pan head self drilling screw factory company

The Rise of Pan Head Self-Drilling Screw Manufacturers

In recent years, the demand for fasteners, particularly self-drilling screws, has surged in various industries, including construction, automotive, and manufacturing. Among these, pan head self-drilling screws have gained significant popularity due to their unique design and functionality. This article delves into the characteristics, applications, and the increasing prominence of pan head self-drilling screw factories.

What are Pan Head Self-Drilling Screws?

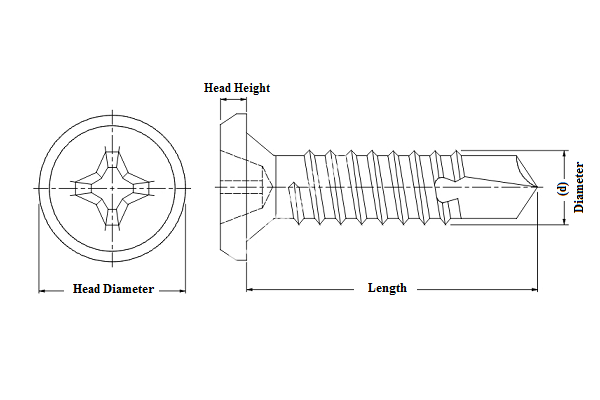

Pan head self-drilling screws are specialized fasteners characterized by a rounded, dome-like head that allows for a greater surface area. This design provides a secure hold on materials, making it less likely for the screws to strip. The self-drilling capability is another defining feature, as it allows these screws to create their own holes in various substrates without requiring pre-drilling. This not only saves time during installation but also enhances efficiency, particularly in projects that involve multiple fastening operations.

Advantages of Pan Head Self-Drilling Screws

1. Ease of Use The primary advantage of self-drilling screws is their ease of installation. Workers can easily drive them into different materials, including metal, wood, and plastic, without the need for additional equipment. This factor is particularly beneficial in construction settings where time is a crucial resource.

2. Versatile Applications Due to their robust design, pan head self-drilling screws are versatile and suitable for a wide array of applications. They are commonly used in metal-to-metal and metal-to-wood connections, making them indispensable in structural applications, HVAC installations, and for securing sheet metal.

3. Higher Strength The pan head design ensures a stronger grip compared to other types of screw heads, such as flat or round heads. This strength is essential in load-bearing applications, where fasteners must withstand significant forces.

4. Corrosion Resistance Many pan head self-drilling screws are coated with materials that enhance their corrosion resistance. Stainless steel and galvanized finishes are commonly used to prolong the lifespan of the screws, especially in outdoor settings or environments exposed to moisture.

pan head self drilling screw factory company

The Growing Market for Self-Drilling Screw Factories

As industries continue to evolve and modernize, the need for high-quality fasteners has become more pronounced. This trend has led to the establishment and growth of pan head self-drilling screw factories around the world. These factories are focused on producing innovative and reliable fasteners that meet the increasing demands of various sectors.

1. Investment in Technology Modern screw manufacturing facilities are equipped with advanced technology and machinery. This investment allows for the production of screws that meet stringent quality standards. Automated production lines enable factories to achieve high levels of efficiency, reducing costs and increasing output.

2. Research and Development Many pan head self-drilling screw manufacturers are investing in R&D to improve the performance of their products. This includes developing new coatings for better corrosion resistance and creating unique thread designs that enhance the screwing process.

3. Sustainability With a growing emphasis on sustainability, many factories are adopting eco-friendly practices. This involves sourcing raw materials responsibly and exploring methods to reduce waste during the manufacturing process. As sustainability becomes a cornerstone of construction and manufacturing, consumers are more inclined to purchase products from factories that prioritize environmental responsibility.

4. Global Reach The global market for fasteners is on the rise, and pan head self-drilling screw factories are tapping into this trend by expanding their export capabilities. This expansion allows them to reach new markets and cater to a broader customer base.

Conclusion

In summary, the rise of pan head self-drilling screw manufacturers marks a significant evolution in the fastener industry. With their ease of use, versatility, strength, and advancements in manufacturing technology, these screws have become essential components across numerous sectors. As demand continues to grow, the factories producing these innovative fasteners are not just responding to consumer needs but are also contributing to the advancement of construction and manufacturing processes worldwide. As we look to the future, the pan head self-drilling screw will likely remain a staple in the toolkit of builders and manufacturers, underscoring the importance of this seemingly simple but incredibly valuable fastener.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024