Screw Patterns for Drywall Ceiling Installation in China

Understanding the China Screw Pattern for Drywall Ceiling Installation

When it comes to interior construction and remodeling, the installation of drywall ceilings is a common practice that offers aesthetic appeal and functional benefits. Among various techniques and methods employed in drywall installation, the China screw pattern stands out as a preferred choice, especially for those working with lightweight drywall panels. This article explores the principles behind the China screw pattern, its application, benefits, and considerations for effective installation.

The Fundamentals of the China Screw Pattern

The China screw pattern is an installation technique that primarily deals with how screws are applied to the drywall panels when they are affixed to the ceiling framework. This method is characterized by its specific spacing and arrangement of screws, which not only secures the drywall but also helps in distributing weight evenly across the ceiling. Typically, screws are installed along the edges and in the field (the central area) of the drywall sheets in a systematic pattern.

The term China screw draws from the manufacturing standards often associated with drywall materials produced in China. These materials are designed with specific requirements in mind, including lighter weight and compatibility with various screw types. Understanding these requirements is crucial for achieving optimal results during installation.

Benefits of the China Screw Pattern

1. Enhanced Stability One of the key advantages of the China screw pattern is its ability to enhance the overall stability of the drywall ceiling. The strategic placement of screws minimizes the risk of sagging or bowing over time, particularly in larger spans where the drywall is more susceptible to weight distribution issues.

2. Reduction of Fastening Errors The systematic approach of the China screw pattern reduces the likelihood of errors that can occur during fastening. When screws are evenly spaced and correctly aligned, it leads to a more uniform finish, which is critical for painting or applying additional decorative finishes.

3. Improved Structural Integrity By optimizing screw placement, the China screw pattern helps in maintaining the structural integrity of the ceiling, especially under varying temperature conditions that can lead to expansion and contraction of materials.

china screw pattern for drywall ceiling

4. Cost-Efficiency Since this method allows for effective use of resources, it can lead to cost savings in both materials and labor. By preventing issues such as sagging or cracking, builders and contractors can avoid the expenses associated with repairs or replacements later on.

Installation Considerations

While the China screw pattern offers several advantages, achieving a perfect installation requires attention to detail. Here are some key considerations

- Screw Type It is essential to choose the right type of screws for drywall installation. Typically, self-tapping screws or drywall screws are recommended, as they are designed to penetrate drywall efficiently without causing damage.

- Spacing Guidelines Following established spacing guidelines is crucial. Generally, screws should be placed 12 to 16 inches apart along the edges and in the field to ensure stability and prevent flexing.

- Proper Tools Having the right tools—such as a drywall screw gun or drill—will facilitate a smoother installation process. An automatic drywall screw gun can adjust the depth of the screw automatically, preventing over-driving and damage to the drywall.

- Ceiling Support Adequate support from furring strips or joists is essential for a successful installation. If the ceiling is unsupported or improperly framed, even the best screw pattern cannot compensate for structural weaknesses.

Conclusion

The China screw pattern has become a prominent method in drywall ceiling installation due to its effectiveness and reliability. By understanding its principles and benefits, construction professionals and DIY enthusiasts can achieve stunning and durable results in their projects. As with any construction technique, attention to detail and adhering to best practices will ensure a finish that is not only visually appealing but also structurally sound. As the industry continues to evolve, techniques like the China screw pattern remain vital in setting standards for quality in drywall installations.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

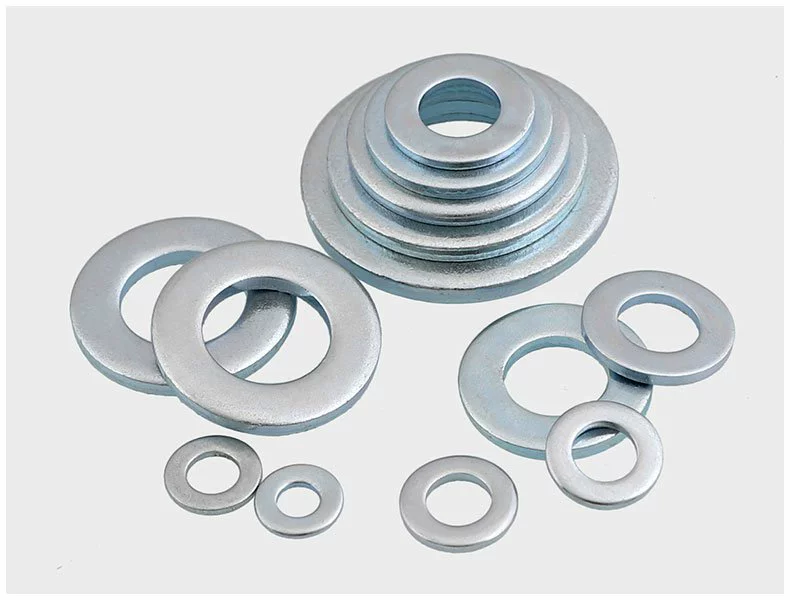

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024