Feb . 11, 2025 18:35

Back to list

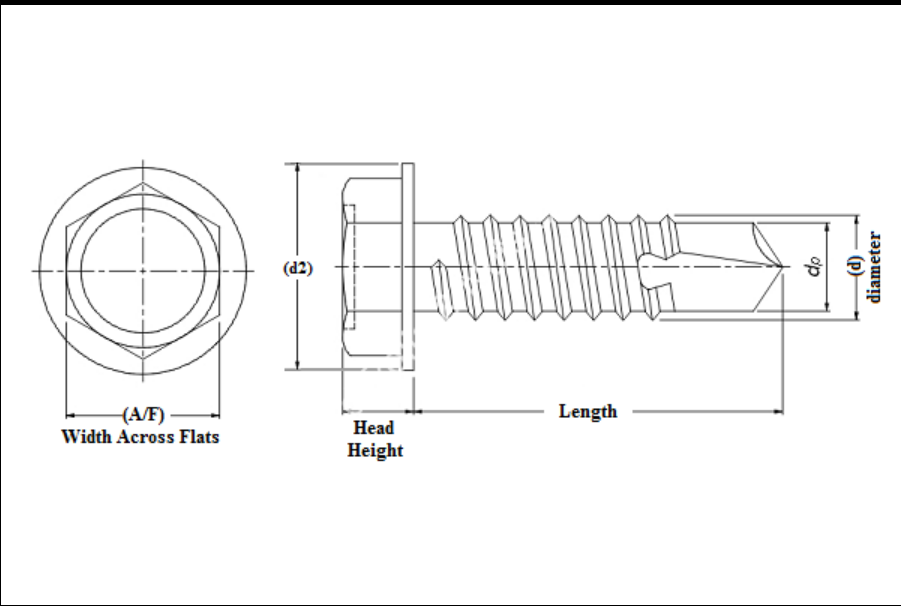

number 10 self tapping screw

For anyone invested in construction, home improvement, or even small-scale DIY projects, choosing the right fasteners can make a significant difference in the outcome of your work. The number 10 self-tapping screw remains a popular choice among professionals and hobbyists due to its versatility, strength, and ease of use. Here’s an in-depth look at why this particular screw is the go-to option for many, based on extensive experience, technical expertise, and assured reliability.

Trustworthiness in product selection is built on reliability and user satisfaction over time. Number 10 self-tapping screws have consistently demonstrated their reliability by maintaining their hold, even under harsh conditions. This dependability ensures that structures withstand environmental challenges, such as temperature changes and physical stresses, without compromising their integrity. This attribute is particularly valued in construction and marine applications where corrosion resistance is necessary for longevity. User testimonials further reinforce the trust in these screws. Builders and DIY enthusiasts have noted the substantial time saved during projects by using self-tapping screws, which do not require pre-drilling. The ease of use and reduced tool requirements simplify the process, making them accessible even to non-professionals, while also maintaining the high-quality results expected from seasoned experts. In conclusion, the number 10 self-tapping screw epitomizes excellence in fastening technology. It suits a wide array of applications, balances strength with convenience, and is backed by professional endorsement, regulatory compliance, and proven user satisfaction. Its capability to deliver reliable and secure fastening solutions underscores its status as an indispensable tool for both novices and seasoned professionals. Whether renovating a home, repairing vehicles, or constructing new structures, the number 10 self-tapping screw stands ready to meet the demands of any project with efficiency and reliability.

Trustworthiness in product selection is built on reliability and user satisfaction over time. Number 10 self-tapping screws have consistently demonstrated their reliability by maintaining their hold, even under harsh conditions. This dependability ensures that structures withstand environmental challenges, such as temperature changes and physical stresses, without compromising their integrity. This attribute is particularly valued in construction and marine applications where corrosion resistance is necessary for longevity. User testimonials further reinforce the trust in these screws. Builders and DIY enthusiasts have noted the substantial time saved during projects by using self-tapping screws, which do not require pre-drilling. The ease of use and reduced tool requirements simplify the process, making them accessible even to non-professionals, while also maintaining the high-quality results expected from seasoned experts. In conclusion, the number 10 self-tapping screw epitomizes excellence in fastening technology. It suits a wide array of applications, balances strength with convenience, and is backed by professional endorsement, regulatory compliance, and proven user satisfaction. Its capability to deliver reliable and secure fastening solutions underscores its status as an indispensable tool for both novices and seasoned professionals. Whether renovating a home, repairing vehicles, or constructing new structures, the number 10 self-tapping screw stands ready to meet the demands of any project with efficiency and reliability.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News