Optimal Hole Dimensions for Self-Tapping Screws in Plastic Applications from Leading Suppliers

Understanding Self-Tapping Screw Hole Size for Plastics A Guide for Suppliers

When it comes to fastening materials in the manufacturing and construction industries, self-tapping screws are an essential component, particularly when working with plastics. Properly sized screw holes can significantly enhance the integrity of the joint and the performance of the finished product. This article explores the importance of screw hole sizing in plastics and provides guidance for suppliers looking to optimize their offerings.

The Role of Self-Tapping Screws

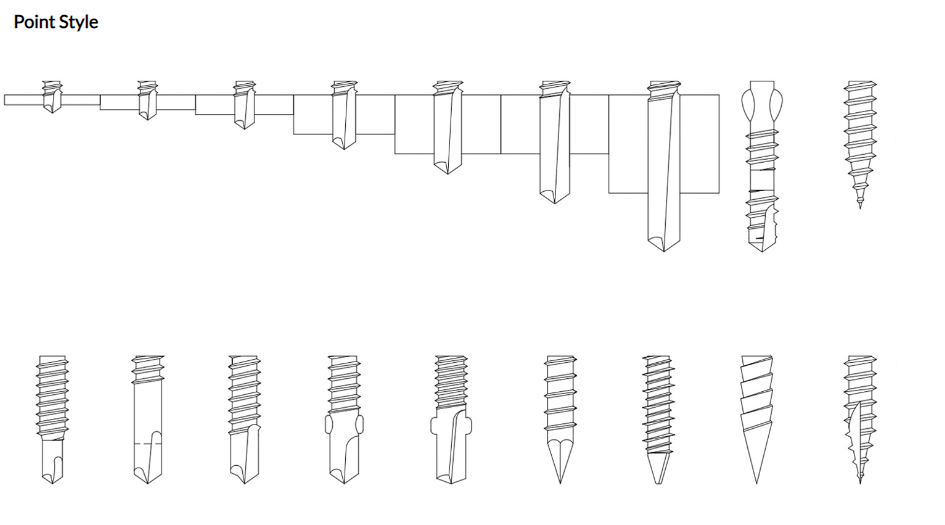

Self-tapping screws are designed to create their own hole as they are driven into materials, which is a significant advantage when working with various substrates, including plastics. These screws reduce assembly time and can eliminate the need for pre-drilled holes, making them a popular choice in numerous applications, from manufacturing to DIY projects.

Importance of Hole Size

The size of the screw hole is crucial when using self-tapping screws, particularly with plastics. An improperly sized hole can lead to several issues, including poor fastening strength, the risk of cracking or splitting the material, and eventual failure of the assembly. Therefore, understanding the optimal hole size is fundamental for suppliers and users alike.

1. Foreign Material Removal When using self-tapping screws, the ability to displace material is essential. The gap size where the screw penetrates should be adequate, allowing for proper displacement without causing damage to the plastic. If the hole is too small, it can lead to material stress and cracking, while a hole that is too large might not allow for sufficient grip from the screw threads.

2. Screw Diameter and Thread Design The diameter of the screw and the design of its threads also play a significant role in determining the appropriate hole size. Suppliers must ensure that they provide comprehensive specifications that detail the recommended hole sizes based on different screw diameters and thread types. For example, a screw with a coarse thread may require a larger pilot hole compared to a fine-thread screw.

3. Material Thickness and Type Different plastics have varying characteristics, including flexibility, hardness, and thermal expansion. The thickness of the plastic also impacts hole size; thicker materials may require different approaches than thinner ones. Suppliers should equip their customers with the knowledge to assess which hole sizes work best with specific plastic types and thicknesses.

self tapping screw hole size for plastics suppliers

Recommendations for Suppliers

For suppliers in the industry, providing detailed guidance on screw hole sizes tailored for various types of plastics is crucial. Here are several recommendations

- Standardization Develop standard hole size recommendations based on screw diameter, thread type, and plastic characteristics. This standardization can help streamline the selection process for manufacturers using your products.

- Educational Resources Create educational materials, such as datasheets or online resources, that detail the relationship between screw hole sizes and plastic applications. Including practical examples and charts can enhance understanding.

- Testing and Feedback Encourage customers to share feedback based on their own experiences with self-tapping screws in various applications. This feedback can guide further improvements and adjustments in recommendations.

- Promoting Best Practices Host workshops or webinars to educate both suppliers and end-users on the proper techniques for selecting and installing self-tapping screws in plastics. This knowledge-sharing can contribute to better product performance and satisfaction.

Conclusion

In conclusion, understanding self-tapping screw hole sizes is vital for suppliers working with plastics. By providing accurate specifications, educational resources, and fostering open communication with customers, suppliers can enhance the effectiveness of their products and contribute to successful assembly processes across various applications. This investment in knowledge and support will set suppliers apart in a competitive marketplace.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024