metric self tapping screw size chart manufacturers

Understanding Metric Self-Tapping Screw Size Charts

In the world of manufacturing and construction, understanding the specifics of fasteners is crucial for ensuring quality and safety. One of the most commonly used fasteners is the self-tapping screw, especially in metric sizes. These screws are designed to create their own hole as they are driven into the material, making them essential for various applications where precision and strength are required.

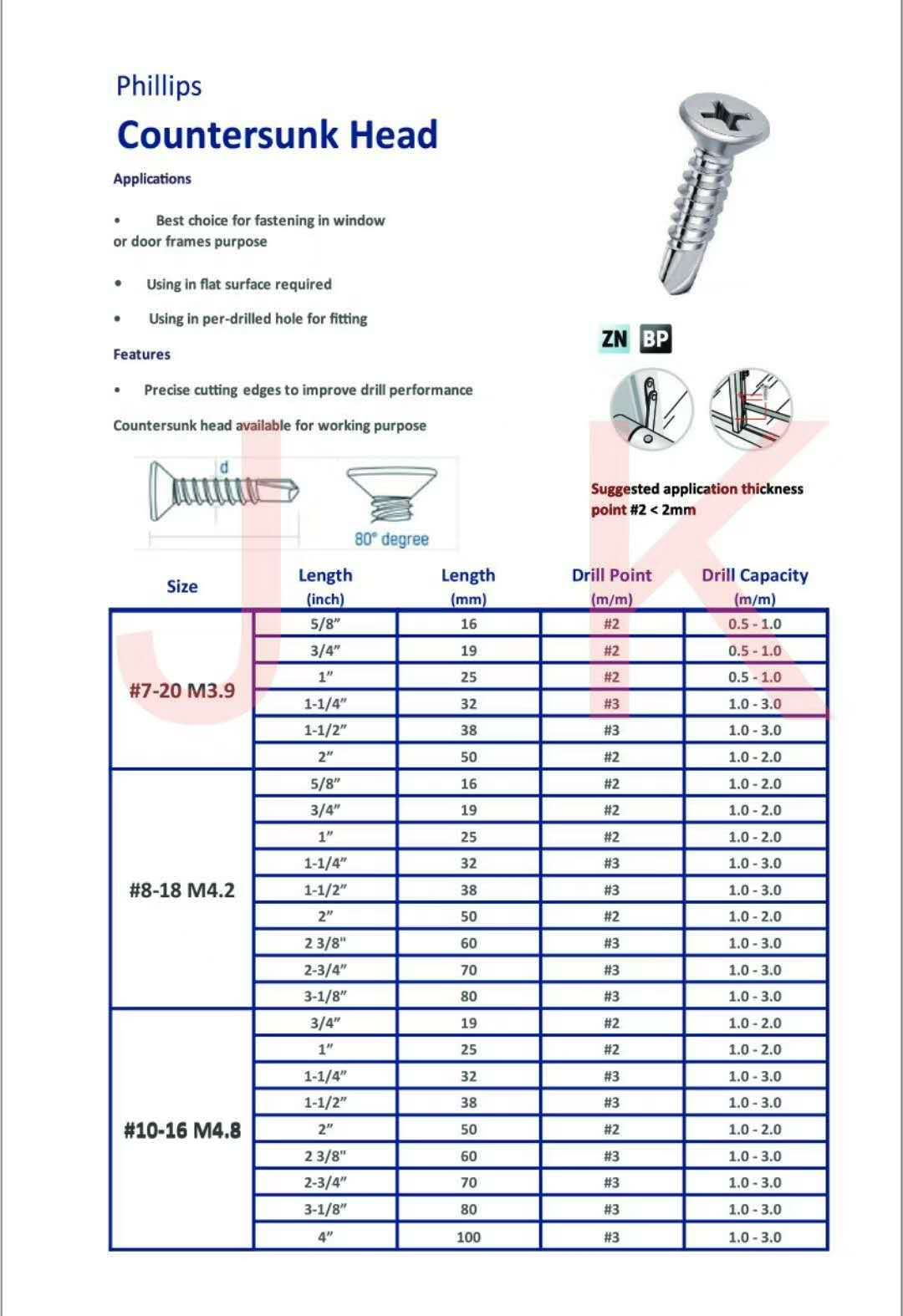

A metric self-tapping screw size chart is an invaluable tool for manufacturers, engineers, and DIY enthusiasts. It provides a comprehensive overview of the different sizes, lengths, and thread pitches available in the market. Typically, metric self-tapping screws are categorized by their diameter, which is usually measured in millimeters (mm). Common sizes range from M2.5 up to M10 and beyond, depending on the specific requirements of the project.

The size chart not only lists the diameters but also includes the length of the screws. Length is an important factor that dictates how deep the screw will penetrate the material, which is crucial for ensuring a secure grip. For example, for sheet metal applications, screws ranging from 10 mm to 50 mm in length are commonly used. The material thickness plays a significant role in determining the appropriate screw length to ensure optimal performance.

metric self tapping screw size chart manufacturers

Another important aspect covered in the size chart is the thread pitch, which indicates the distance between the threads. Metric self-tapping screws typically have coarse or fine threads, with coarse threads being preferred for softer materials and fine threads suited for harder materials. Understanding the right thread pitch is vital for ensuring that the screw engages properly with the material, minimizing the risk of stripping or failure.

Moreover, manufacturers often provide additional information such as the head type (e.g., pan, flat, hex) and the coating (e.g., zinc-plated, stainless steel) used on the screws. These details can impact the screw’s durability and suitability for specific environments, such as outdoor or corrosive settings.

In summary, a metric self-tapping screw size chart is an essential reference for anyone working with these fasteners. It facilitates informed decisions by providing critical information on size, length, thread pitch, and material compatibility. By using the correct screw for the job, manufacturers and craftsmen can enhance the integrity and longevity of their projects, leading to successful outcomes. Whether you are a seasoned professional or a novice, familiarity with this size chart will undoubtedly streamline your fastening processes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024