OEM screw has come loose and fallen out of drywall, causing potential structural issues.

Understanding OEM Screws and Common Issues with Drywall Installations

The construction and renovation industry relies heavily on a variety of hardware components, and OEM screws are among the most critical. The term OEM stands for Original Equipment Manufacturer, which means these screws are specifically designed by the manufacturer to meet the specifications of a particular device or system. When it comes to drywall installation, using the right screws is crucial for ensuring stability and a long-lasting finish. However, encountering problems like screws falling out of drywall can pose significant challenges for both homeowners and contractors.

The Importance of Right Screws

When installing drywall, the choice of screws can greatly influence the overall quality of the work. OEM screws are often designed for specific applications, which can provide better compatibility and performance than generic alternatives. They are made from high-strength materials and are engineered to resist stripping and corrosion, making them ideal for interior and exterior applications. Using the right screws not only helps in achieving a secure hold but also plays a role in protecting the integrity of the walls over time.

Reasons for Screws Falling Out of Drywall

Despite the advantages of OEM screws, issues can arise that lead to them falling out of drywall. Here are some common factors to consider

1. Improper Installation One of the most frequent causes of screws falling out is improper installation. Driving a screw in at an incorrect angle, not pre-drilling, or using insufficient depth can compromise its hold. If the screw does not engage enough of the drywall material, it may loosen and eventually fall out.

2. Overloading Each type of drywall screw is rated for a specific load. Overloading the drywall with heavy items, such as shelves or cabinets, can result in screws being pulled out. This is particularly common in cases where weight distribution is not properly managed.

3. Moisture Damage Drywall is prone to damage from moisture, which can weaken the surrounding material. Areas exposed to humidity or water over time might suffer from degradation, causing screws to lose their grip and fall out.

oem screw fell out of drywall

4. Material Quality While OEM screws are designed for specific applications, not all screws are created equal. Poor-quality screws, or those that are not suited for drywall, may corrode or break over time. It is essential to choose high-quality screws that are appropriate for the drywall and the environment in which they are installed.

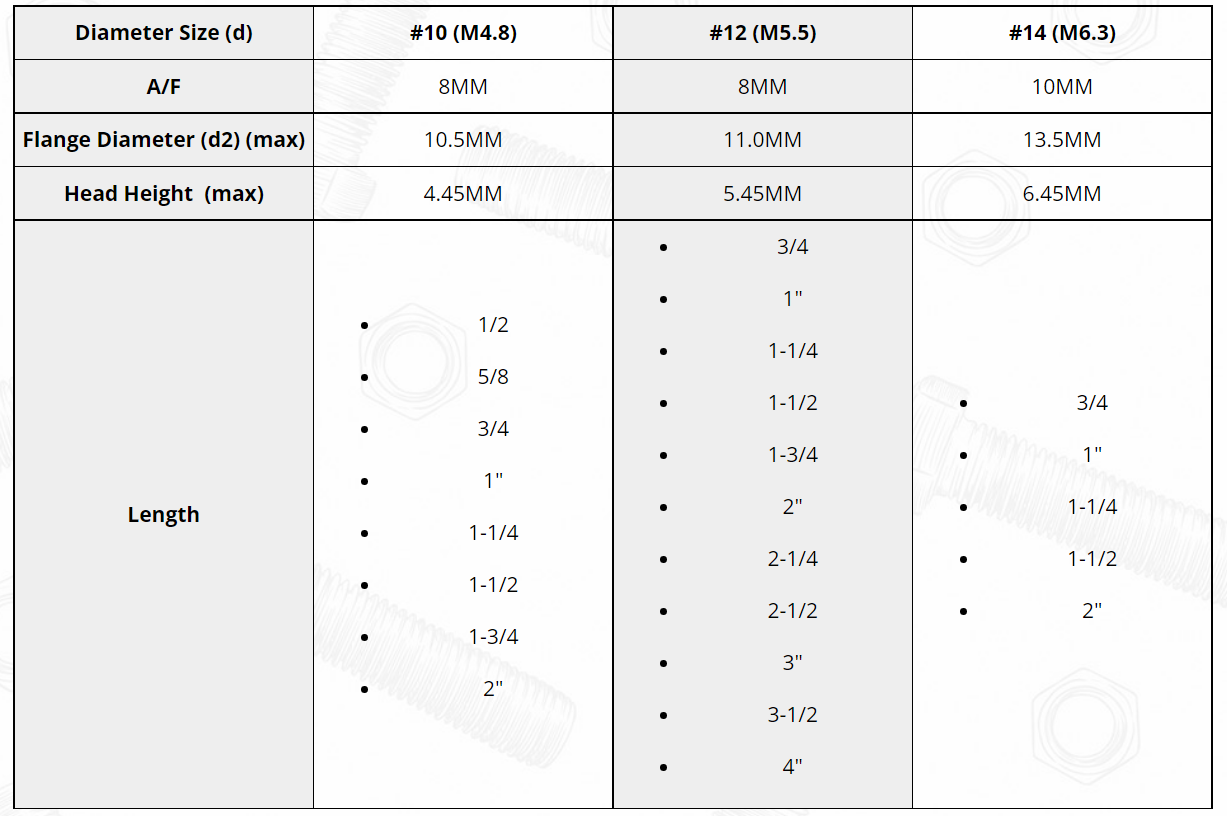

5. Drywall Thickness The thickness of the drywall also plays a role in screw stability. Standard drywall comes in varying thicknesses (e.g., 1/2 inch or 5/8 inch). Choosing the wrong screw length for the thickness of the drywall can lead to inadequate anchoring and eventual failure.

Solutions to Prevent Screws from Falling Out

To prevent screws from falling out of drywall, several strategies can be employed

- Pre-Drill Holes Pre-drilling helps prevent the drywall from cracking and allows for more precise control when installing screws.

- Use Appropriate Length and Type Ensure that the screws used are appropriate for the thickness of the drywall. For instance, 1 1/4 inch screws are typically sufficient for 1/2 inch drywall.

- Adhere to Loading Guidelines Always refer to the weight capacity of screws and anchors and avoid exceeding these limits.

- Repair Moisture Issues Address any sources of moisture before installing drywall to maintain the integrity of the material.

In conclusion, while OEM screws are designed for optimal performance in drywall applications, they can still fall out due to several common issues. Understanding the reasons behind this problem and employing best practices during installation can help ensure a secure and lasting drywall finish. Restoration and repair may be necessary, but proactive measures can significantly reduce the likelihood of encountering these challenges.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024