Self-Drilling Pan Head Screws Manufacturer Quality and Efficiency Guaranteed

Exploring the World of Pan Head Self-Drilling Screws A Factory's Perspective

When it comes to construction and manufacturing, the choice of fasteners can significantly impact the quality and durability of projects. Among various options, pan head self-drilling screws have gained considerable popularity, particularly in industrial applications. This article delves into the characteristics, manufacturing process, and advantages of these essential fasteners from a factory's perspective.

Understanding Pan Head Self-Drilling Screws

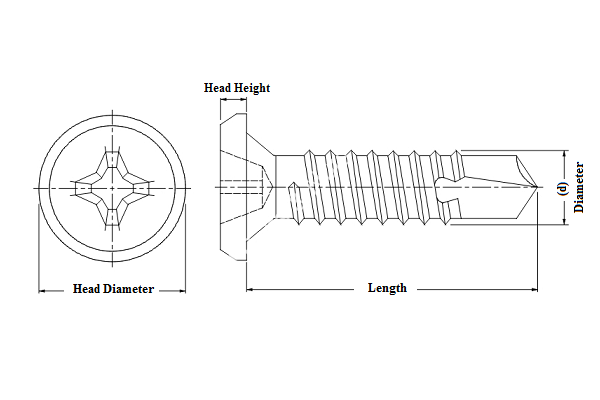

Pan head self-drilling screws are designed with a distinct rounded top, allowing for a larger bearing surface that distributes load across a wider area. This design not only improves the aesthetic appeal of the finished product but also enhances the screw's ability to resist stripping. The unique self-drilling feature means that these screws can create their own pilot holes as they are driven into the material, eliminating the need for pre-drilling, which can save time and labor costs.

These screws are made from high-quality steel and often coated for added corrosion resistance, ensuring longevity even in harsh environments. They come in various sizes and thread types, making them suitable for a wide range of materials, including metal, wood, and plastic.

The Manufacturing Process

At a typical pan head self-drilling screw factory, the manufacturing process begins with high-grade steel wire. The wire undergoes a process of drawing, where it is shaped into the desired diameter. This is followed by cold forging, which gives the screw its primary shape and characteristics. During this phase, metal is shaped at room temperature, which helps maintain its strength and integrity.

Once forged, the screws enter a series of operations that include threading and heat treatment. The threading process can be performed using a variety of techniques, including rolling and cutting, depending on the desired finish and application. Heat treatment follows, where the screws are subjected to controlled heating and cooling processes to enhance their hardness and tensile strength.

pan head self drilling screw factory factory

Next, the screws undergo surface treatment. This could involve galvanization, black oxide, or other protective coatings that help prevent rust and corrosion. The choice of coating depends on the intended application of the screws and the environment they will be used in.

Quality Control and Testing

Quality control is a critical aspect of screw manufacturing. Factories implement rigorous testing to ensure that each batch of screws meets industry standards. This includes checking dimensions, tensile strength, and corrosion resistance. Advanced testing equipment is employed, including tensile testing machines and salt-spray tests, to simulate real-world conditions and ensure that the screws perform as expected.

Advantages of Pan Head Self-Drilling Screws

The benefits of using pan head self-drilling screws extend beyond their simplicity and efficiency. Firstly, their unique design allows for easy installation, making them especially valuable in construction projects where time and labor costs are a concern. Additionally, because they can cut through material without the need for pre-drilling, they are ideal for applications where precision and speed are paramount.

Moreover, the corrosion-resistant coatings enhance durability, making these screws suitable for outdoor and marine applications where exposure to moisture is a concern. Their versatility allows them to be used in HVAC systems, metal framing, and even in automotive manufacturing.

Conclusion

In conclusion, pan head self-drilling screws represent a remarkable fusion of design, efficiency, and practicality in the fastener industry. From the meticulous manufacturing process at the factory to their effective applications in various industries, these screws are indispensable tools that contribute to the success of countless projects. As demand for reliable and efficient fasteners continues to grow, pan head self-drilling screws will undoubtedly remain at the forefront of construction and manufacturing solutions. Whether you are a contractor or a DIY enthusiast, understanding the advantages of these screws can elevate the quality of your work and enhance the longevity of your projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024