Custom Spring Tension Washers for OEM Applications and Enhanced Performance Solutions

Understanding OEM Spring Tension Washers Features and Applications

Spring tension washers, often referred to as OEM (Original Equipment Manufacturer) washers, are integral components in various mechanical assemblies. These washers are designed to apply a consistent tension and help maintain the integrity of the joint they are part of. With their unique design and functionality, OEM spring tension washers play a crucial role in enhancing the performance and longevity of machinery.

What are OEM Spring Tension Washers?

OEM spring tension washers are specialized washers engineered to provide a resilient force when compressed. They are typically made from high-quality materials such as stainless steel, carbon steel, or other alloys that offer durability and resistance to corrosion. The primary characteristic of these washers is their ability to maintain a consistent load, even in the presence of vibrations and fluctuations in temperature. This makes them invaluable in applications where safety and reliability are paramount.

Key Features

1. Consistent Force One of the standout features of OEM spring tension washers is their capability to exert a uniform load consistently. This property prevents loosening in bolted connections, which can lead to equipment failure.

2. Vibration Resistance These washers are particularly effective in applications involving high vibrations, such as automotive and industrial machinery, where traditional washers might fail or lose their effectiveness over time.

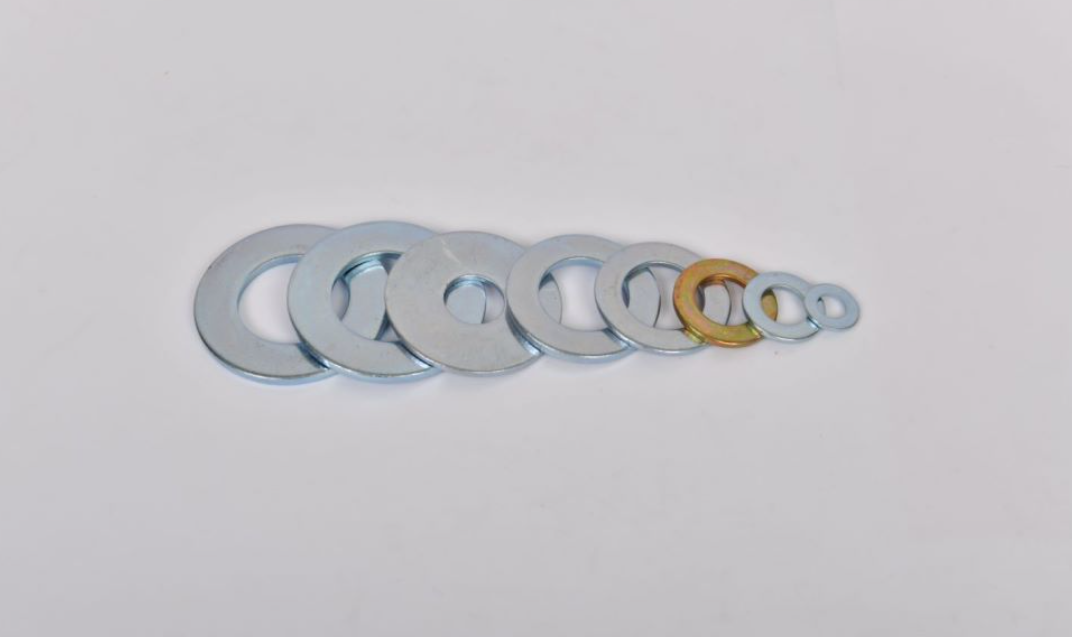

oem spring tension washer

3. Customization OEM manufacturers often provide customization options for spring tension washers to meet specific requirements of different equipment. This might include variations in size, thickness, and material types, allowing for better fit and function in various applications.

Applications

OEM spring tension washers are widely used across many industries, including automotive, aerospace, electronics, and construction. In automotive applications, they help maintain the integrity of engine components, ensuring that critical parts remain secured and do not loosen over time. In the aerospace sector, their reliable performance is crucial for maintaining the structural integrity of aircraft assemblies subjected to extreme conditions.

In the electronics industry, spring tension washers are often used in circuit boards and enclosures to ensure effective grounding and electrical connections. Furthermore, in construction, these washers are employed in various structural applications to ensure safety and stability in load-bearing installations.

Conclusion

In conclusion, OEM spring tension washers are vital components that contribute significantly to the reliability and longevity of mechanical systems. Their ability to provide consistent tension, resist vibrations, and be tailored to fit specific needs makes them indispensable across various industries. As technology advances and demands for reliable machinery increase, the role of OEM spring tension washers will continue to grow, ensuring that equipment operates safely and efficiently. Understanding their features and applications can help businesses select the right components for their needs, ultimately leading to enhanced performance and reduced maintenance costs.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024