oem screw drywall to drywall

The Essential Guide to OEM Screws for Drywall Installation

When it comes to drywall installation, choosing the right screws is crucial for ensuring the integrity and durability of the structure. Original Equipment Manufacturer (OEM) screws designed specifically for drywall have gained popularity due to their reliability and compatibility with various materials. This article explores the significance of OEM drywall screws, their features, and the best practices for using them effectively.

Understanding OEM Drywall Screws

OEM screws refer to fasteners produced by a manufacturer that specializes in creating high-quality components tailored for specific purposes. In the context of drywall installation, these screws are engineered to meet the unique requirements of securing drywall sheets to wooden or metal studs. Unlike generic screws, OEM drywall screws are tested for optimal performance, corrosion resistance, and minimal strip-out risk.

Features of OEM Drywall Screws

1. Material Quality OEM drywall screws are typically made from high-strength steel with a coating that prevents rust and corrosion. This durability ensures that the screws maintain their integrity even in humid environments, making them ideal for various applications.

2. Thread Design The threads on OEM drywall screws are specifically designed to maximize holding power. The fine threads grip the drywall paper without damaging it, while larger spaced threads can be found on special-purpose screws for securing into wood.

3. Sharp Points Most OEM drywall screws feature sharp, self-drilling points that allow for easy penetration into the drywall and underlying framing. This design element not only reduces the need for pre-drilling but also speeds up the installation process.

4. Head Design The heads of OEM drywall screws are usually bugle-shaped, allowing them to sink into the drywall without tearing the paper. This creates a flush surface that is easy to finish with joint compound.

oem screw drywall to drywall

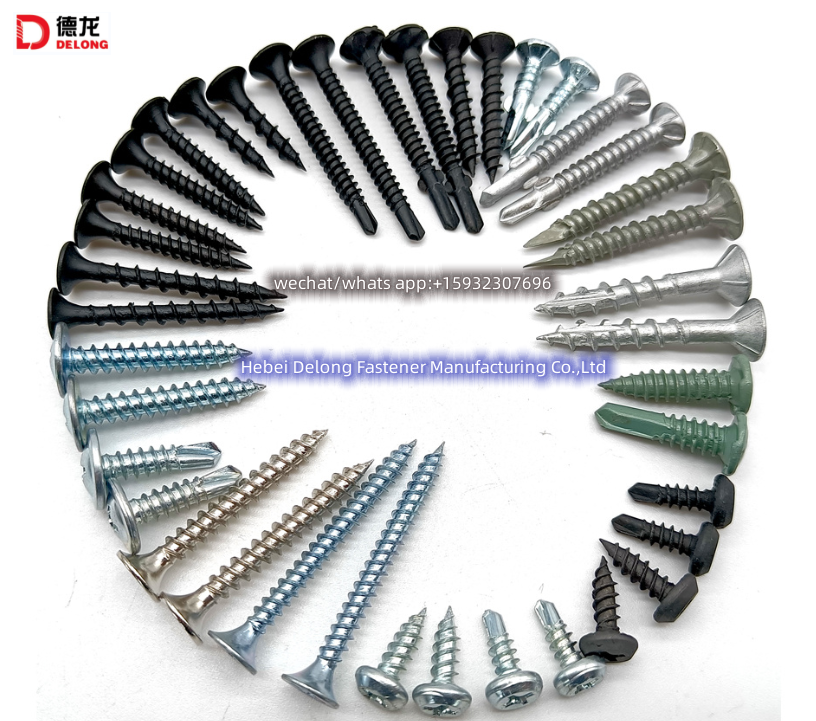

5. Variety OEM manufacturers often provide a range of screws tailored for different drywall installations, including variations in length, thread type, and head styles. This variety ensures that users can select the most suitable screw for their specific project.

Best Practices for Using OEM Drywall Screws

1. Select the Right Screw Before beginning your drywall installation project, it’s essential to choose the correct OEM screw. Consider factors such as the thickness of the drywall, the type of framing (wood or metal), and the specific application (walls or ceilings).

2. Installation Techniques When using OEM screws, maintain a consistent spacing pattern, typically 12 to 16 inches apart, depending on building codes and the weight of the drywall. Be cautious not to overdrive the screws, which can cause damage to the drywall or lead to screw strip-out.

3. Use Proper Tools Utilize a power drill or screwdriver with adjustable torque settings to prevent overdriving. A screw gun designed specifically for drywall can provide the best results by automatically setting the depth of penetration.

4. Check for Alignment After hanging the drywall, inspect the screw alignment to ensure that all screws are properly set. Any irregularities can affect the finishing process, leading to cracks or visible dimples.

5. Finishing Touches Once the drywall is securely in place, cover the screw heads with joint compound. This process not only conceals the screws but also creates a smooth surface for painting or wallpapering.

Conclusion

Choosing OEM screws for drywall installation can significantly enhance the quality of your project, ensuring a sturdy and professional finish. With their superior design and durability, they provide an effective solution for both DIY enthusiasts and professional contractors. By adhering to best practices during installation, you can achieve a flawless result that stands the test of time. Whether you’re embarking on a small renovation or a large-scale construction project, investing in OEM drywall screws is a decision that pays off in the long run.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024