oem bolt washer spring washer nut order

The Importance of OEM Bolt, Washer, Spring Washer, and Nut Orders in Industrial Applications

In the world of industrial manufacturing and engineering, the significance of OEM (Original Equipment Manufacturer) parts cannot be overstated. Among these essential components, bolts, washers, spring washers, and nuts play a critical role in maintaining the integrity and functionality of machinery. Understanding the importance of these components and how to effectively order them can greatly enhance operational efficiency.

Understanding OEM Components

OEM components are parts made by the original manufacturer to fit specific machinery, ensuring high compatibility and reliability. This is particularly crucial when it comes to bolts, washers, spring washers, and nuts. Each component serves a distinct purpose; bolts provide fastening strength, washers distribute load and prevent corrosion, spring washers absorb shock and vibration, and nuts secure the bolts in place. Together, they create robust assemblies that withstand the rigors of industrial operations.

Streamlining the Ordering Process

To ensure optimal performance, it is essential to place accurate and efficient orders for these components. A well-structured order process should include several key steps

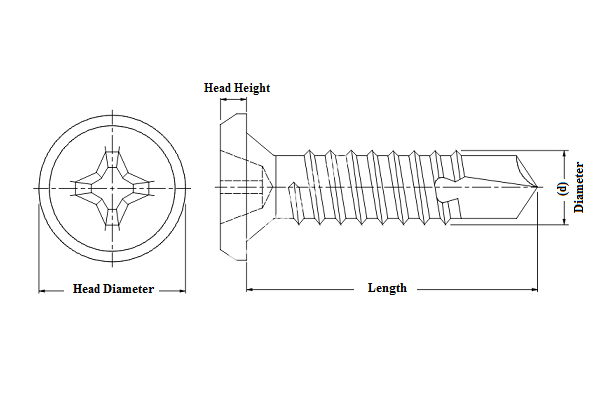

1. Identify Specifications Before placing an order, it's vital to identify the specifications required for each component. This includes dimensions, materials, and load ratings. For instance, a high-strength steel bolt may be necessary for heavy machinery, while a stainless steel washer might be preferred in corrosive environments.

oem bolt washer spring washer nut order

2. Select Reliable Suppliers Partnering with trusted suppliers who specialize in OEM parts is crucial. They should have a reputation for quality and precision, ensuring that the components meet industry standards. When selecting suppliers, consider their manufacturing capabilities, delivery speed, and customer service.

3. Utilize OEM Catalogs Many suppliers offer catalogs that provide detailed information about their products. These catalogs can be invaluable for making informed decisions when selecting bolts, washers, and nuts. They typically include diagrams, material specifications, and application guidelines, which can help streamline the ordering process.

4. Quantity and Inventory Management Carefully assess your inventory needs. Ordering in bulk may lead to cost savings, but it’s essential to balance this with storage capabilities and the need for just-in-time delivery. Implementing inventory management systems can help track usage patterns and forecast requirements accurately.

5. Quality Assurance Before finalizing an order, ensure that quality assurance measures are in place. This can include requesting product samples, checking certifications, and confirming compliance with industry standards. Quality components are vital for preventing failures and ensuring safety.

Conclusion

In conclusion, the proper ordering of OEM bolts, washers, spring washers, and nuts is fundamental to the reliability of machinery and equipment in industrial applications. By understanding component specifications, selecting reliable suppliers, utilizing catalogs, managing inventory wisely, and ensuring quality assurance, businesses can optimize their operations and enhance overall productivity. As industries continue to evolve, staying ahead with quality OEM parts will remain a key factor in achieving long-term success.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024