Jan . 14, 2025 10:41

Back to list

phosphated drywall screw

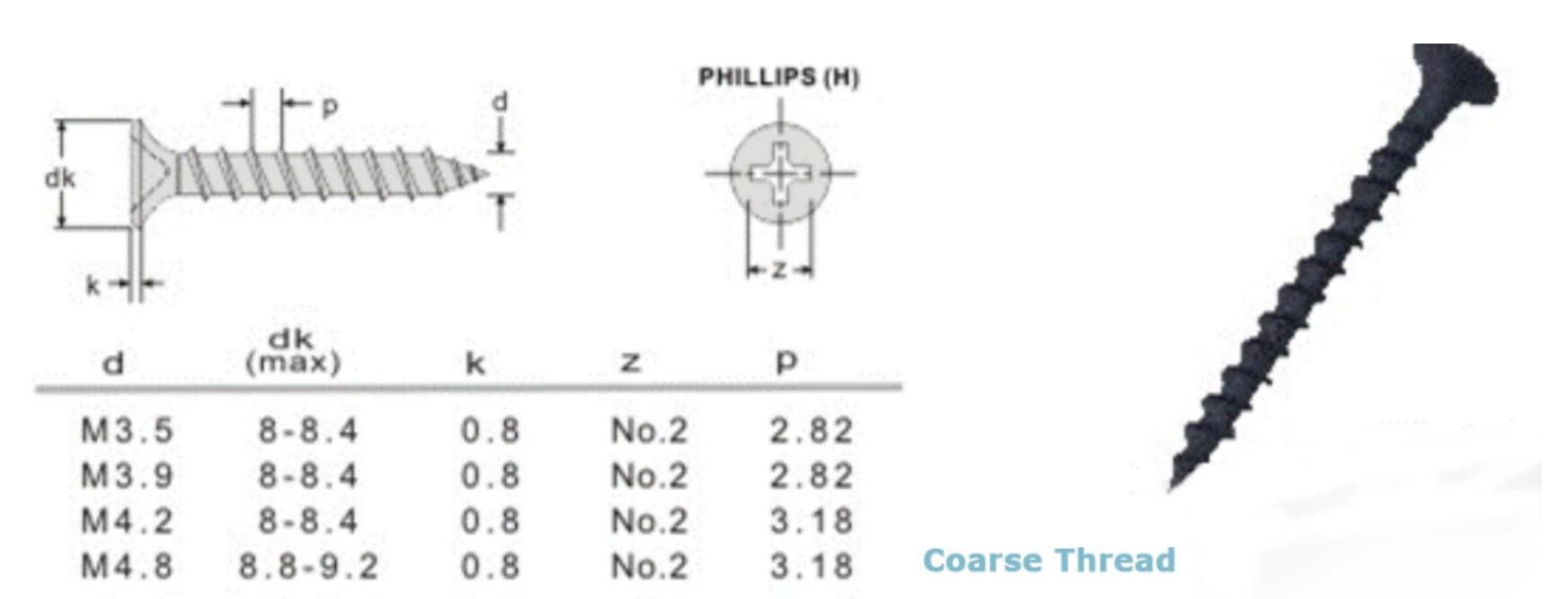

Phosphated drywall screws are a crucial component in construction projects and renovations, widely recognized for their durability and efficiency in fastening drywall to wood or metal studs. Experience with these screws reveals that phosphated coating enhances resistance to corrosion, making them ideal for indoor environments where humidity and temperature fluctuations might otherwise promote rust. From my extensive experience in the construction industry, phosphated drywall screws have consistently outperformed other types of screws, reducing maintenance costs and increasing the longevity of structures.

Trustworthiness in construction tools and materials is paramount, given the potential consequences of failure. Phosphated drywall screws are manufactured under strict quality control processes to ensure each batch meets precise specifications. From the uniformity of the phosphated coating to the precision threading on each screw, manufacturers rigorously test these components to avoid issues on the job site that could lead to structural weaknesses. This level of scrutiny and diligence ensures that contractors and home builders can trust phosphated drywall screws to perform consistently under different conditions. In conclusion, phosphated drywall screws represent a blend of innovation and reliability that the construction industry values highly. Leveraging years of first-hand experience confirms their suitability across varying environmental conditions, from damp basements to climate-controlled commercial spaces. Their design and construction are backed by expert recommendations and trust from the field. Using phosphated drywall screws not only meets the practical needs of fastening drywall effectively but also aligns with long-term perspectives on quality building practices. As such, they remain a preferred choice within the toolkit of construction specialists globally, establishing themselves as a small yet invaluable component of modern construction methodology.

Trustworthiness in construction tools and materials is paramount, given the potential consequences of failure. Phosphated drywall screws are manufactured under strict quality control processes to ensure each batch meets precise specifications. From the uniformity of the phosphated coating to the precision threading on each screw, manufacturers rigorously test these components to avoid issues on the job site that could lead to structural weaknesses. This level of scrutiny and diligence ensures that contractors and home builders can trust phosphated drywall screws to perform consistently under different conditions. In conclusion, phosphated drywall screws represent a blend of innovation and reliability that the construction industry values highly. Leveraging years of first-hand experience confirms their suitability across varying environmental conditions, from damp basements to climate-controlled commercial spaces. Their design and construction are backed by expert recommendations and trust from the field. Using phosphated drywall screws not only meets the practical needs of fastening drywall effectively but also aligns with long-term perspectives on quality building practices. As such, they remain a preferred choice within the toolkit of construction specialists globally, establishing themselves as a small yet invaluable component of modern construction methodology.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News