oem nail or screw drywall

Understanding OEM Nails and Screws for Drywall Applications

When it comes to construction and interior design, the choice of tools and materials can have a significant impact on the quality and durability of the finished product. Among the various components used in drywall installation, OEM (Original Equipment Manufacturer) nails and screws play a crucial role. This article aims to provide a comprehensive overview of OEM nails and screws specifically designed for drywall applications.

What Are OEM Nails and Screws?

OEM nails and screws are fasteners that are manufactured by a company to meet specifications that are often used by other brands or for specific applications. The term OEM often refers to parts that are made to be identical in design, quality, and fit to those used by major manufacturers. These nails and screws are integral to securing drywall sheets to framing structures such as studs and joists.

Types of Fasteners for Drywall

When installing drywall, several types of fasteners can be used, but nails and screws are the primary options. Let's delve into their distinct characteristics

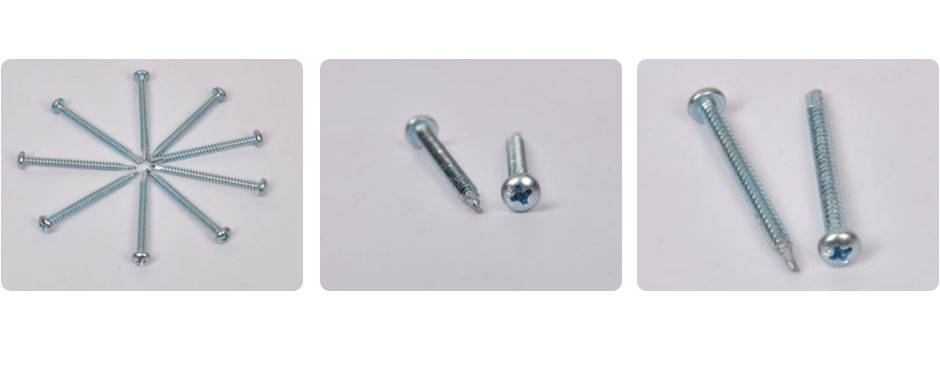

1. Drywall Screws These are specifically designed for fastening drywall sheets to wooden or metal framing. They come in various lengths and types, including coarse-thread and fine-thread screws. Coarse-thread screws are better suited for wood studs, while fine-thread screws work well with metal studs. The design of drywall screws allows for easy installation with a power drill, reducing the time and effort required during the installation process.

2. Drywall Nails Traditionally used before the widespread adoption of screws, drywall nails are still employed in certain situations. They are usually longer than standard nails, providing better holding power for drywall sheets. However, nails can sometimes lead to nail pops, where the nail lifts out of the drywall surface over time. While they can be quicker to install than screws, they generally don’t offer the same level of strength and durability as screws.

The Advantages of Using OEM Fasteners

1. Quality Assurance OEM nails and screws undergo rigorous testing and quality assurance processes to ensure they meet specific standards. This is particularly important in drywall installation, where a secure fastening system is critical to prevent sagging or cracking in the drywall.

oem nail or screw drywall

2. Compatibility When using OEM fasteners, builders can be assured of compatibility with various drywall types and thicknesses. This versatility can simplify the selection process, as these fasteners are designed to work seamlessly with most standard drywall materials.

3. Cost-Effectiveness OEM components are often offered at competitive prices compared to brand-name alternatives, providing builders with a cost-effective solution without sacrificing quality.

4. Availability Many suppliers stock a wide range of OEM nails and screws, making them easily accessible for construction projects of any scale. This availability ensures that builders can find the right fasteners without delay, thus keeping projects on schedule.

Installation Tips for Drywall Fasteners

1. Correct Spacing When installing drywall screws, maintain proper spacing to ensure optimal support. Generally, screws should be placed every 12 inches along the edges and every 16 inches in the field of the drywall sheet.

2. Using the Right Tools A power drill with a clutch setting is ideal for installing screws, as it prevents over-torquing and potential damage to the drywall. Manual installation with a hammer is possible for nails, but care should be taken to avoid damaging the board.

3. Consider Using a Drywall Screw Gun For large projects, investing in a drywall screw gun can speed up the process significantly, providing consistent depth and reducing the risk of damaging the material.

Conclusion

In summary, OEM nails and screws are essential components in the drywall installation process. Their quality, compatibility, and cost-effectiveness make them a preferred choice among builders and contractors. Understanding the differences between screws and nails, as well as the proper techniques for their installation, can lead to successful and durable drywall applications. Whether you are a seasoned contractor or a DIY enthusiast, choosing the right fasteners is key to achieving a professional finish in any drywall project.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024