Top Self-Tapping Screw Manufacturers and Their Best Products

The Evolution and Importance of No. 208 Self-Tapping Screws in Modern Manufacturing

Self-tapping screws have become indispensable components in construction and manufacturing, serving a myriad of applications across various industries. Among them, the No. 208 self-tapping screw has carved a niche due to its unique design features and functional advantages. This article explores the characteristics, applications, and companies that specialize in producing No. 208 self-tapping screws, highlighting their significance in modern engineering and manufacturing processes.

Understanding No. 208 Self-Tapping Screws

The No. 208 self-tapping screw is characterized by its ability to create its own hole as it is driven into the material. This feature minimizes the need for pre-drilling, making them ideal for fast-paced assembly lines. Typically made from high-strength materials such as steel or stainless steel, these screws are coated for enhanced corrosion resistance, which is crucial for durability in various environments.

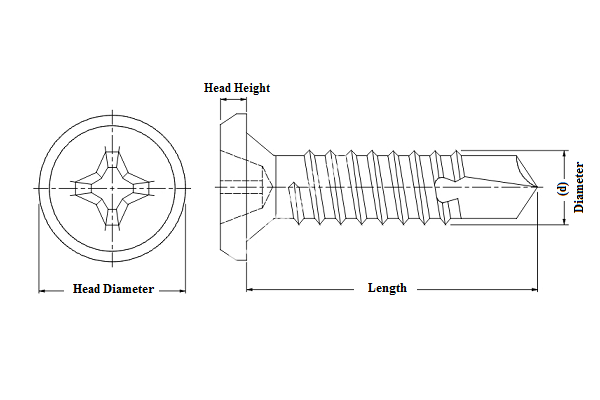

In terms of specifications, the No. 208 refers to its diameter (roughly 2.68mm) and length, which is generally around 8mm. The thread design is engineered to facilitate a secure hold in materials ranging from wood to metal, offering versatility for different applications. The self-tapping mechanism allows for faster installation and improved efficiency, significantly contributing to productivity in manufacturing.

Applications of No. 208 Self-Tapping Screws

The No. 208 self-tapping screw finds applications across a wide spectrum of industries. In the automotive sector, these screws are crucial for assembling components and securing parts within vehicles. The electronics industry utilizes No. 208 screws in assembling devices where a secure connection is paramount but space is limited. Furthermore, in the construction industry, these screws are commonly used for fastening drywall, securing roofing materials, and in various furniture assemblies, owing to their ease of use and strength.

One of the standout features of No. 208 self-tapping screws is their ability to be used in metal-to-metal applications. With the advent of lightweight materials in manufacturing, the need for screws that can maintain structural integrity while being lightweight is ever-present. No. 208 screws provide that balance, fostering innovation in design and application.

Companies Specializing in No. 208 Self-Tapping Screws

no 8 self tapping screw companies

Numerous companies manufacture No. 208 self-tapping screws, each bringing unique expertise and technology to the table. Some leading companies in this sector include

1. Fastenal - Known for its wide range of industrial and construction fastening solutions, Fastenal is a reliable source for self-tapping screws, including the No. 208 variant. They offer extensive online resources for selecting the right screw for any application.

2. Hillman Group - With a strong presence in the hardware industry, Hillman provides a variety of self-tapping screws, ensuring high-quality products tailored to the demands of both consumers and professionals.

3. ITW (Illinois Tool Works) - A leader in engineered fastening solutions, ITW produces self-tapping screws with advanced design features, ensuring strength and reliability for critical applications.

4. Monroe Engineering - This company specializes in custom screws and fasteners, including No. 208 self-tapping screws. Their commitment to quality and customization makes them a go-to choice for businesses with specific requirements.

5. McMaster-Carr - Renowned for their extensive catalog of industrial supplies, McMaster-Carr offers a variety of self-tapping screws, including different materials and coatings to suit specific environmental conditions.

Conclusion

The No. 208 self-tapping screw stands as a testament to the advancements in fastening technology and manufacturing efficiency. Its design facilitates quick assembly and application across various industries, making it a staple in many engineering processes. As manufacturing continues to evolve and demand for reliable fasteners increases, the companies that specialize in creating high-quality No. 208 self-tapping screws are poised to remain at the forefront of innovation. Through their dedication to quality and efficiency, these screws will continue to play a crucial role in the construction, automotive, and electronics industries for years to come.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024