Jun . 26, 2024 01:56

Back to list

OEM Self-Drilling Hex Head Screw Sizes Comprehensive Guide

Understanding OEM Self-Drilling Hex Head Screw Sizes for Enhanced Efficiency

In the world of manufacturing and engineering, precision is paramount. One crucial component that exemplifies this principle is the self-drilling hex head screw. These specialized fasteners, commonly used in Original Equipment Manufacturer (OEM) applications, offer a unique combination of drilling and tapping capabilities, streamlining the assembly process and enhancing efficiency.

A self-drilling screw, as the name suggests, eliminates the need for a separate drilling operation. It features a sharp point and cutting threads that can pierce through metal, wood, or plastic, making it an ideal choice for various industries, from construction to automotive. The hex head, on the other hand, provides a secure grip for a wrench or socket, ensuring efficient tightening and reducing the risk of slippage.

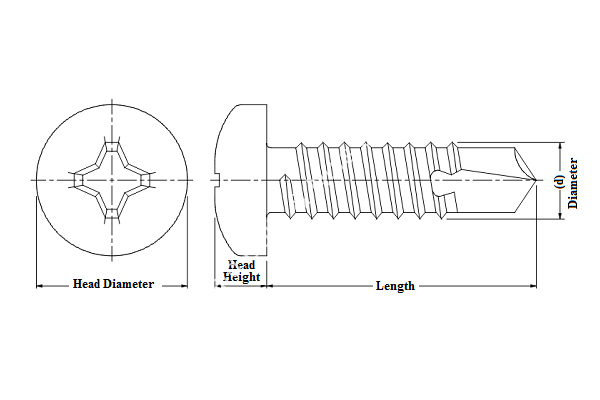

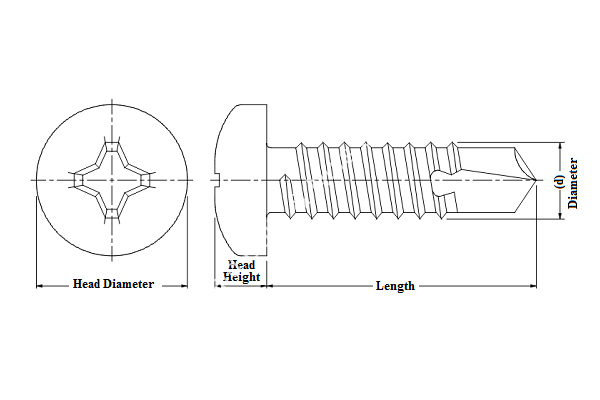

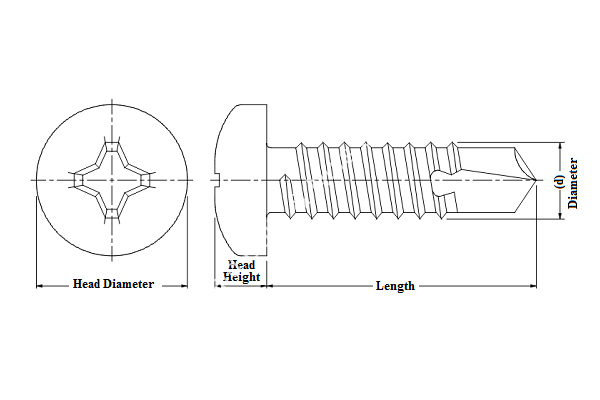

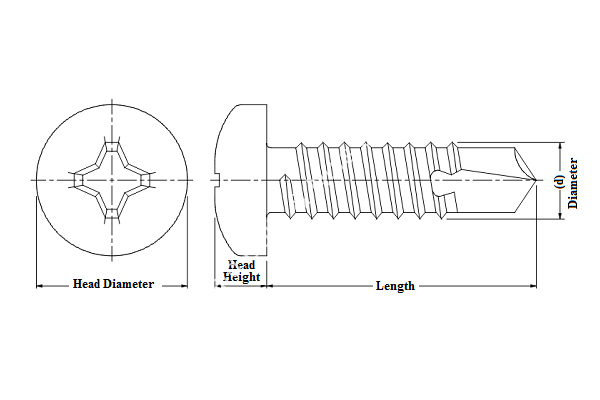

When it comes to sizes, self-drilling hex head screws follow a standardized system. In the United States, this typically involves the Unified Thread Standard (UTS), which defines both the diameter and pitch of the screw thread. The size is usually indicated by two numbers, such as 8 or 1/4, denoting the nominal diameter. The first number refers to the diameter in inches, while the second number indicates the size of the hexagon head.

Beyond the diameter, the length of the screw is another critical dimension. This can range from short screws designed for thin materials to longer ones used for heavier applications. Length is generally measured from under the head, accounting for the entire threaded section Length is generally measured from under the head, accounting for the entire threaded section Length is generally measured from under the head, accounting for the entire threaded section Length is generally measured from under the head, accounting for the entire threaded section

Length is generally measured from under the head, accounting for the entire threaded section Length is generally measured from under the head, accounting for the entire threaded section oem self drilling hex head screw sizes.

The thread count also plays a significant role in determining the screw's holding power. A higher thread count usually means better holding strength but may require more torque to install. It's essential to choose the right thread count based on the material and application requirements.

In the context of OEM usage, self-drilling hex head screws often come in customized sizes to fit specific machinery or components. Manufacturers may opt for smaller screws for intricate assemblies or larger ones for more robust structures. Ensuring the correct size is crucial to maintain structural integrity and prevent damage to the workpiece.

In conclusion, understanding the nuances of OEM self-drilling hex head screw sizes is vital for effective design and manufacturing processes. The right size can significantly improve productivity, reduce labor costs, and ensure the durability of the final product. Always consult with industry experts or refer to engineering guidelines to make informed decisions about the appropriate size for your specific application. Remember, the key to success lies in the details, and in this case, those details are measured in threads, diameters, and lengths of these indispensable fasteners.

oem self drilling hex head screw sizes.

The thread count also plays a significant role in determining the screw's holding power. A higher thread count usually means better holding strength but may require more torque to install. It's essential to choose the right thread count based on the material and application requirements.

In the context of OEM usage, self-drilling hex head screws often come in customized sizes to fit specific machinery or components. Manufacturers may opt for smaller screws for intricate assemblies or larger ones for more robust structures. Ensuring the correct size is crucial to maintain structural integrity and prevent damage to the workpiece.

In conclusion, understanding the nuances of OEM self-drilling hex head screw sizes is vital for effective design and manufacturing processes. The right size can significantly improve productivity, reduce labor costs, and ensure the durability of the final product. Always consult with industry experts or refer to engineering guidelines to make informed decisions about the appropriate size for your specific application. Remember, the key to success lies in the details, and in this case, those details are measured in threads, diameters, and lengths of these indispensable fasteners.

Length is generally measured from under the head, accounting for the entire threaded section Length is generally measured from under the head, accounting for the entire threaded section

Length is generally measured from under the head, accounting for the entire threaded section Length is generally measured from under the head, accounting for the entire threaded section oem self drilling hex head screw sizes.

The thread count also plays a significant role in determining the screw's holding power. A higher thread count usually means better holding strength but may require more torque to install. It's essential to choose the right thread count based on the material and application requirements.

In the context of OEM usage, self-drilling hex head screws often come in customized sizes to fit specific machinery or components. Manufacturers may opt for smaller screws for intricate assemblies or larger ones for more robust structures. Ensuring the correct size is crucial to maintain structural integrity and prevent damage to the workpiece.

In conclusion, understanding the nuances of OEM self-drilling hex head screw sizes is vital for effective design and manufacturing processes. The right size can significantly improve productivity, reduce labor costs, and ensure the durability of the final product. Always consult with industry experts or refer to engineering guidelines to make informed decisions about the appropriate size for your specific application. Remember, the key to success lies in the details, and in this case, those details are measured in threads, diameters, and lengths of these indispensable fasteners.

oem self drilling hex head screw sizes.

The thread count also plays a significant role in determining the screw's holding power. A higher thread count usually means better holding strength but may require more torque to install. It's essential to choose the right thread count based on the material and application requirements.

In the context of OEM usage, self-drilling hex head screws often come in customized sizes to fit specific machinery or components. Manufacturers may opt for smaller screws for intricate assemblies or larger ones for more robust structures. Ensuring the correct size is crucial to maintain structural integrity and prevent damage to the workpiece.

In conclusion, understanding the nuances of OEM self-drilling hex head screw sizes is vital for effective design and manufacturing processes. The right size can significantly improve productivity, reduce labor costs, and ensure the durability of the final product. Always consult with industry experts or refer to engineering guidelines to make informed decisions about the appropriate size for your specific application. Remember, the key to success lies in the details, and in this case, those details are measured in threads, diameters, and lengths of these indispensable fasteners. Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News