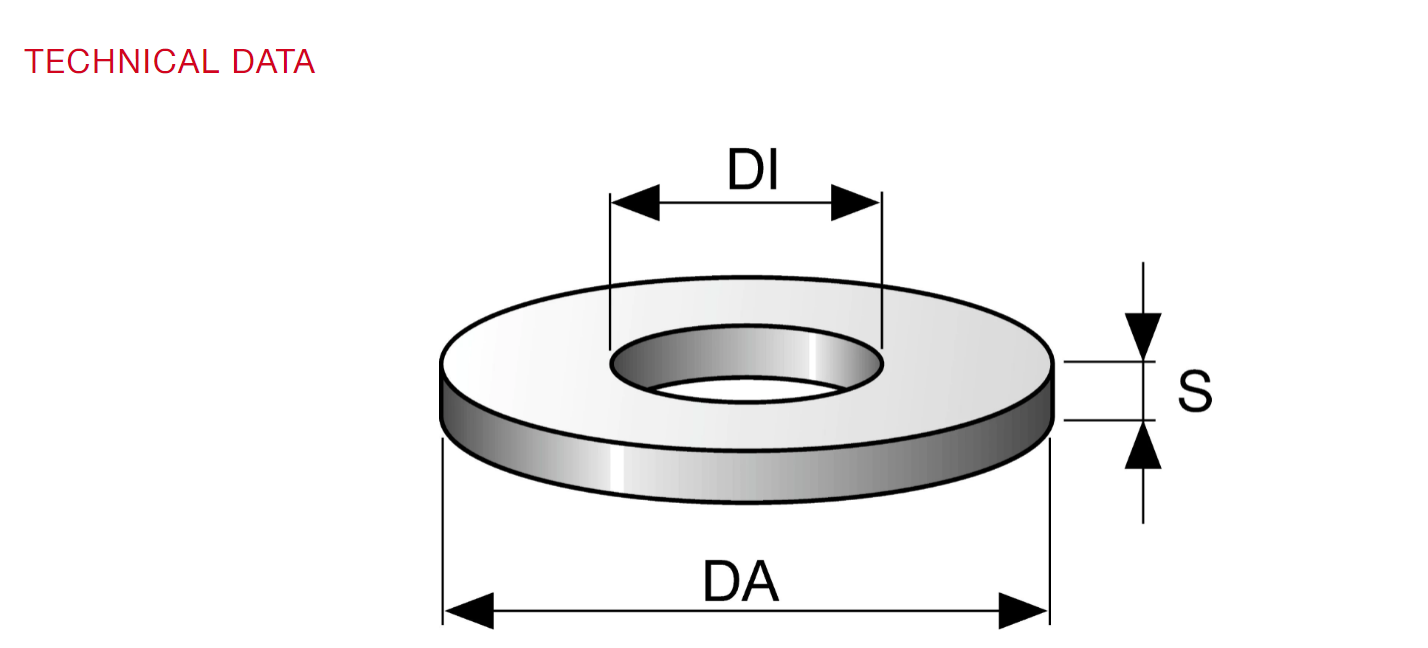

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024