Optimal Drywall Screw Spacing for Affordable and Professional Installation Techniques Explained

Understanding Cheap and Proper Drywall Screw Spacing

When it comes to constructing or renovating spaces, drywall installation is an essential step that requires careful consideration of various factors, including materials, tools, and techniques. Among these, the spacing of drywall screws may seem like a trivial detail, but it plays a crucial role in the longevity, integrity, and aesthetic appeal of the finished product. This article will discuss the importance of proper drywall screw spacing, along with tips for achieving an effective and cost-efficient installation.

Importance of Proper Drywall Screw Spacing

The spacing of drywall screws is vital for the stability and reliability of the drywall. Proper screw placement ensures that the drywall panels are securely attached to the framing, minimizing the risk of cracks, sagging, or movement over time. If screws are placed too far apart, the panels may not hold up under stress, leading to future repair costs and frustration.

Moreover, the aesthetic quality of the finished surface heavily depends on how well the drywall is secured. Properly spaced screws reduce the chances of imperfections such as bulges or dimples that can disrupt the smoothness of painted or textured surfaces. Therefore, understanding the recommended screw spacing can not only save money on repairs but also enhance the visual appeal of a room.

Recommended Screw Spacing

When installing drywall, the general recommendation for screw spacing is typically 16 inches on center for wall studs and 12 inches on center for ceilings. This means that screws should be driven along the edges of the drywall panel every 12 to 16 inches, and about 8 inches apart at the joints between panels. This spacing theory accounts for the average weight and pressure exerted on the drywall, ensuring that the panel remains secure.

cheap proper drywall screw spacing

In certain instances, you may opt for slightly closer spacing, particularly if the drywall will be subjected to heavier loads, such as mounted shelves or cabinets. Remember to consider the specific application and structural requirements of your project, as these guidelines can vary based on building codes and personal preferences.

Cost-Effective Practices

While the focus of this article has been on achieving proper screw spacing, it’s worth noting that there are several inexpensive ways to make your drywall installation both effective and budget-friendly. First and foremost, purchasing quality drywall screws in bulk can significantly reduce costs.

Additionally, using the right tools, such as an electric screw gun, can improve installation speed and accuracy. For the best results, ensure that you’re using screws designed for drywall, typically with a bugle head that sits flush with the surface.

Lastly, consider collaborating with someone experienced in drywall installation or watching tutorial videos online. Proper techniques can minimize errors that lead to costly repairs down the line.

Conclusion

In summary, while it may seem like a simple detail, proper drywall screw spacing is vital for achieving a stable, visually appealing, and long-lasting installation. By adhering to recommended spacing guidelines and incorporating cost-effective techniques, you can ensure a successful drywall project that meets your budgetary constraints. Remember that investing in quality practices from the outset will ultimately save you time and money in maintenance and repairs down the line. So as you embark on your next renovation or construction project, give drywall screw spacing the consideration it truly deserves.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

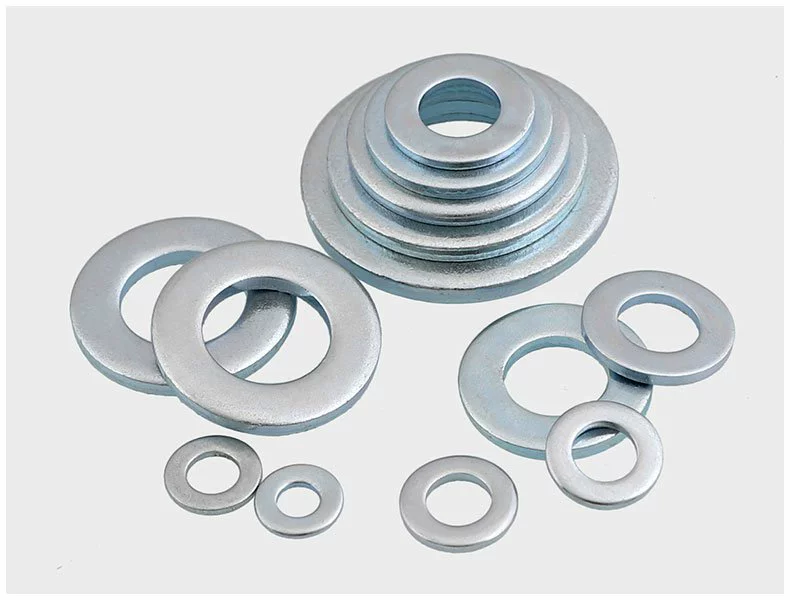

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024