Purchase Self-Drilling Screw Drill Bits for Efficient and Precise Home Improvement Projects Online

A Comprehensive Guide to Buying Drill Bits for Self-Drilling Screws

When it comes to DIY projects or professional construction, having the right tools can make a significant difference in efficiency and effectiveness. One essential tool that often gets overlooked is the drill bit, especially when dealing with self-drilling screws. In this article, we will explore the importance of selecting the right drill bit for self-drilling screws and provide guidance on what to consider when making your purchase.

Understanding Self-Drilling Screws

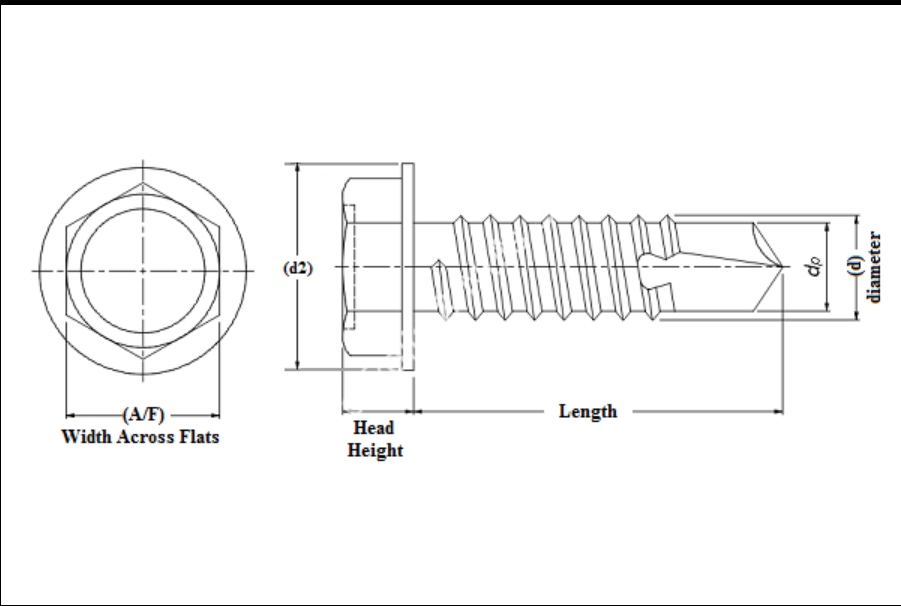

Self-drilling screws, also known as tek screws, are designed to drill their own pilot holes as they are driven into materials, which eliminates the need for separate drilling operations. This feature not only saves time but also enhances the integrity of the installation. However, using the wrong drill bit can compromise the performance of these screws, leading to stripped screw heads, damaged materials, or less-than-ideal fastening.

Key Considerations When Buying Drill Bits

1. Material Compatibility One of the first factors to consider is the material you will be working with. Different materials, such as wood, metal, and plastic, require specific types of drill bits. For instance, high-speed steel (HSS) bits are ideal for metal, while wood bits often feature a pointed tip to help in starting the drill.

2. Bit Size The size of the drill bit is crucial in ensuring the self-drilling screw can achieve the desired depth and hold. You should choose a drill bit that matches the diameter of the screws you're using. Referencing the manufacturer’s specifications will ensure that you select the optimal size.

3. Point Style Drill bits come in various point styles, which can affect how well they perform with self-drilling screws. Some drills feature a split point design that allows for quicker penetration and reduces walking. This is particularly beneficial when working on harder surfaces.

buy drill bit for self drilling screw

4. Coating and Durability Drill bits are often coated with materials like titanium or black oxide to enhance their durability and reduce friction. When selecting a drill bit, consider investing in a coated bit if you're planning to undertake multiple drilling tasks, as it will withstand wear better than uncoated bits.

5. Brand and Quality Not all drill bits are created equal. It's wise to choose reputable brands known for producing high-quality drill bits. Cheaper, lower-quality options may seem appealing, but they often lack the engineering to deliver consistent performance, leading to frustration and potential project delays.

6. Drilling Speed Different drill bits also have different braking capabilities, which will affect the speed at which you can work. Self-drilling screws are designed to work efficiently; therefore, a compatible drill bit with good speed properties can significantly enhance your workflow.

Where to Buy Drill Bits

Drill bits can be found at a variety of retail locations, including home improvement stores, hardware stores, and online marketplaces. When shopping, look for sales or kits that include a variety of sizes and styles to suit different projects. Online reviews can also help you assess the performance of specific brands and products.

Conclusion

Selecting the right drill bit for self-drilling screws is crucial for ensuring project success and maintaining material integrity. By considering factors such as material compatibility, drill bit size, point style, coating, quality, and drilling speed, DIY enthusiasts and professionals alike can make informed purchasing decisions. Investing in high-quality drill bits will not only enhance your efficiency but also improve the overall quality of your work. Remember, the right drill bit can make all the difference in achieving a smooth and successful installation.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024