Reliable Suppliers for M8 Self Tapping Screws with High Quality and Competitive Pricing

Understanding M8 Self-Tapping Screws The Essential Components and Supplier Considerations

In the world of construction and manufacturing, screws play a pivotal role in ensuring the integrity and durability of assembled products. Among the various types of screws, the M8 self-tapping screw stands out for its versatility and reliability. This article will delve into the characteristics of M8 self-tapping screws and offer insights for those looking to procure them from suppliers.

What Are M8 Self-Tapping Screws?

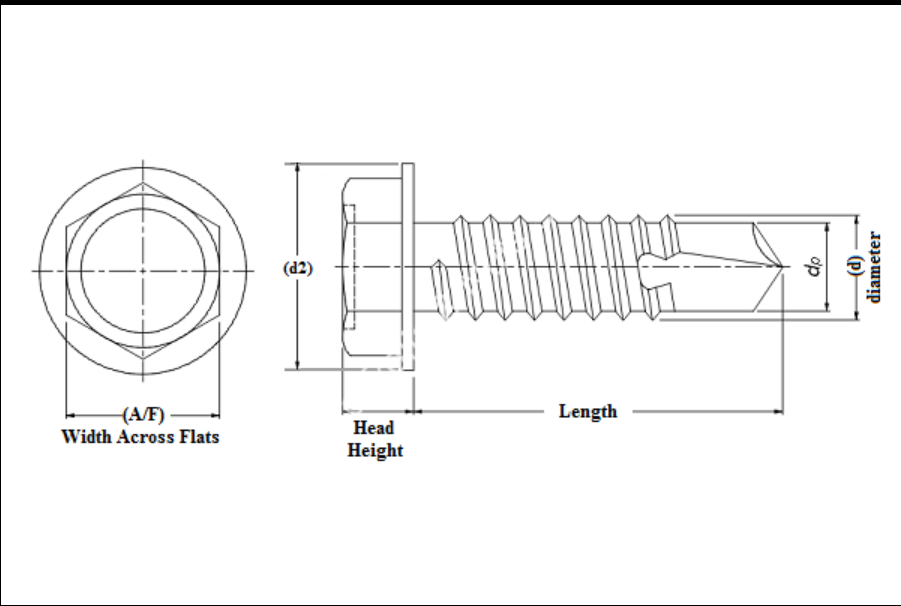

M8 self-tapping screws are a specific type of screw designed to create their own thread in a pre-drilled hole. The M denotes the metric thread, and the 8 indicates a nominal diameter of 8 millimeters. These screws are engineered with sharp, cutting edges that allow them to cut into materials such as metal, plastic, and wood, which eliminates the need for a pre-threaded hole or additional fasteners.

Self-tapping screws are available in various head styles, including flat head, pan head, and hex head, which makes them suitable for a multitude of applications. The choice of head style often depends on the requirements of the project, such as aesthetic considerations and the torque resistance needed to secure the assembly.

Advantages of Using M8 Self-Tapping Screws

1. Efficiency One of the primary benefits of M8 self-tapping screws is their ability to simplify assembly processes. By eliminating the need for additional nuts or washers, they reduce the number of components required, ultimately saving time and labor costs.

2. Cost-Effective With fewer parts and reduced assembly time, M8 self-tapping screws can help companies lower production costs. Their robustness also means that they frequently provide excellent service life, reducing the need for maintenance and replacements.

3. Versatility These screws can be utilized in a wide array of materials, including plastics, soft metals, and wood. This versatility makes M8 self-tapping screws a preferred choice in different industries, from automotive to construction and electronics.

4. Strong Hold The unique design of self-tapping screws allows them to create threads in the material itself, which often results in a stronger hold compared to other types of screws that simply thread into pre-existing holes.

m8 self tapping screw supplier

Choosing the Right Supplier

When sourcing M8 self-tapping screws, it is crucial to select a reputable supplier that can meet your quality and quantity requirements. Here are factors to consider

1. Quality Assurance Look for suppliers who adhere to international quality standards. Certifications such as ISO 9001 can indicate a commitment to quality management systems, ensuring that products meet stringent quality requirements.

2. Material Options M8 self-tapping screws can be made from various materials such as stainless steel, carbon steel, and plastic. Depending on your specific needs, inquire about the available materials and their properties.

3. Customization Some projects may require specific dimensions or coatings, such as corrosion resistance. A good supplier should offer customization options to cater to your unique project specifications.

4. Reputation and Experience Review testimonials and case studies from previous clients to gauge the supplier’s reliability and customer service. An experienced supplier is more likely to understand industry challenges and provide informed solutions.

5. Pricing and Minimum Order Quantities Request quotes from various suppliers to compare pricing. Additionally, consider their minimum order quantities to ensure they align with your project's scale.

Conclusion

M8 self-tapping screws are an essential component in various applications, offering efficiency, versatility, and a strong hold. When searching for a supplier, it is important to consider quality, material options, and customization capabilities. By carefully selecting a reliable supplier, businesses can ensure that they are investing in quality products that will support their manufacturing and construction efforts effectively.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024