oem drywall ceiling screw spacing

Understanding OEM Drywall Ceiling Screw Spacing A Comprehensive Guide

When it comes to constructing or renovating interior spaces, drywall (also known as gypsum board) is a popular choice for walls and ceilings. It offers various advantages, such as speed of installation, ease of finishing, and cost-effectiveness. However, to achieve optimal results, understanding proper screw spacing is crucial, especially in the context of OEM (Original Equipment Manufacturer) drywall systems. This article delves into the importance of screw spacing in drywall ceiling installation and how it affects the overall performance and longevity of the structure.

Importance of Proper Screw Spacing

Screw spacing refers to the distance between each screw used to secure drywall sheets to framing members, such as studs or joists. This spacing plays a pivotal role in ensuring the durability and stability of the drywall installation. Proper screw spacing prevents problems such as sagging, cracking, and buckling, all of which can compromise both aesthetics and structural integrity. In the case of drywall ceilings, these issues are particularly noticeable due to gravity's effects.

Recommended Screw Spacing Guidelines

The general rule for screw spacing when installing drywall on ceilings is to place screws every 12 inches along the edges and every 16 inches in the field (the central area of the panel). However, the specific spacing can vary based on several factors, including the thickness of the drywall, the type of framing, and any applicable building codes. Here's a more detailed overview

1. Thickness of Drywall Standard drywall thickness for ceilings is typically 5/8 inch due to its fire resistance and soundproofing qualities. For this thickness, the screw spacing should generally adhere to the 12-inch and 16-inch guidelines mentioned above.

2. Framing Type In cases where drywall is installed over metal framing, the screw spacing may need adjustment. Metal studs can sometimes require more frequent screw placement to secure the drywall adequately, often mandating screws every 12 inches both at the edges and in the field.

oem drywall ceiling screw spacing

3. Building Codes Always consult local building codes and regulations, as they will dictate specific requirements for drywall installation in your area. Adhering to these regulations is essential for safety and compliance with legal standards.

Installation Techniques

Proper installation techniques complement the guidelines for screw spacing. Here are some tips to ensure an effective drywall ceiling installation

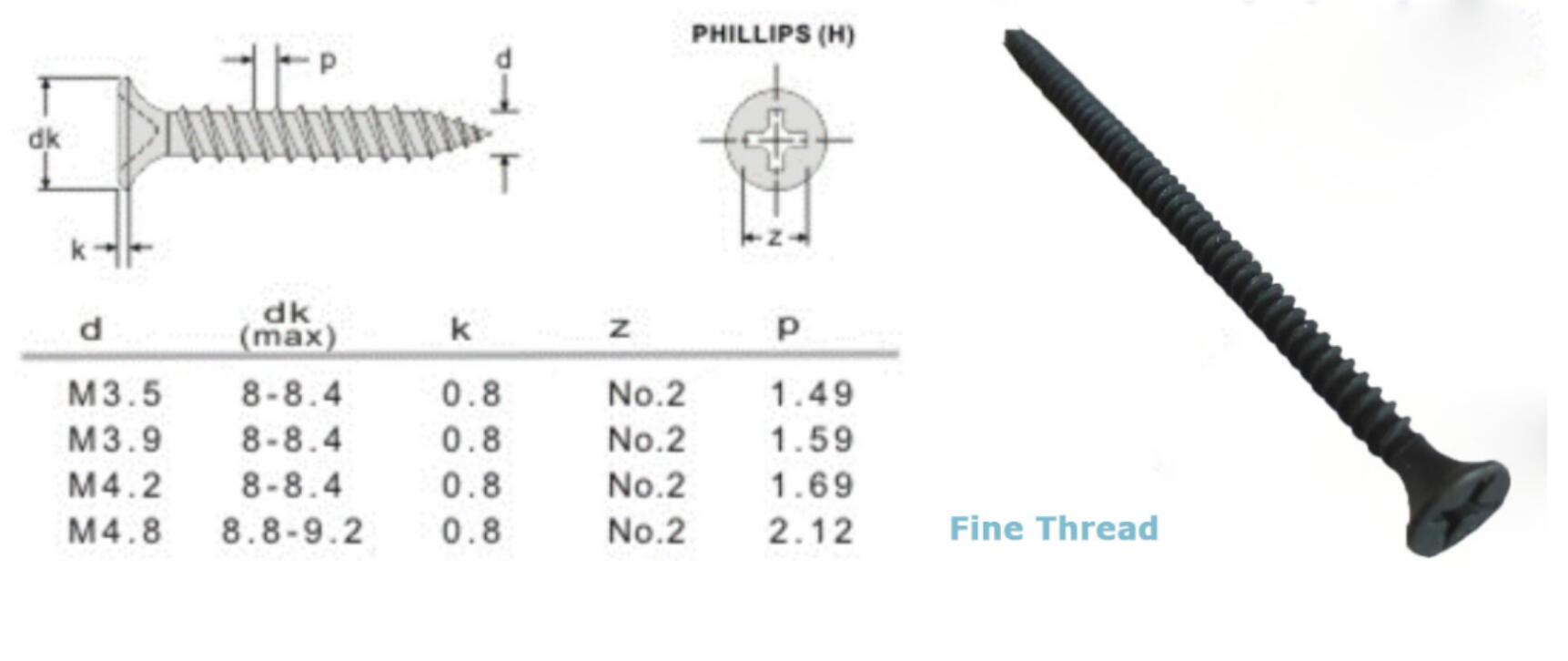

- Use Quality Screws OEM drywall screws are designed specifically for drywall installations and feature a bugle head that allows for a smooth finish. They should penetrate the drywall and into the framing without breaking through the paper face.

- Check for Level Always ensure that your framing is level before hanging drywall. Uneven framing can lead to uneven screw placement, further exacerbating issues with sagging or cracking.

- Avoid Overdriving Screws When securing the drywall, ensure that screws are driven just below the surface of the paper face without breaking through it. Overdriving can cause damage to the drywall and result in a poor finish.

Conclusion

Correct screw spacing is a fundamental aspect of installing drywall ceilings, particularly within OEM drywall systems. By adhering to recommended guidelines, utilizing quality materials, and implementing effective installation techniques, builders and DIY enthusiasts can create durable and aesthetically pleasing ceilings that stand the test of time. Understanding these principles not only enhances the visual appeal of interior spaces but also ensures safety and structural integrity, making it an integral part of drywall construction. Whether you're a professional contractor or a budding DIYer, mastering screw spacing will greatly contribute to the success of your drywall projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024