Self-Drilling Screws for ODM Truss Applications and Structural Support Solutions

Understanding ODM Truss Self-Drilling Screws

In the realm of construction and engineering, the choice of fasteners plays a pivotal role in the structural integrity and longevity of a project. Among the various types of fasteners, self-drilling screws, particularly ODM (Original Design Manufacturer) truss self-drilling screws, have gained immense popularity due to their efficiency and reliability. This article explores the features, applications, advantages, and considerations associated with ODM truss self-drilling screws.

What Are ODM Truss Self-Drilling Screws?

ODM truss self-drilling screws are specialized fasteners designed to penetrate and secure materials without the need for pre-drilling. The self-drilling feature refers to the tip of the screw, which is engineered to drill its own hole as it is driven into the material. The term truss refers to the shape of the screw head, which is typically wider and flatter compared to conventional screw heads, providing a larger bearing surface and better load distribution.

These screws are often used in the assembly of metal structures, such as truss systems in roofs and bridges, where materials require secure fastening in challenging environments. The versatility and effectiveness of these screws make them an essential component in modern construction.

Key Features of ODM Truss Self-Drilling Screws

1. Self-Drilling Capability One of the standout features is their ability to drill through metal or other materials quickly. This reduces the time and labor costs associated with pre-drilling holes.

2. Weather Resistance ODM truss self-drilling screws are usually coated with corrosion-resistant materials, ensuring durability even in harsh weather conditions. This characteristic is vital for outdoor constructions where moisture and environmental factors can compromise the integrity of fasteners.

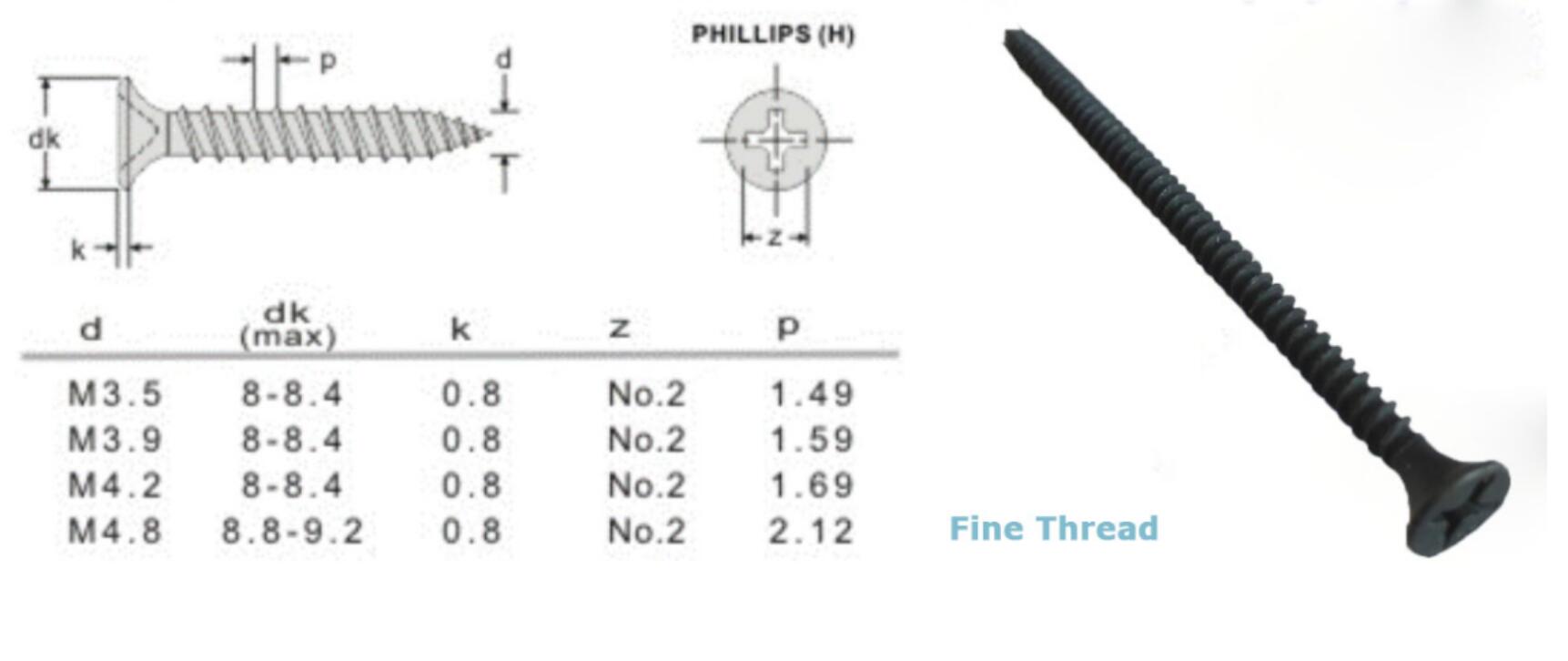

3. Various Sizes and Material Options These screws come in various sizes and grades, allowing for tailored solutions depending on the specific needs of a project. They are commonly made from steel, stainless steel, or other alloys to provide adequate strength and performance.

4. Easy Installation The design allows for rapid installation, saving significant time during the construction process. The truss head design also helps in reducing the risk of cam-out, which occurs when the driver slips off the head of the screw.

Applications in Construction

odm truss self drilling screw

The applications of ODM truss self-drilling screws are vast and varied. They are frequently used in

- Metal Buildings These screws are ideal for connecting metal framing components, facilitating quick and robust assembly. - Roofing Systems The weather-resistant properties make them suitable for securing roofing panels and systems. - Transport Structures In bridges and similar infrastructures, the screws provide the necessary strength and reliability to withstand heavy loads and environmental stresses. - Manufactured Homes and Modular Structures They are extensively employed in prefab construction, where speed and efficiency are paramount.

Advantages of Using ODM Truss Self-Drilling Screws

The use of ODM truss self-drilling screws comes with numerous benefits

- Cost-Effectiveness While the initial investment may be higher than standard screws, the time saved in installation and the reduced need for additional tools (like drills) can lead to overall cost savings. - Increased Efficiency The self-drilling nature allows for faster assembly, which can significantly expedite project timelines. - Enhanced Structural Integrity With their ability to create strong, secure connections, these screws contribute to the overall durability and resilience of the structure.

Considerations When Using ODM Truss Self-Drilling Screws

While ODM truss self-drilling screws offer numerous benefits, there are a few considerations to keep in mind

- Material Compatibility It is essential to ensure that the screw type is compatible with the materials being joined to avoid stripped threads or inadequate fastening. - Application Environment Be mindful of environmental conditions. In environments with extreme temperatures or corrosive elements, select screws with appropriate coatings. - Installation Tools Although they eliminate the need for pre-drilling, using the correct driver and torque setting is crucial to avoid damaging the screw or the materials.

Conclusion

ODM truss self-drilling screws represent a significant advancement in fastening technology, particularly in the construction industry. Their thoughtful design, coupled with the advantages they offer, makes them an excellent choice for various applications, from metal buildings to roofing systems. When used appropriately, they not only enhance the efficiency of installation but also contribute to the structural integrity and longevity of construction projects. As the industry continues to evolve, understanding and leveraging such innovative fasteners will remain essential for successful engineering solutions.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024