machine screw vs self tapping products

Understanding the Differences Between Machine Screws and Self-Tapping Screws

Fasteners play an essential role in various engineering and construction applications, ensuring that components are securely joined together. Among the most commonly used fasteners are machine screws and self-tapping screws. Despite their similar appearances and functionalities, these two types of screws have distinct characteristics, applications, and advantages that set them apart. This article will explore the differences between machine screws and self-tapping screws, helping you determine which type is more suitable for your specific project needs.

What are Machine Screws?

Machine screws are designed to fasten metal parts together and are typically used with a nut or in a pre-tapped hole. These screws are made with standardized dimensions and are available in various sizes, shapes, and materials, including stainless steel, brass, and plastic. They have uniform threads that provide consistent engagement with nuts or tapped holes, ensuring a strong connection.

Machine screws come in different head styles, such as flat, pan, round, and hex, which allows them to be used in different applications. The primary purpose of machine screws is to securely fasten two pieces of material while allowing for removal and reinstallation without compromising the integrity of the screw or the material it's fastened to.

What are Self-Tapping Screws?

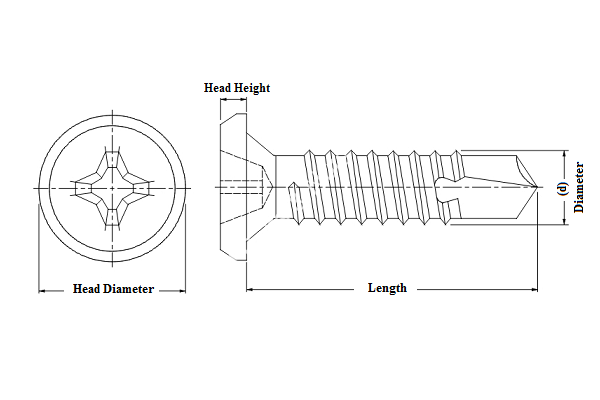

Self-tapping screws, on the other hand, are designed to create their own thread as they are driven into materials. This means that they do not require a pre-tapped hole, making them particularly useful for applications where drilling pilot holes would be impractical. Self-tapping screws are commonly used in softer materials, such as wood, plastic, and thin metal sheets.

These screws typically come with a sharp point that allows them to penetrate the material easily, and their threads are designed to cut into the substrate as they are installed. Self-tapping screws are available in various styles, including thread-cutting screws and thread-forming screws, each designed for specific applications.

Key Differences

machine screw vs self tapping products

1. Cutting vs. Tapping - Machine screws are used with pre-tapped holes or nuts, while self-tapping screws create their own threads in the material as they are installed. 2. Material Compatibility - Machine screws are typically used in applications where metal components are involved, whereas self-tapping screws are suitable for softer materials like wood and plastic.

3. Installation Process - Machine screws require a separate step for securing with a nut or pre-tapped hole, while self-tapping screws can be installed directly into the material, making them quicker and easier to use in some cases.

4. Strength and Stability - Machine screws generally offer superior strength and stability compared to self-tapping screws, making them ideal for applications requiring a robust fastening solution.

5. Reusability - Machine screws can often be reused multiple times due to their design, while self-tapping screws may lose some holding power after being removed from materials.

Applications

Given their differences, machine screws and self-tapping screws find their places in various applications. Machine screws are commonly found in machinery assemblies, automotive applications, and structural frameworks, where maximum stability is crucial. Their ability to form a secure connection with nuts makes them ideal for carrying heavy loads.

Self-tapping screws, however, are popular in home improvement projects, electronic casings, and light furniture assembly. Their ease of use allows homeowners and DIY enthusiasts to install fasteners quickly without advanced tools or techniques.

Conclusion

In summary, choosing the right type of screw is essential for ensuring the success of your project. Machine screws provide strength and stability for heavier applications, while self-tapping screws offer convenience and speed, especially in softer materials. Understanding the unique characteristics and applications of each type can help you make an informed decision that meets your project requirements. Whether you are a professional engineer or a DIY enthusiast, knowing when to use machine screws versus self-tapping screws can save you time and enhance the durability of your work.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024