OEM Spring Washer Design Specifications and Technical Drawings Overview

Understanding OEM Spring Washer Drawings A Comprehensive Guide

In the realm of manufacturing and mechanical engineering, precision is paramount. One of the key components often overlooked yet critical in machinery assembly is the spring washer. Provided by Original Equipment Manufacturers (OEMs), spring washers serve essential functions, including providing tension, maintaining tightness in bolts, and absorbing shock. This article delves into the intricacies of OEM spring washer drawings, their significance, and how to interpret them effectively.

What is a Spring Washer?

Spring washers, also known as spring lock washers, are circular devices with a slight rise in the center, designed to exert a force between components. Their primary purpose is to prevent the loosening of bolts or nuts due to vibration, ensuring the integrity of an assembly over time. Typically made from materials like steel, stainless steel, or other alloys, these washers are essential in various applications, from automotive to aerospace.

The Importance of OEM Spring Washer Drawings

OEM spring washer drawings are technical documents that provide comprehensive details about the design, dimensions, materials, and specifications of the washers. These drawings are crucial for manufacturers, engineers, and quality assurance teams alike for several reasons

1. Precision Manufacturing OEM drawings provide the exact specifications needed for precision manufacturing. This ensures that every washer produced meets the high standards required in complex machinery.

2. Quality Control Detailed drawings serve as reference points for quality control processes, ensuring that each component manufactured adheres to the specified standards, thus minimizing defects.

3. Interchangeability In engineering, interchangeability is vital. OEM drawings indicate dimensions and tolerances that allow for the seamless integration of components from different manufacturers, thereby facilitating maintenance and repairs.

4. Legal Compliance Compliance with industry standards and regulations is paramount in manufacturing. OEM drawings often include compliance marks that indicate adherence to specific industry guidelines.

Key Elements of an OEM Spring Washer Drawing

Understanding the language of these drawings is essential for effective communication within manufacturing and engineering contexts. Here are the key components typically found in an OEM spring washer drawing

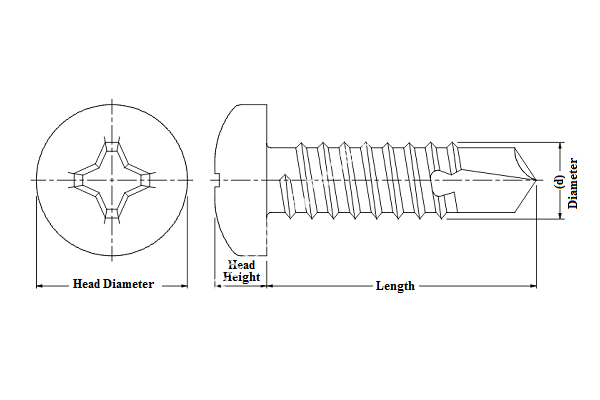

1. Dimensions This section provides the essential measurements of the washer, including inner diameter, outer diameter, and thickness. Understanding these dimensions is critical for ensuring the correct fit within assemblies.

oem spring washer drawing

2. Material Specifications OEM drawings usually specify the material from which the washer is to be made. This can range from carbon steel to various grades of stainless steel, reflecting the washer's intended application, including considerations for corrosion resistance.

4. Tolerances Tolerances define the allowable variations in dimensions. They are crucial parameters in engineering, as they dictate how much deviation from the nominal dimensions is acceptable without compromising the washer's function.

5. Markings and Symbols Various symbols may be used within the drawing to convey additional information, such as the orientation of the washer, assembly instructions, or safety warnings.

Interpreting OEM Spring Washer Drawings

Interpreting OEM spring washer drawings requires a blend of technical understanding and practical knowledge. Here are key steps

1. Familiarize Yourself with Engineering Symbols Understanding common engineering symbols and annotation styles will facilitate quicker comprehension of the drawing.

2. Cross-Reference with Specifications If multiple parts or components are involved, ensure that all specifications align with the overall assembly requirements.

3. Consult Standards Familiarize yourself with industry standards related to spring washers and fasteners. This knowledge enhances your ability to apply drawing details in real-world applications.

4. Engage Experts When in doubt, consulting with engineers or manufacturers who specialize in fasteners can provide clarity and enhance your understanding.

Conclusion

OEM spring washer drawings are indispensable tools in the manufacturing and assembly of mechanical components. They encapsulate crucial information needed to ensure that spring washers perform their intended functions effectively. By understanding the various elements of these drawings and their importance in manufacturing, engineers and technicians can better appreciate the role of spring washers in maintaining the integrity and functionality of mechanical assemblies. As industries continue to advance, the importance of such precise and detailed documentation will only grow, underscoring the pivotal role of OEMs in ensuring quality and reliability in engineering.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024