OEM Galvanized Chipboard Nails for Reliable Construction and Woodworking Applications

The Importance of OEM Galvanized Chipboard Nails in Construction and Manufacturing

In the world of construction and manufacturing, the choice of materials and fasteners can significantly influence the durability and stability of products and structures. One of the most reliable and widely used fasteners is the OEM (Original Equipment Manufacturer) galvanized chipboard nail. These nails are specifically designed for chipboard applications, making them an essential component in many projects, from furniture assembly to structural frameworks.

What Are OEM Galvanized Chipboard Nails?

OEM galvanized chipboard nails are specialized fasteners coated with zinc to enhance their resistance to rust and corrosion. This galvanization process involves applying a protective zinc layer to the steel nail, ensuring longevity and reliability in various environments. Chipboard, a common material in furniture and fixtures due to its affordability and versatility, requires fasteners that can securely bond the pieces together without compromising the integrity of the board. OEM manufacturers produce these nails with specific dimensions, materials, and coatings tailored to meet industry standards and customer needs.

The Advantages of Using Galvanized Nails

1. Corrosion Resistance One of the main advantages of galvanized chipboard nails is their resistance to corrosion. This feature is particularly crucial in humid or damp environments where untreated nails would quickly deteriorate. The zinc coating acts as a barrier against moisture, ensuring that the fasteners remain intact for years.

2. Strength and Durability These nails are engineered to provide exceptional holding power. Their strong composition ensures that they can withstand significant stress and tension, making them ideal for various applications where load-bearing capacity is critical.

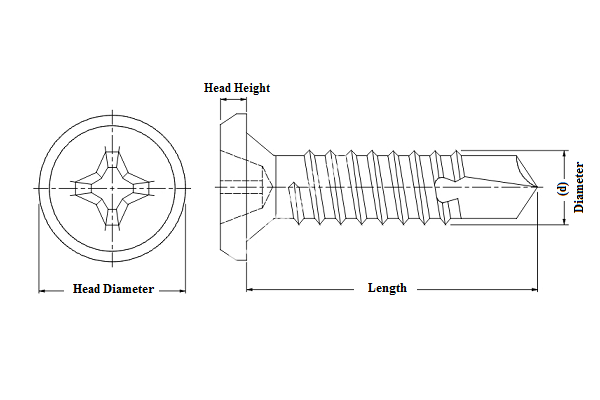

oem galvanized chipboard nail

3. Ease of Use OEM galvanized chipboard nails are designed for easy installation. Their sharp tips and optimal length allow for quick penetration into chipboard, reducing the time and effort needed during assembly or construction. This efficiency translates to lower labor costs and faster project completion.

4. Compatibility Galvanized chipboard nails are specifically designed to work seamlessly with chipboard materials. They minimize the risk of splitting or damaging the board during installation, ensuring a smoother application process. Moreover, they can also be used effectively with other types of wood and engineered materials.

Applications in Construction and Furniture Manufacturing

Galvanized chipboard nails play a crucial role in various sectors, primarily in construction and furniture manufacturing. In construction, they are often used in framing, roofing, flooring, and cabinetry. Their strength and moisture resistance make them suitable for both interior and exterior applications.

In furniture manufacturing, these nails are essential in assembling items like cabinets, desks, and shelves where chipboard is frequently employed. The secure fastening provided by galvanized nails helps maintain the structural integrity of furniture, leading to longer-lasting products that can endure daily use.

Conclusion

OEM galvanized chipboard nails are more than just simple fasteners; they are vital components in the construction and manufacturing industries. Their unique properties, such as corrosion resistance and durability, make them an excellent choice for anyone looking to ensure the longevity and reliability of their projects. As the demand for high-quality, durable materials continues to rise, the importance of using OEM products like galvanized chipboard nails will only become more pronounced. Investing in quality fasteners not only enhances the overall quality of the finished product but also contributes to the safety and satisfaction of the end user.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024