screw self tapping service

Screw Self-Tapping Service Enhancing Efficiency and Quality in Construction

In the realm of construction and manufacturing, the importance of quality and efficiency cannot be overstated. Among the numerous components that play a vital role in these industries, self-tapping screws have emerged as a practical solution for various fastening needs. The screw self-tapping service offers a unique advantage, allowing for seamless integration of materials while maintaining structural integrity and durability.

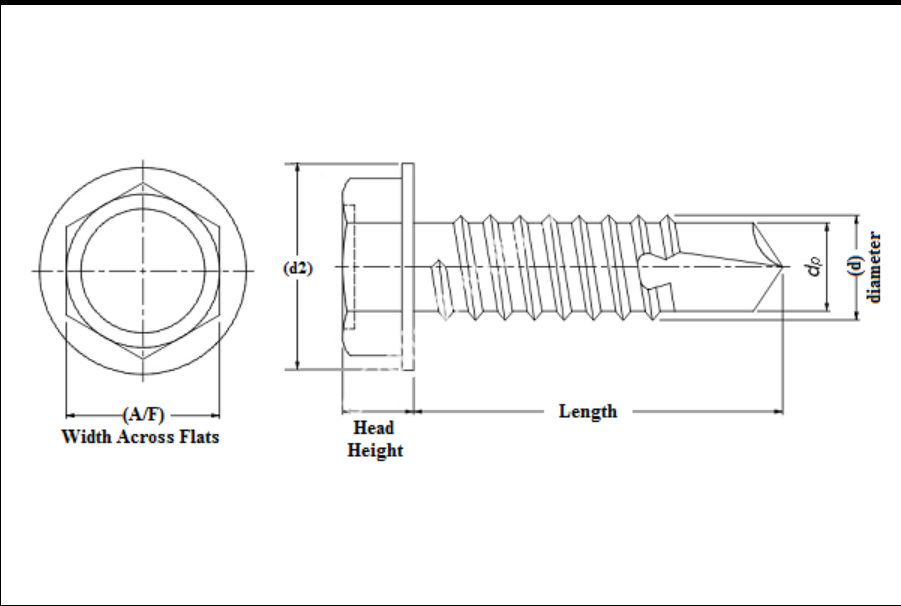

Self-tapping screws are designed with a unique thread construction that allows them to create their own mating thread in the material they are driven into. This eliminates the need for pre-drilled holes, saving time and reducing labor costs. The broad applicability of self-tapping screws, from metal and plastic to wood, has made them a preferred choice in many projects, ranging from simple furniture assembly to complex industrial applications.

Screw Self-Tapping Service Enhancing Efficiency and Quality in Construction

Another critical aspect of using a screw self-tapping service is the consistency in product quality. Reputable suppliers adhere to strict manufacturing standards, ensuring that each batch of screws meets certain specifications. This reliability is crucial for maintaining the integrity of structures and products. High-quality self-tapping screws are engineered to withstand various environmental conditions, from extreme temperatures to exposure to moisture, thereby prolonging the lifespan of the finished product.

screw self tapping service

Moreover, screw self-tapping services often provide additional benefits, such as customization options and technical support. Suppliers can assist clients in selecting the appropriate screw type, material, and coating based on the specific demands of their projects. This guidance is invaluable, particularly for new entrants in the construction industry or those venturing into specialized fields requiring unique fastening solutions.

The ease of sourcing self-tapping screws through dedicated services also encourages innovation. As manufacturers seek to incorporate new materials and techniques into their projects, the adaptability of self-tapping screws supports a wide range of applications. From automotive assembly lines to residential construction, the versatility of these fasteners allows for enhanced design flexibility and creativity.

In addition to the technical advantages, the economic benefits of using a self-tapping screw service are significant. Reduced labor costs, faster assembly times, and fewer materials wasted during the fastening process contribute to lower operational costs. This economic efficiency can be a game-changer in competitive industries where margins are tight, enabling companies to offer better pricing or invest in other areas of their business.

In conclusion, the screw self-tapping service plays a vital role in modern construction and manufacturing processes. By providing high-quality, efficient, and customizable fastening solutions, it enhances productivity while ensuring the durability and strength of assemblies. As industries continue to evolve, the reliance on self-tapping screws and their dedicated services will undoubtedly grow, driving innovation and excellence in construction and beyond.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024