Production of 3.5% self-tapping screws in a state-of-the-art manufacturing facility for quality assurance

Understanding the Importance of 3.5% Self-Tapping Screw Production

In the realm of hardware manufacturing, self-tapping screws play a pivotal role in various construction and assembly processes. Among the many types of screws available, the 3.5% self-tapping screw has gained significant attention for its efficiency and effectiveness in joining materials. This article explores the intricacies of a self-tapping screw factory, focusing specifically on the production and applications of 3.5% self-tapping screws.

What is a Self-Tapping Screw?

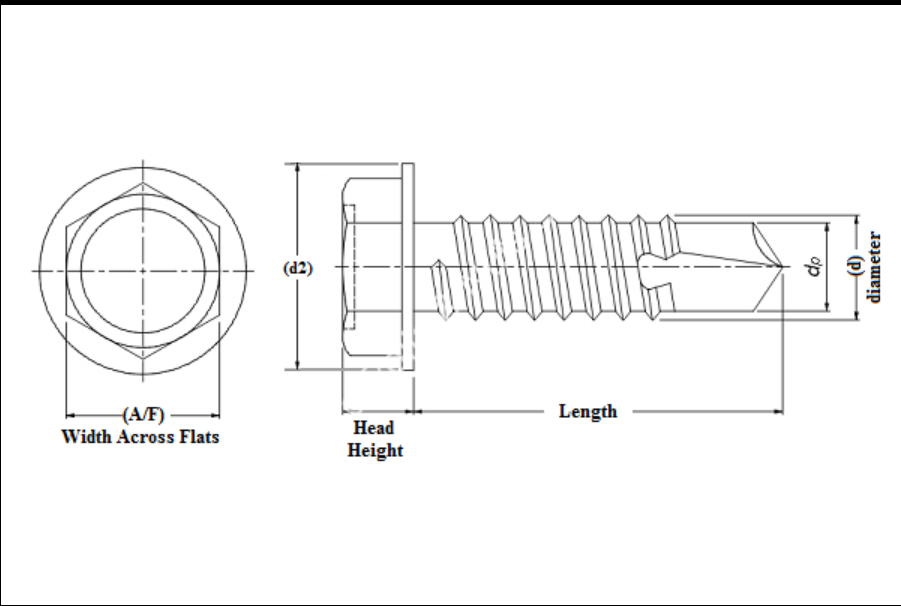

A self-tapping screw is designed to create its own hole while being driven into materials, typically plastics and thin metals. This feature eliminates the need for pre-drilled holes, thus speeding up the assembly process and reducing labor costs. The 3.5% designation commonly refers to the screw's diameter, which is approximately 3.5 mm, making it suitable for a range of applications from furniture to automotive parts.

The Manufacturing Process

The production of 3.5% self-tapping screws involves several critical steps, ensuring that the final product meets stringent quality standards.

1. Material Selection The first step in the manufacturing process is selecting high-quality materials. Steel is often the preferred choice due to its strength and durability. The alloy composition can vary based on specific requirements, with some manufacturers opting for corrosion-resistant coatings to extend the screws' lifespan.

2. Forming The selected material undergoes a forming process where it is shaped into screw configurations. This can be achieved through methods like cold forging or machining, depending on the desired thread type and finish.

3. Thread Cutting A crucial aspect of screw production is thread cutting. For self-tapping screws, threads must be designed to ensure they can efficiently tap into materials without causing damage. This involves sophisticated machinery that precisely creates the necessary profile and pitch.

3.5 self tapping screw factory

4. Heat Treatment To enhance the strength and durability of the screws, heat treatment processes are employed. These treatments alter the microstructure of the metal, providing the screws with enhanced performance characteristics.

5. Coating After the heat treatment, screws may receive protective coatings. These coatings can help prevent rust and wear, making screws suitable for both indoor and outdoor applications.

6. Quality Control Before reaching consumers, screws undergo rigorous quality control checks. Manufacturers test for strength, hardness, and dimensional accuracy to ensure that each screw meets industry standards.

Applications of 3.5% Self-Tapping Screws

The versatility of 3.5% self-tapping screws allows for their use in diverse applications. In the construction industry, they are often utilized for fastening drywall, metal framing, and roofing. Their ability to create strong connections without extensive pre-drilling makes them invaluable for quick and efficient assembly.

In the furniture industry, these screws are favored for assembling flat-pack furniture due to the ease of installation. Additionally, in automotive manufacturing, 3.5% self-tapping screws are employed to secure components, ensuring reliability and safety in vehicles.

Conclusion

The 3.5% self-tapping screw is a remarkable innovation in fastener technology, showcasing the fine balance between efficiency and functionality. A dedicated self-tapping screw factory plays a vital role in producing these essential components. By understanding the intricate manufacturing processes and diverse applications of 3.5% self-tapping screws, stakeholders can appreciate their significant contributions to various industries. As technology continues to evolve, the demand for reliable fastening solutions like self-tapping screws will remain a crucial aspect of manufacturing and construction.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024