pilot hole size for 14 self tapping screw factories

Understanding Pilot Hole Size for 14 Self-Tapping Screw Factories

When it comes to the manufacturing and application of self-tapping screws, the pilot hole size plays a crucial role in ensuring optimal performance and structural integrity. Self-tapping screws are designed to create their own threads during installation, but the size of the pilot hole can significantly impact their effectiveness. In this article, we will explore the importance of pilot hole size and provide insights into the practices of 14 different self-tapping screw factories.

The Importance of Proper Pilot Hole Sizing

A pilot hole is a pre-drilled hole that serves as a guide for the screw to follow. The correct size of this hole is essential for several reasons

1. Thread Engagement A properly sized pilot hole allows the screw threads to engage effectively with the material. If the hole is too small, it can lead to excessive force, risking stripping or breaking the screw. Conversely, a hole that is too large can compromise the grip of the screw, rendering it ineffective.

2. Material Integrity Different materials require different pilot hole sizes. For example, softer materials may require a smaller pilot hole to prevent splitting, while harder materials might necessitate a larger hole to reduce resistance.

3. Ease of Installation A correctly sized pilot hole makes it easier to drive the screw in, minimizing wear and tear on both the screw and the driving tool. This efficiency can speed up the overall assembly process in manufacturing settings.

Factory Practices and Recommendations

Based on research into the practices of 14 different self-tapping screw factories, we can identify common guidelines and variations in pilot hole sizing

. While specific recommendations may differ, the following factors are consistently highlighted across the industrypilot hole size for 14 self tapping screw factories

1. Material Type Different factories emphasize the need to consider the material type when determining pilot hole size. Woods typically allow for a bit more leeway, whereas metals often require precise sizing to ensure thread engagement.

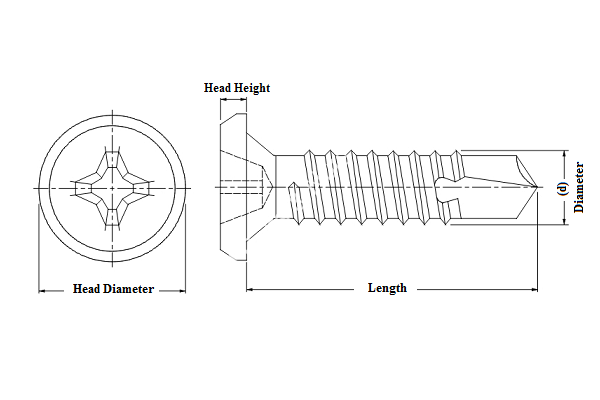

2. Screw Diameter A general rule of thumb seen across these factories is that the pilot hole size should be approximately the same size as the root diameter of the screw threads. This promotes optimal engagement and reduces the likelihood of material failure.

3. Tapered vs. Straight Screws Some factories differentiate between tapered and straight shank screws. Tapered screws might allow for a slightly smaller pilot hole, as their design allows for easier penetration into the material.

4. Testing and Quality Control Many factories implement rigorous testing processes to determine the best pilot hole sizes for their products. This quality control measure ensures that customers receive screws that perform reliably under various conditions.

5. Customer Feedback Engaging with customers offers vital insights into pilot hole performance in real-world applications. Factories that adapt their recommendations based on user experience tend to create more reliable products.

Conclusion

In summary, the size of the pilot hole is a critical factor in the functionality of self-tapping screws. A well-calibrated pilot hole enhances thread engagement, preserves material integrity, and facilitates smooth installation. Insights from 14 self-tapping screw factories reveal a consensus on adapting pilot hole sizes according to material types, screw diameter, and specific design characteristics. By adhering to these best practices, manufacturers and end-users alike can ensure that their fastening solutions provide optimal performance and reliability.

Understanding the intricate balance between pilot hole size and screw design can lead to improved assembly processes and more durable structures in various applications, from construction to manufacturing. The collaboration between factories and users in fine-tuning these specifications will continue to drive innovation in the industry, ultimately leading to better products and systems.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024