odm 8 self tapping screw diameter

Understanding ODM 8% Self-Tapping Screw Diameter Key Considerations for Construction and Manufacturing

In the realm of construction and manufacturing, precision is paramount. One element that plays an integral role in ensuring structural integrity and reliability is the self-tapping screw. Among various specifications, the ODM (Outside Diameter Measurement) of a self-tapping screw, specifically at 8%, is a topic worth delving into due to its implications on material performance, application suitability, and overall project success.

What is a Self-Tapping Screw?

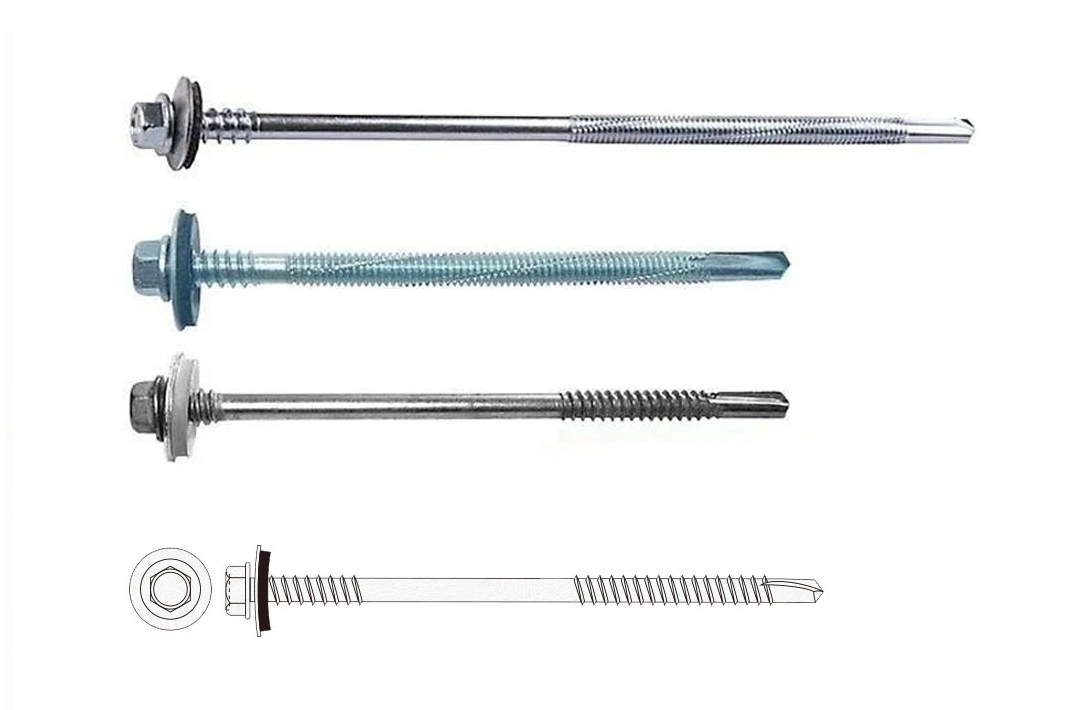

Self-tapping screws are a type of fastener designed to create their own hole when driven into materials. They are particularly advantageous in a variety of applications, from woodworking to metal construction. The unique design allows them to bore into existing materials without the need for pre-drilled holes, saving time and effort in assembly processes.

Importance of Diameter in Self-Tapping Screws

The diameter of a self-tapping screw is a critical parameter, influencing both the screw's load-bearing capacity and its suitability for specific materials. Generally, the diameter measurement is denoted in gauge sizes or as a nominal size in millimeters or inches. An ODM of 8% signifies a specific tolerance level, ensuring the screw achieves a balance between grip and ease of installation.

When selecting a self-tapping screw, understanding the diameter is essential for several reasons

1. Load Capacity The diameter directly correlates with the screw’s ability to hold weight. A larger diameter typically provides greater strength, which is crucial when fasteners are expected to support heavy loads or withstand tensile forces.

2. Material Compatibility Different materials require specific screw diameters to ensure an effective bond. For instance, wood and metal have different requirements in terms of slip resistance and shear strength, which are intertwined with the screw diameter.

3. Installation Ease The relationship between screw diameter and the substrate material can affect how easily a screw can be installed. An appropriately sized screw minimizes the risk of cracking or splitting the substrate, which is particularly relevant in woodworking projects.

Applications of 8% ODM Self-Tapping Screws

odm 8 self tapping screw diameter

The application of an 8% ODM self-tapping screw is wide-ranging. In the HVAC industry, for example, these screws are used for securing ductwork where a tight, reliable connection is essential to prevent leaks and ensure efficiency. In automotive manufacturing, self-tapping screws facilitate the assembly of various components, allowing for streamlined production processes.

Furthermore, the 8% specification can be tailored to specific project needs. This adaptability makes these screws suitable for applications such as

- Furniture Assembly Flat-pack furniture often relies on self-tapping screws for quick and efficient construction. - Metal Fabrication When connecting metal components, the precision of the diameter becomes critical to avoid stripping and ensure durability. - Electrical Installations In places where wires and components need secure fastening, the choice of screw can greatly affect safety and functionality.

Considerations When Choosing Self-Tapping Screws

When selecting the appropriate self-tapping screw, especially one with an ODM of 8%, several factors should be taken into consideration

1. Coating and Corrosion Resistance Depending on the environment in which the screws will be used (e.g., outdoor vs. indoor), the need for a corrosion-resistant coating, such as zinc plating, may arise.

2. Length of the Screw The length must correspond not only to the thickness of the materials being fastened but also allow sufficient engagement to maximize holding power.

3. Head Style Different head styles (e.g., flat, pan, or round) can influence both aesthetics and functionality, such as whether a flush finish is necessary.

4. Thread Design The thread type—coarse or fine—also plays a role in how effectively a screw can penetrate a material.

Conclusion

In summary, understanding the intricacies of ODM 8% self-tapping screw diameter is crucial for anyone involved in construction or manufacturing. The diameter impacts not only the performance and suitability of the screw for specific applications but also the overall efficiency of assembly and durability of final products. As projects demand higher standards of precision and reliability, the significance of choosing the correct self-tapping screw cannot be understated.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024